The most common examples of PVD coatings are thin, hard films like Titanium Nitride (TiN) applied to products ranging from industrial drill bits to consumer goods like kitchen faucets and jewelry. These applications leverage the coating's ability to dramatically improve a product's surface properties, including its hardness, durability, and resistance to wear and corrosion.

Physical Vapor Deposition (PVD) is not a single type of coating, but rather a versatile vacuum deposition process used to apply a wide variety of high-performance thin films onto a substrate. The specific material vaporized during the process, not the process itself, defines the coating and its final properties.

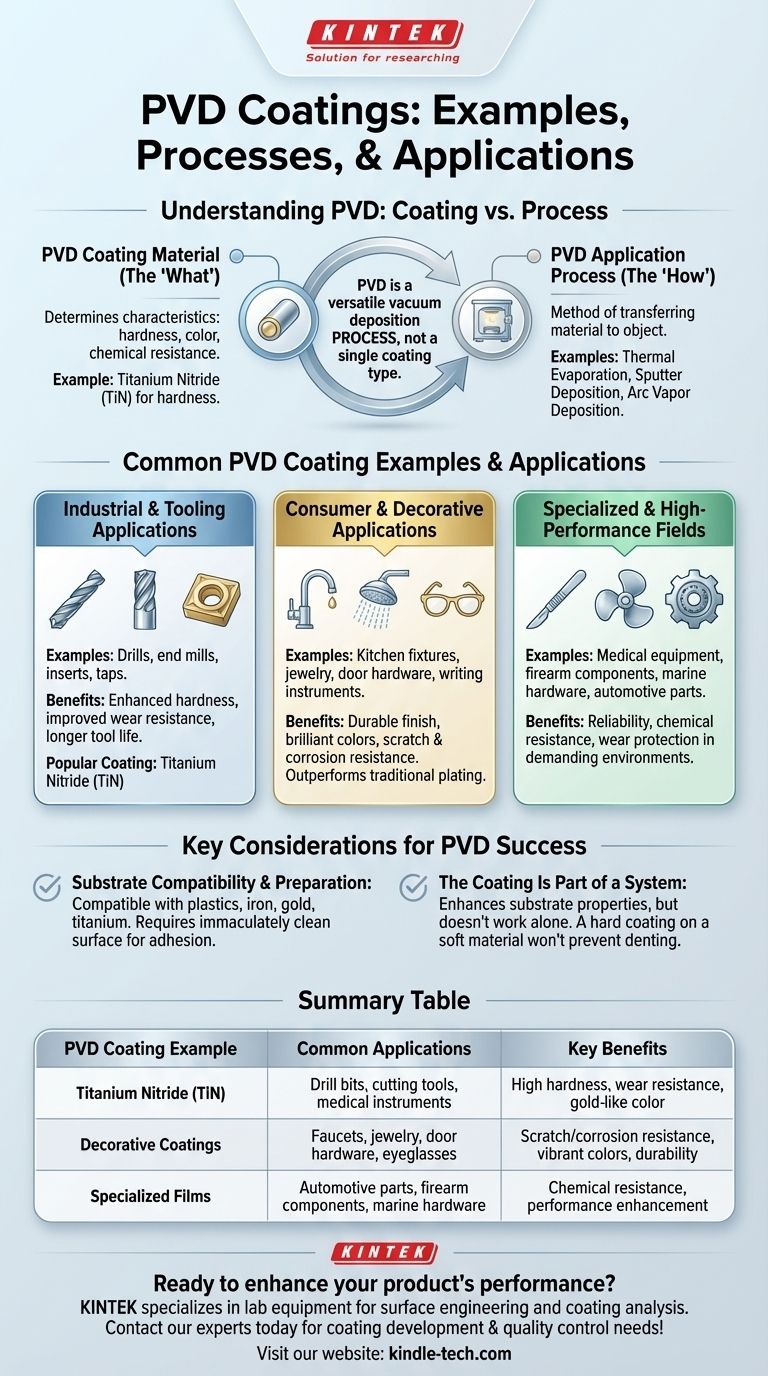

Understanding PVD: Coating vs. Process

A common point of confusion is the difference between the PVD coating material and the PVD application process. Understanding this distinction is the first step to truly grasping the technology.

Common PVD Coating Materials (The "What")

The specific material used for the coating determines its characteristics, such as hardness, color, and chemical resistance.

One of the most widely recognized examples is Titanium Nitride (TiN). As a coating, TiN is known for its exceptional hardness and wear resistance, which is why it's a popular choice for industrial cutting tools.

The properties of any PVD coating are a direct result of the material being deposited and how it interacts with the base material, or substrate.

Common PVD Application Processes (The "How")

The PVD process is how the coating material is transferred to the object. The three primary methods are:

- Thermal Evaporation: The coating material is heated in a vacuum until it evaporates, after which it condenses onto the substrate as a thin film.

- Sputter Deposition: High-energy ions bombard the coating material (the "target"), knocking off atoms that then deposit onto the substrate.

- Arc Vapor Deposition: A high-current, low-voltage arc is used to vaporize the coating material, creating a highly ionized vapor that forms a very dense coating on the substrate.

Where PVD Coatings Are Used in Practice

The benefits of PVD coatings—durability, resistance, and aesthetic flexibility—make them suitable for an exceptionally wide range of applications.

Industrial and Tooling Applications

In manufacturing and machining, performance is paramount. PVD coatings extend the life and improve the efficiency of critical components.

Examples include drills, end mills, inserts, and taps. Applying a PVD coating to these tools provides enhanced hardness and significantly improved wear resistance, leading to longer tool life and better performance.

Consumer and Decorative Applications

For consumer products, PVD offers a finish that is far more durable than traditional plating. It provides brilliant colors while protecting against scratches and corrosion.

Common examples are kitchen and bath fixtures (faucets, showerheads), door hardware, jewelry, eyeglass frames, and writing instruments. The coating ensures these high-touch items maintain their appearance for years.

Specialized and High-Performance Fields

In sectors where reliability is non-negotiable, PVD coatings provide a crucial layer of protection and performance enhancement.

This includes medical equipment, firearm components, marine hardware, and automotive parts. The coating's ability to resist chemicals and wear makes it ideal for these demanding environments.

Understanding the Key Considerations

While powerful, PVD technology is not a universal solution. The effectiveness of the coating is intrinsically linked to the material it is applied to.

Substrate Compatibility and Preparation

PVD is compatible with a wide array of materials, including plastics, iron, gold, and titanium. However, the surface of the object must be immaculately clean for the coating to adhere properly.

The final properties of the coated part are a combination of the substrate and the film. The coating enhances the surface, but the underlying material provides the structural integrity.

The Coating Is Part of a System

The coating does not work in isolation. For instance, a TiN coating applied to a titanium alloy (Ti-6Al-4V) can increase its endurance and fatigue limit.

This highlights that the PVD film enhances the inherent properties of the substrate. A hard coating on a soft material will not prevent the part from denting, even if the surface itself resists scratching.

Making the Right Choice for Your Goal

To determine if PVD is the right solution, consider the primary objective you need to achieve.

- If your primary focus is mechanical performance: PVD is an exceptional choice for extending the life of tools and wear parts by increasing surface hardness and reducing friction.

- If your primary focus is durability and aesthetics: PVD offers a robust and colorful finish for consumer goods that dramatically outperforms traditional plating in resisting scratches and corrosion.

- If your primary focus is environmental resistance: For components exposed to chemicals or harsh conditions, PVD provides a stable, inert barrier that protects the underlying material.

Ultimately, PVD technology provides a powerful way to engineer the surface of an object to give it properties it otherwise wouldn't possess.

Summary Table:

| PVD Coating Example | Common Applications | Key Benefits |

|---|---|---|

| Titanium Nitride (TiN) | Drill bits, cutting tools, medical instruments | High hardness, wear resistance, gold-like color |

| Decorative Coatings | Faucets, jewelry, door hardware, eyeglass frames | Scratch/corrosion resistance, vibrant colors, durability |

| Specialized Films | Automotive parts, firearm components, marine hardware | Chemical resistance, performance enhancement in harsh environments |

Ready to enhance your product's performance and durability with a PVD coating? KINTEK specializes in lab equipment and consumables for surface engineering and coating analysis. Our solutions help you select, test, and apply the right PVD coating for your specific substrate and performance goals. Contact our experts today to discuss how we can support your laboratory's coating development and quality control needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer