The primary advantage of press forging is its ability to deliver a slow, controlled, and uniform deformation throughout the entire volume of the workpiece. Unlike the sharp, superficial impacts of a hammer, the continuous pressure of a forge press works the metal from its surface to its core. This results in a more refined grain structure, superior mechanical properties, and greater dimensional accuracy, especially for large and complex components.

While hammer forging shapes metal with rapid surface impacts, press forging uses slow, continuous pressure to shape the entire component. This fundamental difference makes press forging the superior choice for large parts and high-performance alloys where internal structural integrity is the critical factor.

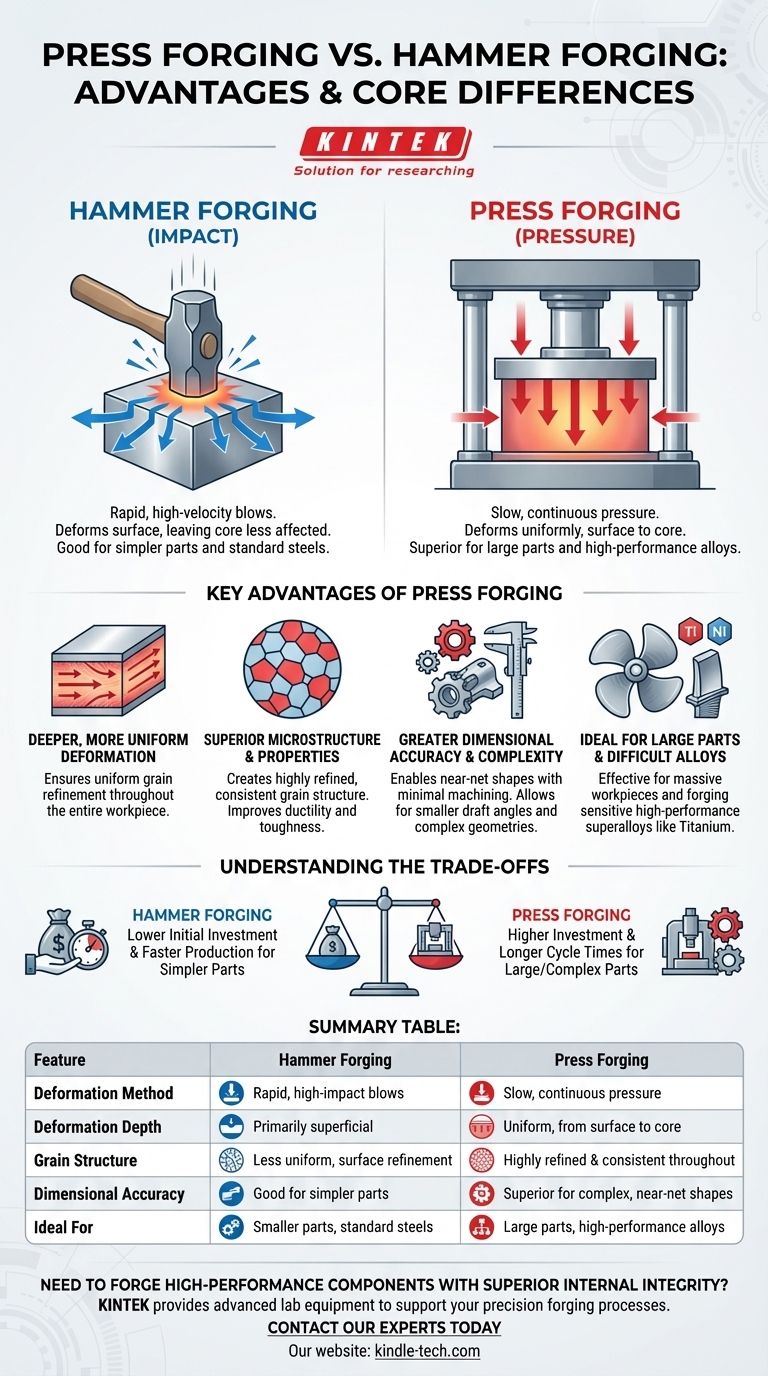

The Core Difference: Impact vs. Pressure

The choice between hammer and press forging comes down to how energy is transferred to the workpiece. This single difference dictates the outcome of the entire process.

Hammer Forging: A Series of Sharp Blows

A forging hammer acts like a sprinter, delivering its energy in a short, high-velocity burst. The hammer strikes the workpiece, and its kinetic energy is transferred almost instantly.

