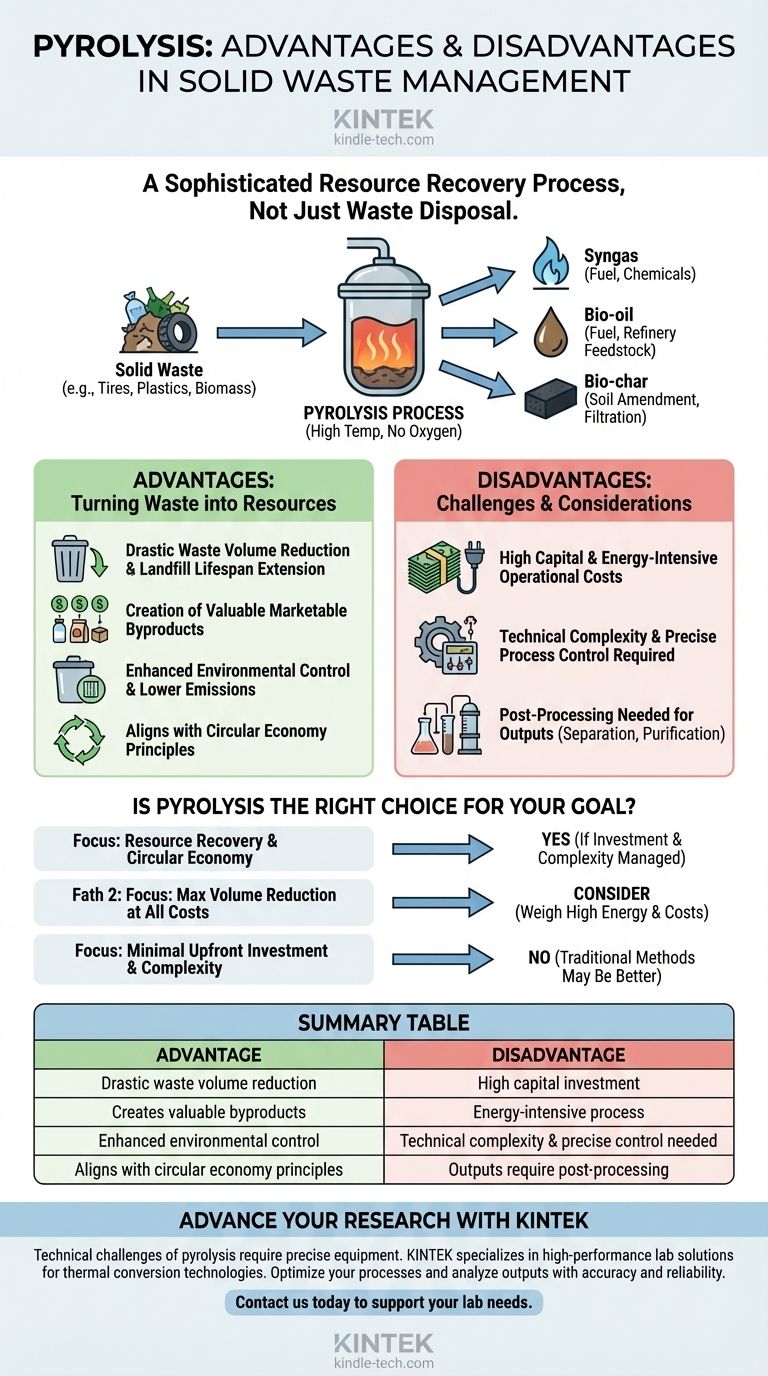

At its core, pyrolysis is a powerful waste conversion technology with the primary advantage of transforming solid waste into valuable resources like fuel and bio-char, significantly reducing landfill volume. However, its main disadvantages are the high capital investment required and its operational complexity, as it is an energy-intensive process that demands precise control.

Pyrolysis should be understood not as a simple waste disposal method, but as a sophisticated resource recovery process. This distinction is the key to appreciating both its significant potential and its demanding technical and financial requirements.

What is Pyrolysis in Waste Management?

Pyrolysis is a form of thermal treatment that fundamentally changes the chemical structure of waste materials. It's a technology aimed at reclamation rather than simple destruction.

