While brazing creates strong, clean joints, its primary disadvantages stem from the strict process controls required. These include the absolute necessity for clean surfaces, the risk of heat damage to the base materials, and the inherent strength limitations compared to welding. Certain materials, like those with stable oxide layers or significant thermal expansion differences, introduce further complexity.

The core challenge of brazing isn't a single flaw, but a series of demanding prerequisites. Success hinges on precise control over material preparation, temperature, and joint design, making it less forgiving than other joining methods in certain scenarios.

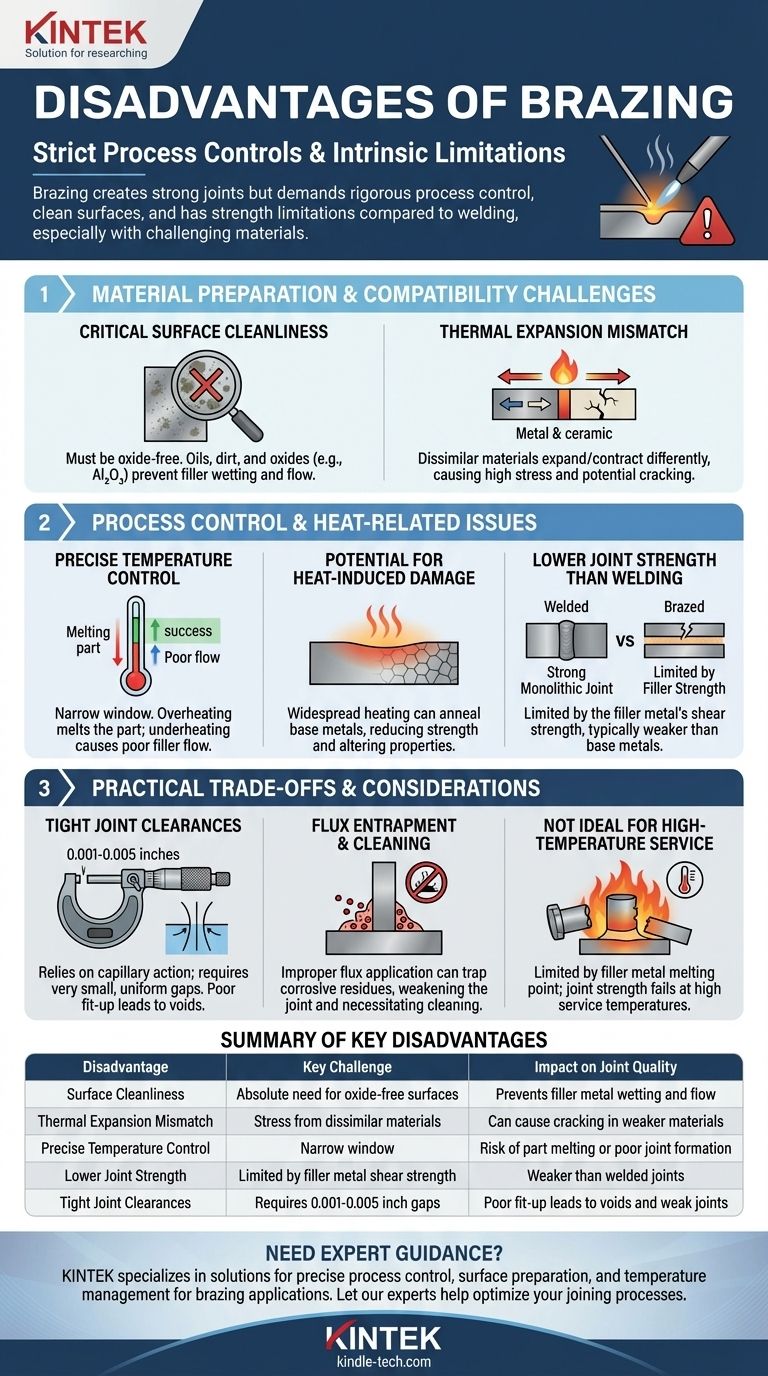

The Challenge of Material Preparation and Compatibility

Brazing relies on the intimate contact between a liquid filler metal and a solid base metal. Anything that interferes with this interaction will compromise the joint's integrity.

The Critical Need for Surface Cleanliness

All surfaces to be brazed must be exceptionally clean. Oils, dirt, and especially oxides will prevent the filler metal from "wetting" and flowing into the joint via capillary action.