This rapid impact primarily deforms the surface of the metal. The contact time is too short for the force and heat to fully penetrate, often leaving the core of the workpiece less affected.

Press Forging: A Single, Continuous Squeeze

A forging press is like a powerlifter, applying immense force in a slow, controlled manner. It squeezes the metal into shape rather than striking it.

This prolonged contact allows the pressure to penetrate deep into the material, deforming the workpiece uniformly through its entire cross-section.

Key Advantages of Press Forging

The "squeeze vs. strike" distinction gives press forging several distinct technical advantages for specific applications.

Deeper, More Uniform Deformation

Because the press applies force slowly, it overcomes the material's internal resistance uniformly. This ensures that the grain structure at the center of the workpiece is refined just as much as the structure at the surface.

This is crucial for large components where inconsistent properties between the core and the surface could lead to failure under stress.

Superior Microstructure and Mechanical Properties

The uniform deformation achieved through press forging creates a highly refined and consistent grain structure. This leads directly to improved mechanical properties like ductility and toughness.

The process avoids the localized stress and potential for micro-cracks that can sometimes occur with the high-impact nature of hammer forging, especially in sensitive alloys.

Greater Dimensional Accuracy and Complexity

Press forging allows for exceptional control. This precision enables the creation of near-net shapes—parts that are very close to their final dimensions and require minimal subsequent machining.

It also allows for designs with smaller draft angles (the taper on the sides of the part), enabling more complex geometries that would be impossible to achieve with a hammer.

Ideal for Large Parts and Difficult Alloys

For very large components, a hammer's impact may not have enough energy to deform the core. A press, however, can apply sufficient force over time to shape massive workpieces.

Furthermore, high-performance materials like titanium and nickel-based superalloys respond poorly to rapid impacts and can crack. The slow, controlled deformation of a press is essential for forging these advanced materials successfully.

Understanding the Trade-offs

Press forging is not universally superior. The optimal choice depends entirely on the component's size, material, and production volume. Hammer forging remains a highly effective process for many applications.

Cost and Initial Investment

Forging presses, especially large hydraulic ones, represent a significantly higher capital investment than forging hammers. This makes hammer forging a more accessible entry point for many operations.

Production Speed for Simpler Parts

For smaller, less complex components, a hammer's rapid succession of blows can result in a faster cycle time per part compared to the slow squeeze of a press.

Material Suitability

Some materials respond well to the high strain rate of hammer forging. For simpler carbon and alloy steels in smaller configurations, hammering is an extremely efficient and effective method for shaping and grain refinement.

Making the Right Choice for Your Component

Your final decision should be driven by the specific requirements of the finished part, not by a belief that one process is simply "better" than the other.

- If your primary focus is ultimate mechanical performance and internal integrity: Choose press forging for its uniform grain refinement, especially for critical aerospace, power generation, or industrial parts.

- If your primary focus is producing large, complex, near-net shapes: Press forging offers superior dimensional control and the ability to form intricate geometries with less machining.

- If your primary focus is working with high-performance superalloys or titanium: The slow, controlled deformation of press forging is essential to prevent cracking and ensure metallurgical quality.

- If your primary focus is cost-effective production of smaller, simpler parts from standard steels: Hammer forging provides faster cycle times and requires a lower initial capital investment.

Ultimately, selecting the right process requires a clear understanding of your material, component geometry, and final performance requirements.

Summary Table:

| Feature | Hammer Forging | Press Forging |

|---|---|---|

| Deformation Method | Rapid, high-impact blows | Slow, continuous pressure |

| Deformation Depth | Primarily superficial | Uniform, from surface to core |

| Grain Structure | Less uniform, surface refinement | Highly refined and consistent throughout |

| Dimensional Accuracy | Good for simpler parts | Superior for complex, near-net shapes |

| Ideal For | Smaller parts, standard steels | Large parts, high-performance alloys (titanium, superalloys) |

Need to forge high-performance components with superior internal integrity?

At KINTEK, we specialize in providing advanced lab equipment and consumables that support the development and quality control of precision forging processes. Whether you are working with titanium, superalloys, or other advanced materials, our solutions help ensure your materials meet the highest standards.

Contact our experts today to discuss how KINTEK can support your laboratory's needs in materials testing and analysis.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Double Plate Heating Press Mold for Lab

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- What is the ratio of KBr and sample in IR? Achieve Perfect Sample Concentration for Clear IR Spectra

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation