At its core, Chemical Vapor Deposition (CVD) is a highly versatile manufacturing process used to create exceptionally high-purity and high-performance thin films and coatings. Its primary applications are in the electronics industry for fabricating semiconductor devices, on cutting tools to create wear-resistant surfaces, and in the energy sector for producing thin-film solar cells.

The true value of CVD lies not just in applying a coating, but in its ability to grow a new, dense, and perfectly uniform solid layer on a substrate, atom by atom. This makes it the essential choice for applications where the quality and conformity of the film are absolutely critical to performance.

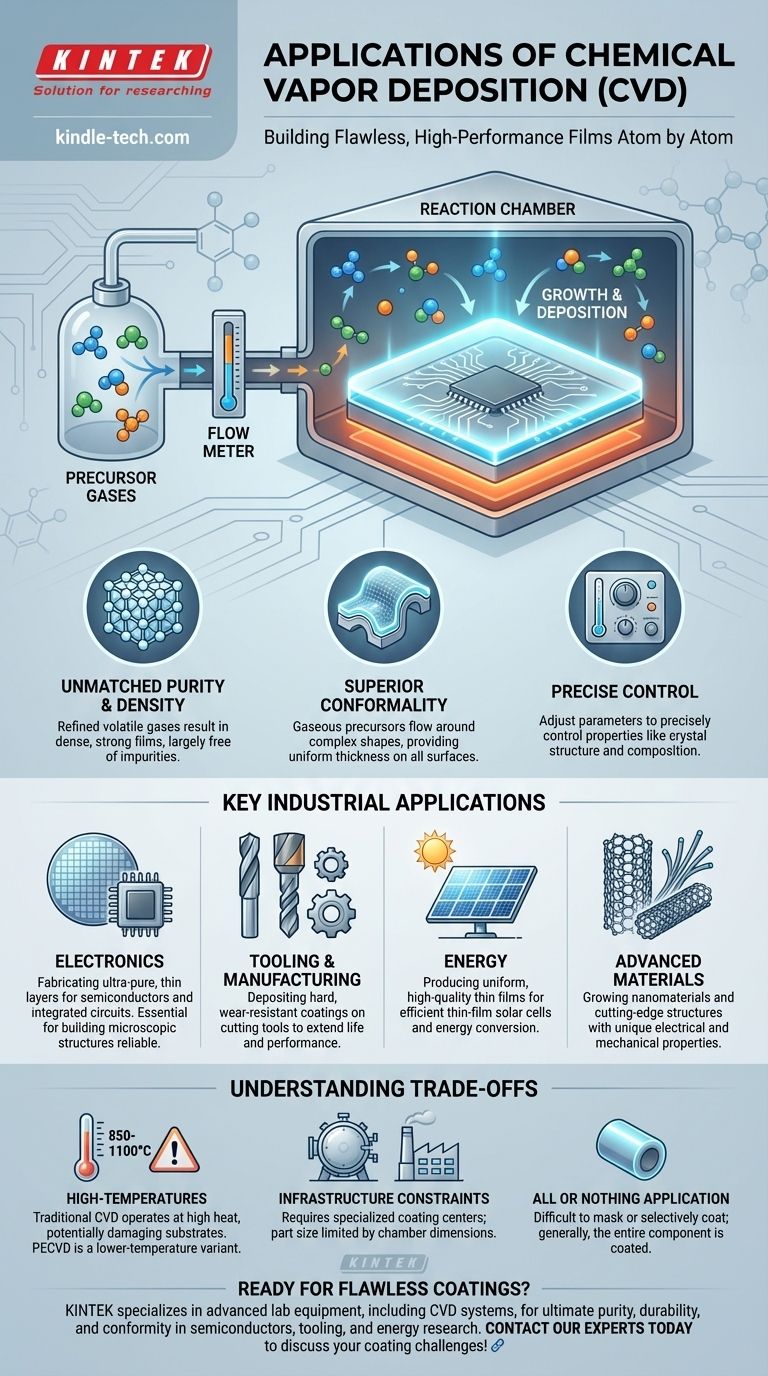

The Principle: Building Materials from Gas

Chemical Vapor Deposition is fundamentally different from painting or spraying. It involves introducing precursor gases into a reaction chamber where they decompose and react on the surface of a heated substrate, meticulously building the desired film.