Materials like aluminum are particularly challenging because they form a tough, stable oxide layer (Al₂O₃) almost instantly. This layer must be removed with chemical fluxes or mechanical means just before brazing, and its reformation must be prevented during the heating process.

Managing Thermal Expansion Mismatch

When joining dissimilar materials, such as a ceramic and a metal, their different rates of thermal expansion can be a significant problem. As the assembly is heated and cooled, one material will expand and contract more than the other.

This differential movement induces high stress at the joint interface. Without careful joint design to accommodate this stress, the weaker material (often the ceramic) can easily crack.

Process Control and Heat-Related Issues

The brazing process itself introduces several potential points of failure if not managed with precision.

Precise Temperature Control is Non-Negotiable

Brazing operates in a narrow temperature window. The assembly must be hot enough to melt the filler metal but remain below the melting point of the base metals.

For some materials, like certain aluminum alloys, the melting point of the filler metal is very close to that of the base metal. Even minor temperature overshoots can lead to the part melting, while underheating results in poor filler flow and a weak joint.

Potential for Heat-Induced Damage

Unlike localized welding, brazing typically requires heating the entire assembly to the flow temperature of the filler metal. This widespread heating can negatively alter the properties of the base metals.

For example, heat-treated or work-hardened metals can be softened (annealed) by the brazing cycle, reducing their strength. This must be accounted for in the design phase.

Lower Joint Strength than Welding

A brazed joint's strength is limited by the shear strength of the filler metal, which is almost always lower than that of the base metals being joined.

Welding, in contrast, fuses the base metals together, often with a filler of similar composition. This creates a continuous, monolithic joint that is typically as strong as or stronger than the original materials.

Understanding the Practical Trade-offs

Beyond material and process issues, several practical considerations can make brazing a less-than-ideal choice.

The Requirement for Tight Joint Clearances

Brazing depends entirely on capillary action to pull the molten filler metal into the gap between the parts. This phenomenon only works effectively with very small, uniform clearances, typically between 0.001 and 0.005 inches (0.025-0.127 mm).

Poor part fit-up or inconsistent gaps will result in voids, incomplete filler flow, and a drastically weakened joint.

Flux Entrapment and Post-Brazing Cleaning

Many brazing processes use a chemical flux to dissolve oxides and promote wetting. If not applied or heated correctly, this flux can become trapped within the finished joint.

Trapped flux creates a void, weakening the joint and often acting as a site for future corrosion. Consequently, most flux-based processes require a thorough post-brazing cleaning step to remove any corrosive residues.

Not Ideal for High-Temperature Service

The maximum service temperature for a brazed component is always limited by the melting point of the filler metal. The joint will lose strength rapidly as it approaches this temperature, making brazing unsuitable for applications in very high-heat environments.

Making the Right Choice for Your Goal

Brazing remains an excellent choice when its specific requirements can be met and its limitations are accounted for in the design.

- If your primary focus is joining dissimilar materials: Brazing is often superior to welding, but you must carefully design the joint to manage stresses from thermal expansion.

- If your primary focus is avoiding distortion: Brazing's lower temperatures and uniform heating cause less distortion than welding, but be aware that the heat can still soften the base metals.

- If your primary focus is joint strength: Welding generally produces stronger joints, as the strength is not limited by a weaker filler material.

Understanding these disadvantages is the key to successfully applying brazing where its unique strengths can provide the most value.

Summary Table:

| Disadvantage | Key Challenge | Impact on Joint Quality |

|---|---|---|

| Surface Cleanliness | Absolute need for oxide-free surfaces | Prevents filler metal wetting and flow |

| Thermal Expansion Mismatch | Stress from dissimilar materials | Can cause cracking in weaker materials |

| Precise Temperature Control | Narrow window between filler melt and base metal melt | Risk of part melting or poor joint formation |

| Lower Joint Strength | Limited by filler metal shear strength | Weaker than welded joints |

| Tight Joint Clearances | Requires 0.001-0.005 inch gaps for capillary action | Poor fit-up leads to voids and weak joints |

Need expert guidance for your material joining challenges? At KINTEK, we specialize in laboratory equipment and consumables that help you achieve precise process control for applications like brazing. Our solutions ensure proper surface preparation, temperature management, and joint integrity for your specific materials. Let our experts help you optimize your joining processes—contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Boron Nitride (BN) Ceramic Rod for High Temperature Applications

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Boron Nitride (BN) Ceramic Tube

People Also Ask

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy