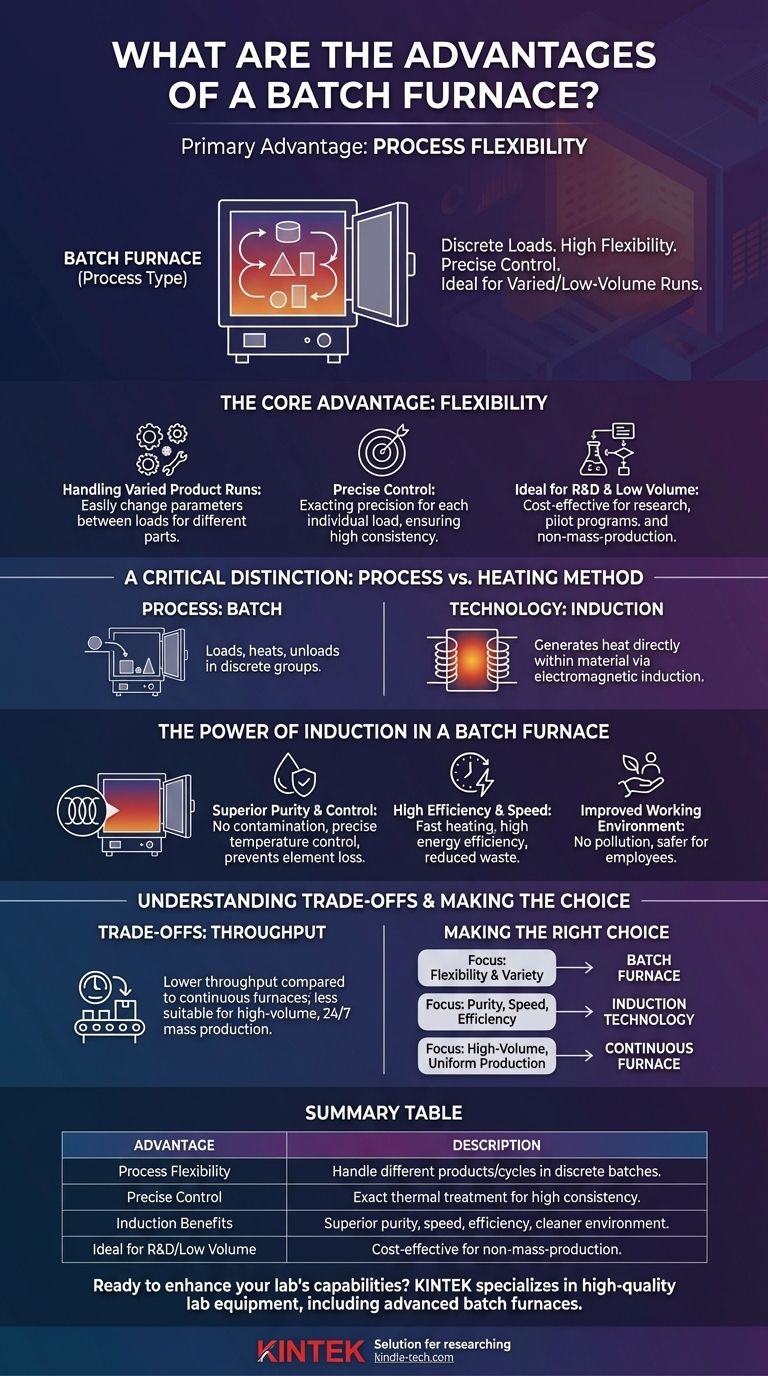

In short, the primary advantage of a batch furnace is its process flexibility. Unlike a continuous furnace that processes a constant stream of identical materials, a batch furnace is designed to heat a single, discrete load at a time. This allows you to process different products, use different heating cycles, and maintain precise control over the treatment of each individual batch.

The core decision is not just about the furnace, but about the process. A batch furnace excels at providing flexibility for varied or lower-volume production runs. When combined with a modern heating method like induction, it also delivers exceptional purity, speed, and energy efficiency.

The Core Advantage of Batch Processing: Flexibility

The defining characteristic of a batch furnace is its ability to handle materials one "batch" or "load" at a time. This operational model is the source of its key benefits.

Handling Varied Product Runs

Because each batch is a separate event, you can easily change the parameters between loads. This is ideal for job shops or manufacturing environments that produce many different parts with unique heating requirements.

Precise Control Over Individual Loads

Each batch can be tracked and controlled with exacting precision. The entire load is subjected to the same thermal cycle, ensuring high consistency and quality for that specific group of materials.