Unmatched Purity and Density

Because the source materials are volatile gases, they can be refined to incredibly high levels of purity. This process results in solid films that are dense, strong, and largely free of the impurities that can plague other coating methods.

Superior Conformality

The gaseous precursors flow around the substrate, depositing a film of uniform thickness on all surfaces, including complex shapes and internal cavities. This "wrap-around" capability is a significant advantage over line-of-sight deposition techniques.

Precise Control Over Properties

By carefully adjusting deposition parameters like temperature, pressure, and gas composition, engineers can precisely control the final film's characteristics. This includes its crystal structure, chemical composition, and grain size.

Key Industrial Applications Explained

The unique characteristics of CVD make it indispensable in several high-technology fields. Its application is dictated by the need for performance that less advanced methods cannot achieve.

The Foundation of Modern Electronics

The fabrication of integrated circuits involves depositing dozens of ultra-thin layers of conducting, semiconducting, and insulating materials. CVD provides the purity and precise thickness control required to build these microscopic structures reliably.

Enhancing Durability and Performance

Hard ceramic coatings are deposited via CVD onto industrial cutting tools, drills, and machine components. These dense, low-stress films dramatically increase resistance to wear, corrosion, and high temperatures, extending the life and performance of the tools.

Powering a Sustainable Future

CVD is used to deposit the thin layers of photovoltaic materials that form the active region of thin-film solar cells. The high quality and uniformity of these films are essential for efficiently converting sunlight into electricity.

Advanced Materials and Nanotechnology

The process is also critical in cutting-edge research and manufacturing. It is a preferred method for growing advanced materials like carbon nanotubes and various nanowires, which have unique electrical and mechanical properties.

Understanding the Practical Trade-offs

Despite its advantages, CVD is not a universal solution. Its operational requirements introduce specific limitations that must be considered.

High-Temperature Requirements

Traditional CVD processes operate at very high temperatures, often between 850-1100°C. This heat can damage or warp many substrate materials, limiting its use. However, variants like Plasma-Enhanced CVD (PECVD) can operate at much lower temperatures to overcome this.

Process and Infrastructure Constraints

CVD is not a portable process; parts must be sent to a specialized coating center. The size of the components that can be coated is limited by the dimensions of the vacuum chamber, and complex assemblies must be broken down into individual parts before treatment.

The "All or Nothing" Application

The nature of the process makes it very difficult to mask or selectively coat only a portion of a surface. Generally, the entire component exposed within the chamber will be coated.

Making the Right Choice for Your Goal

Selecting the right coating technology depends entirely on your end goal. CVD excels where ultimate performance is the primary driver.

- If your primary focus is maximum purity and film quality: CVD is the superior choice for applications like semiconductors or high-performance optics where material integrity is non-negotiable.

- If your primary focus is enhancing durability on complex shapes: CVD's excellent "wrap-around" capability makes it ideal for uniformly coating intricate components like engine parts or specialized tools.

- If your primary focus is coating temperature-sensitive materials: Standard CVD is unsuitable; you must explore lower-temperature variants like Plasma-Enhanced CVD (PECVD) to avoid damaging your substrate.

Ultimately, Chemical Vapor Deposition is the definitive technology for creating flawless, high-performance films that become an integral part of the underlying material.

Summary Table:

| Application Area | Key Use of CVD |

|---|---|

| Electronics | Fabricating ultra-pure, thin layers for semiconductors and integrated circuits. |

| Tooling & Manufacturing | Depositing hard, wear-resistant coatings on cutting tools and components. |

| Energy | Producing uniform, high-quality thin films for solar cells. |

| Advanced Materials | Growing nanomaterials like carbon nanotubes and nanowires. |

Ready to integrate flawless, high-performance coatings into your products?

KINTEK specializes in advanced lab equipment, including Chemical Vapor Deposition systems, to help you achieve the ultimate in film purity, durability, and conformity for your most critical applications in semiconductors, tooling, and energy research.

Contact our experts today to discuss how CVD technology can solve your specific coating challenges!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate