While induction heating is a remarkably efficient and precise technology, its primary limitations are its strict dependency on electrically conductive materials, the significant initial capital investment for equipment, and the engineering complexity required to effectively heat parts with intricate geometries. It is not a universal solution and is unsuitable for materials like plastics, ceramics, or wood.

The core challenge of implementing induction heating is not in its performance, but in its applicability. Its unparalleled speed and control are only accessible if your material, part geometry, and production volume can justify the specialized and often costly equipment required.

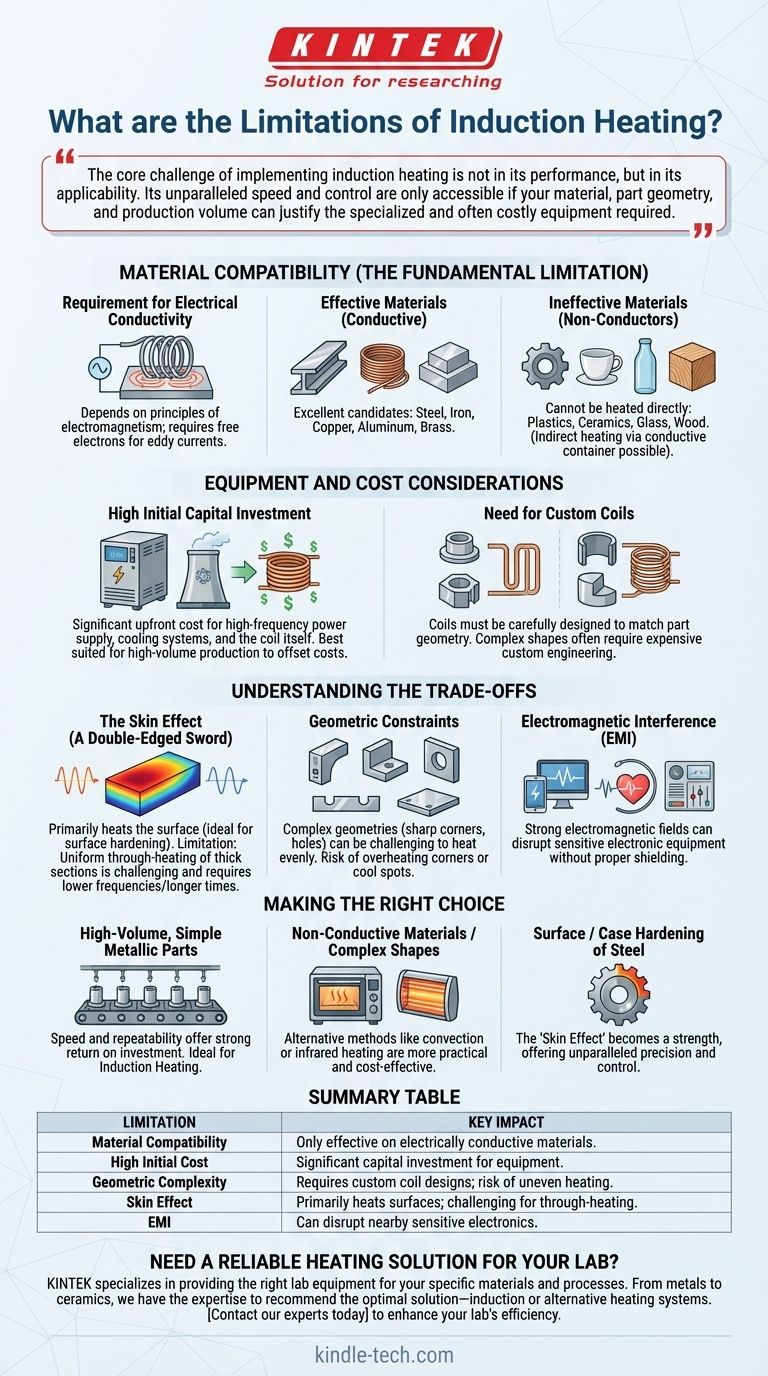

The Fundamental Limitation: Material Compatibility

Induction heating works by inducing an electrical current directly within the material itself. This core principle dictates what can and cannot be heated effectively.

The Requirement for Electrical Conductivity

Induction heating relies on the principles of electromagnetism. An alternating current in a coil creates a magnetic field, which in turn induces eddy currents in a conductive workpiece, generating heat.

This means the process is fundamentally limited to materials that conduct electricity. Metals such as steel, iron, copper, aluminum, and brass are excellent candidates.

Ineffectiveness with Non-conductors

Materials that do not conduct electricity—such as plastics, glass, ceramics, and wood—cannot be heated directly by induction. They do not have the free electrons necessary for eddy currents to form.

While a non-conductive material can sometimes be heated indirectly by placing it in a conductive container (a graphite crucible, for example), this is a different process that sacrifices many of the direct heating benefits.

Equipment and Cost Considerations

The power and precision of induction come at a price, both in terms of initial cost and operational complexity.

High Initial Capital Investment

The required equipment—including a high-frequency power supply, cooling systems, and the induction coil itself—represents a significant upfront cost compared to conventional ovens or furnaces.

This makes induction heating best suited for high-volume, repetitive production environments where the efficiency gains can offset the initial investment over time.

The Need for Custom Coils

The induction coil (or inductor) must be carefully designed to match the geometry of the part being heated. An improperly designed coil will result in uneven heating, hotspots, or inefficient energy transfer.

For parts with complex shapes, a custom-engineered coil is almost always necessary, adding to the engineering time and overall cost of the system.

Understanding the Trade-offs

Several operational characteristics of induction heating can be either a key advantage or a significant limitation, depending entirely on the application's goal.

The Skin Effect: A Double-Edged Sword

Induction heating primarily heats the surface of a conductive part, a phenomenon known as the "skin effect." The frequency of the alternating current determines the depth of this heating.

This is a powerful advantage for applications like surface hardening, where you want a hard outer case and a ductile core. However, it becomes a limitation when trying to heat a very thick metal part uniformly through its entire cross-section, which requires lower frequencies and longer heating times.

Geometric Constraints

The efficiency of the magnetic field coupling is highly dependent on the distance and alignment between the coil and the workpiece.

Complex geometries with sharp corners, holes, or varying thicknesses can be challenging to heat evenly. Corners can overheat while recessed areas remain too cool, potentially leading to material stress or warping.

Potential for Electromagnetic Interference (EMI)

High-power induction systems generate strong electromagnetic fields. Without proper shielding and installation, these fields can interfere with sensitive electronic equipment, control systems, or medical devices in the surrounding area.

Making the Right Choice for Your Goal

Your decision to use induction heating must be based on a clear understanding of its ideal use cases and its inherent constraints.

- If your primary focus is high-volume production of simple, metallic parts: The speed and repeatability of induction heating will likely provide a strong return on the initial investment.

- If your primary focus is heating non-conductive materials or complex shapes: You will likely find that alternative methods, like convection or infrared heating, are more practical and cost-effective.

- If your primary focus is surface hardening or case hardening of steel components: The "limitation" of the skin effect becomes the technology's greatest strength, offering unparalleled precision and control.

Ultimately, choosing the right heating technology requires matching its specific capabilities to your precise industrial or manufacturing goal.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Material Compatibility | Only effective on electrically conductive materials (e.g., metals); unsuitable for plastics, ceramics, wood. |

| High Initial Cost | Significant capital investment for power supplies, cooling systems, and custom coils. |

| Geometric Complexity | Requires custom coil designs for intricate parts; risk of uneven heating on complex shapes. |

| Skin Effect | Primarily heats surfaces; challenging for uniform through-heating of thick sections. |

| Electromagnetic Interference (EMI) | Can disrupt nearby sensitive electronics without proper shielding. |

Need a Reliable Heating Solution for Your Lab?

Induction heating is powerful, but it's not the only option. KINTEK specializes in providing the right lab equipment for your specific materials and processes. Whether you're working with metals, ceramics, or complex geometries, we have the expertise to recommend the optimal solution—from induction furnaces to alternative heating systems.

Let us help you enhance your lab's efficiency and precision. Contact our experts today to discuss your application and discover how KINTEK's lab equipment and consumables can meet your unique needs.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- What are the advantages of using a Vacuum Hot-Pressing Furnace for Ti-6Al-4V? Achieve Forged-Like Strength & Purity

- Why is a small pressure applied during SiCf/TB8 debinding? Master Fiber Alignment in Vacuum Hot Pressing