Ideal for Lower Volume and R&D

Batch furnaces are perfectly suited for research and development, pilot programs, or any production scenario that does not require massive, continuous output. Their smaller footprint and operational model make them a cost-effective choice for non-mass-production needs.

A Critical Distinction: Process vs. Heating Method

To fully understand furnace advantages, it's crucial to separate the process type (batch) from the heating method (how the heat is generated). Users often conflate these, but they are independent choices.

What Defines a Batch Furnace?

A batch furnace is defined by its process: materials are loaded, heated, and unloaded in discrete groups. The heating itself could be done by gas combustion, electrical resistance, or induction.

What Defines an Induction Furnace?

An induction furnace is defined by its heating technology. It uses electromagnetic induction to generate heat directly within the material itself. It does not require an external flame or heating element.

Why They Are Often Used Together

Modern batch furnaces frequently use induction heating because the two concepts are highly complementary. The flexibility of batch processing combined with the precision and cleanliness of induction heating creates a powerful and efficient system.

The Advantages of Induction Heating in a Batch Furnace

When a batch furnace is equipped with induction technology, it gains a powerful set of advantages that are critical for modern manufacturing.

Superior Purity and Control

Induction is a clean process. With no arc or combustion, there is no risk of contaminating the material with byproducts. This allows for extremely precise temperature control, preventing the loss of valuable and sensitive alloying elements during a melt.

High Efficiency and Speed

Heat is generated directly inside the charge material, not in the surrounding chamber. This results in very fast heating speeds and high energy efficiency, as less energy is wasted heating the furnace itself. This direct heating also ensures a small temperature difference between the material's core and its surface.

Improved Working Environment

Induction furnaces produce no pollution or combustion gases, creating a safer and cleaner environment for workers. They are equipped with all-round protection features like overheating and short-circuit protection, further enhancing employee safety.

Understanding the Trade-offs

No single solution is perfect for every application. Objectivity requires acknowledging the limitations of this approach.

The Limitation of Batch Processing: Throughput

The primary trade-off of a batch process is lower throughput compared to a continuous furnace. The time spent loading, unloading, and cycling between batches makes it less suitable for high-volume, 24/7 mass production of a single product.

The Scale of Production

If your goal is to produce a massive, uniform stream of a single material, a continuous furnace is almost always a more efficient and cost-effective solution. Batch furnaces are not designed for that scale.

Making the Right Choice for Your Goal

Selecting the right furnace requires a clear understanding of your primary operational driver.

- If your primary focus is flexibility and product variety: A batch furnace is the ideal process model for your needs.

- If your primary focus is material purity, speed, and energy efficiency: Induction is the superior heating technology to specify for your furnace.

- If your primary focus is high-volume, uniform production: A continuous furnace, rather than a batch model, is likely the more appropriate choice.

Ultimately, understanding the distinct roles of the process and the technology empowers you to select a system that precisely matches your manufacturing goals.

Summary Table:

| Advantage | Description |

|---|---|

| Process Flexibility | Handle different products and heating cycles in discrete batches, ideal for varied production runs. |

| Precise Control | Each batch receives exact thermal treatment, ensuring high consistency and quality. |

| Induction Heating Benefits | When combined with induction, offers superior purity, speed, energy efficiency, and a cleaner work environment. |

| Ideal for R&D/Low Volume | Cost-effective solution for research, pilot programs, and non-mass-production needs. |

Ready to enhance your lab's capabilities with a flexible and efficient batch furnace?

At KINTEK, we specialize in providing high-quality lab equipment, including advanced batch furnaces tailored to your specific needs. Whether you require the flexibility of batch processing for varied product runs or the superior performance of induction heating for purity and efficiency, our solutions are designed to meet your laboratory's unique challenges.

Contact us today to discuss how a KINTEK batch furnace can optimize your processes and deliver precise, reliable results for your research or production goals.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is graphite a conductive metal? Discover Why This Non-Metal Powers Modern Technology

- How is powder metallurgy different from other manufacturing processes? Build Parts with Minimal Waste

- What safety precautions should you use when working with a heat source? Essential Guidelines for a Safe Lab Environment

- What are the applications of optical thin film? Unlocking Precision Light Control

- What is the pulse magnetron sputtering method? Achieve Arc-Free Deposition of Insulating Films

- What is the function of a backpressure controller in electrocatalyst stability? Ensure Long-Term Data Integrity.

- What is a lab oven used for? A Guide to Precise Heating, Sterilization & Drying

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety