At its core, the Hot Isostatic Pressing (HIP) process is governed by three primary parameters: temperature, pressure, and time. These variables are applied within a controlled, inert atmosphere to eliminate internal porosity and improve the mechanical properties of a component. The entire cycle is precisely managed to achieve full material densification without distorting the part's final shape.

The crucial insight is that HIP is not a simple heating and squeezing operation. It is a sophisticated thermodynamic cycle where temperature makes the material malleable, and high-pressure inert gas acts as a uniform force to collapse internal voids and create a fully dense, metallurgically superior component.

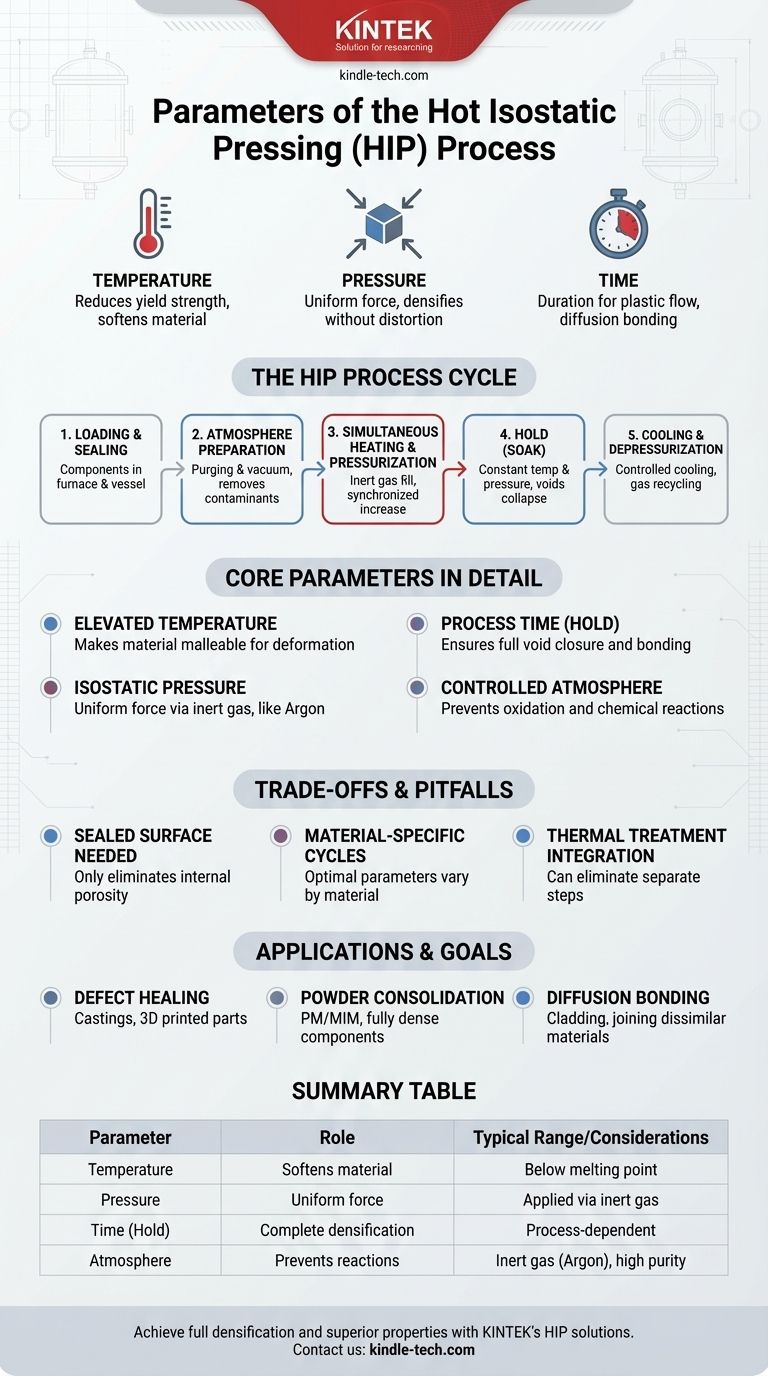

Deconstructing the HIP Process Cycle

The parameters of HIP are applied within a distinct, multi-stage process. Understanding this cycle provides the context for how temperature, pressure, and time are manipulated to achieve the desired outcome.

Step 1: Loading and Sealing

Components are loaded into a furnace, which is then placed inside a high-pressure containment vessel. The vessel is sealed to create a closed system.

Step 2: Atmosphere Preparation

Before heating, the chamber undergoes purging and vacuum cycles. This critical step removes moisture, air, and other contaminants that could react with the material at high temperatures.

Step 3: Simultaneous Heating and Pressurization

The chamber is filled with a high-purity inert gas, most commonly argon, to prevent chemical reactions. The temperature and pressure are then raised simultaneously according to a carefully programmed profile specific to the material and application.

Step 4: Hold (Soak)

Once the target temperature and pressure are reached, they are held constant for a specific duration. It is during this "hold" or "soak" time that the material's internal voids and defects collapse and weld shut.

Step 5: Cooling and Depressurization

After the hold time is complete, the components are cooled in a controlled manner, and the pressure is released. The inert gas is typically captured, cleaned, and recycled for future use.

The Core Parameters of HIP

Each parameter plays a distinct and critical role in the success of the process. They are not independent variables but are selected in combination to achieve a specific metallurgical result.

1. Elevated Temperature

The primary role of temperature is to reduce the material's yield strength, making it soft and malleable enough for plastic deformation to occur. The chosen temperature is typically below the material's melting point but high enough to allow internal voids to collapse under pressure.

2. Isostatic Pressure

Pressure provides the driving force for densification. The term "isostatic" is key—it means the pressure is applied uniformly from all directions by the gas medium. This ensures that the part densifies without changing its net shape.

3. Process Time (Hold/Soak Time)

Time is the third critical parameter. The component is held at the target temperature and pressure long enough for plastic flow and diffusion bonding to fully close all internal porosity. Shorter times may leave residual voids, while excessively long times can be uneconomical.

4. Controlled Atmosphere

The use of an inert gas (like argon) is a fundamental process parameter. It prevents oxidation and other chemical reactions that would degrade the material's properties at elevated temperatures, ensuring the integrity of the component's chemistry.

Understanding the Trade-offs and Pitfalls

While highly effective, the HIP process is not a universal solution. Understanding its operational constraints is essential for successful implementation.

The Need for a Sealed Surface

HIP can only eliminate internal porosity. If a defect is open to the surface, the pressurizing gas will simply fill the void, and no pressure differential will exist to close it. This is a critical consideration for parts with surface-connected cracks or porosity.

Material-Specific Cycles

There is no single set of HIP parameters. The optimal temperature, pressure, and time are highly dependent on the specific material being processed—be it a titanium alloy, a nickel superalloy, or a ceramic. Each requires a uniquely developed cycle.

Thermal Treatment Integration

A significant benefit of HIP is that its operating temperatures are often similar to those used for homogenization or solution heat treatments. The HIP cycle can sometimes be designed to eliminate the need for a separate heat treatment step, saving time and cost.

Making the Right Choice for Your Goal

The selection of HIP parameters is driven entirely by the intended application and the material system involved.

- If your primary focus is healing defects in castings or 3D printed parts: Parameters are chosen to achieve full void closure, dramatically increasing fatigue life and mechanical reliability.

- If your primary focus is consolidating metal powders (PM/MIM): The cycle is designed to transform a porous block of powder into a fully dense, solid component with properties equivalent to wrought material.

- If your primary focus is diffusion bonding or cladding: The parameters are optimized to promote atomic diffusion across the interface of two dissimilar materials, creating a robust, solid-state weld.

Ultimately, mastering the interplay between temperature, pressure, and time is the key to unlocking the full potential of the HIP process for your components.

Summary Table:

| Parameter | Role in HIP Process | Typical Range/Considerations |

|---|---|---|

| Temperature | Softens material for plastic deformation | Below melting point, material-specific |

| Isostatic Pressure | Uniform force to collapse internal voids | Applied via inert gas (e.g., Argon) |

| Time (Hold/Soak) | Duration for complete densification | Ensures full void closure, process-dependent |

| Atmosphere | Prevents oxidation and chemical reactions | Inert gas (Argon), high purity |

Ready to achieve full densification and superior mechanical properties for your components?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including Hot Isostatic Pressing solutions, to meet the precise needs of laboratories and manufacturers. Whether you are working with castings, 3D-printed parts, or powder metals, our expertise ensures optimal HIP parameters for your specific material and application.

Contact us today to discuss how our solutions can enhance your material performance and streamline your production process. Get in touch via our contact form to speak with an expert!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process