The Core Process: Thermal Decomposition Without Oxygen

Pyrolysis involves heating organic-based solid waste, such as biomass, plastics, or tires, to high temperatures in an environment with little to no oxygen.

The absence of oxygen is critical. It prevents combustion (burning) and instead causes the materials to break down into smaller, more valuable molecules.

Key Inputs: What Waste Can Be Treated?

The process is most effective for specific types of solid waste. This typically includes materials like used tires, various types of plastics, and biomass such as wood chips or agricultural residue.

Valuable Outputs: From Waste to Resource

The process breaks down complex waste into three primary products, each with potential uses:

- Syngas: A mixture of combustible gases that can be used to generate electricity or as a feedstock for producing chemicals and fuels.

- Bio-oil (Pyrolysis Oil): A liquid fuel that can be refined for use in engines and boilers or upgraded into higher-grade transportation fuels.

- Bio-char: A stable, carbon-rich solid that can be used to amend and improve soil quality or be processed into activated carbon for filtration purposes.

The Primary Advantages of Pyrolysis

When implemented correctly, pyrolysis offers compelling benefits over traditional waste disposal methods like landfilling.

Drastic Waste Volume Reduction

The most immediate benefit is a significant decrease in the volume of waste requiring disposal. This directly extends the lifespan of existing landfills and reduces the need for new ones.

Creation of Valuable Byproducts

Instead of burying waste, pyrolysis converts it into marketable commodities. This creates a potential revenue stream that can offset operational costs and aligns with the principles of a circular economy.

Enhanced Environmental Control

Because pyrolysis occurs in a sealed, oxygen-free system, it offers a high degree of control over emissions compared to direct incineration. It captures the value within the waste rather than releasing it through uncontrolled burning.

Understanding the Disadvantages and Challenges

The potential of pyrolysis is balanced by significant practical and economic hurdles that must be carefully considered.

High Capital and Operational Costs

Pyrolysis plants require a substantial upfront investment in specialized equipment and infrastructure. The process is also energy-intensive, consuming a notable amount of power to maintain the high temperatures needed for decomposition.

Technical Complexity and Process Control

Achieving efficient and consistent results is not simple. The process requires specific and stable operating conditions, including precise temperature control and management of waste feedstock, demanding skilled operators and robust engineering.

The Need for Post-Processing

The outputs of pyrolysis—syngas, bio-oil, and bio-char—are not immediately ready for use. They often require separation, purification, and refinement to meet market specifications, adding another layer of complexity and cost to the overall operation.

Is Pyrolosis the Right Choice for Your Goal?

Evaluating pyrolysis requires aligning its capabilities with your primary waste management objectives.

- If your primary focus is resource recovery and creating a circular economy: Pyrolysis is a powerful contender, provided you can justify the high capital investment and manage the technical demands of a sophisticated chemical process.

- If your primary focus is reducing landfill volume at all costs: Pyrolysis is extremely effective at volume reduction, but you must weigh its high energy and operational costs against simpler thermal treatment options.

- If your primary focus is minimizing upfront investment and operational complexity: Traditional waste management methods or less complex conversion technologies may be more suitable for your immediate needs and budget.

Ultimately, viewing pyrolysis not as simple waste disposal but as a specialized manufacturing process that uses waste as a raw material is the key to evaluating its true potential.

Summary Table:

| Advantage | Disadvantage |

|---|---|

| Drastic waste volume reduction | High capital investment |

| Creates valuable byproducts (syngas, bio-oil, bio-char) | Energy-intensive process |

| Enhanced environmental control vs. incineration | Technical complexity & precise control needed |

| Aligns with circular economy principles | Outputs require post-processing |

Ready to explore advanced waste management solutions for your laboratory?

The technical challenges of pyrolysis, like precise temperature control and process efficiency, are areas where the right equipment makes all the difference. KINTEK specializes in high-performance lab equipment and consumables that can support your research and development in thermal conversion technologies like pyrolysis.

Whether you're optimizing processes or analyzing outputs, our solutions are designed for accuracy and reliability. Contact us today to discuss how we can support your specific laboratory needs and help you turn waste into valuable resources.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products