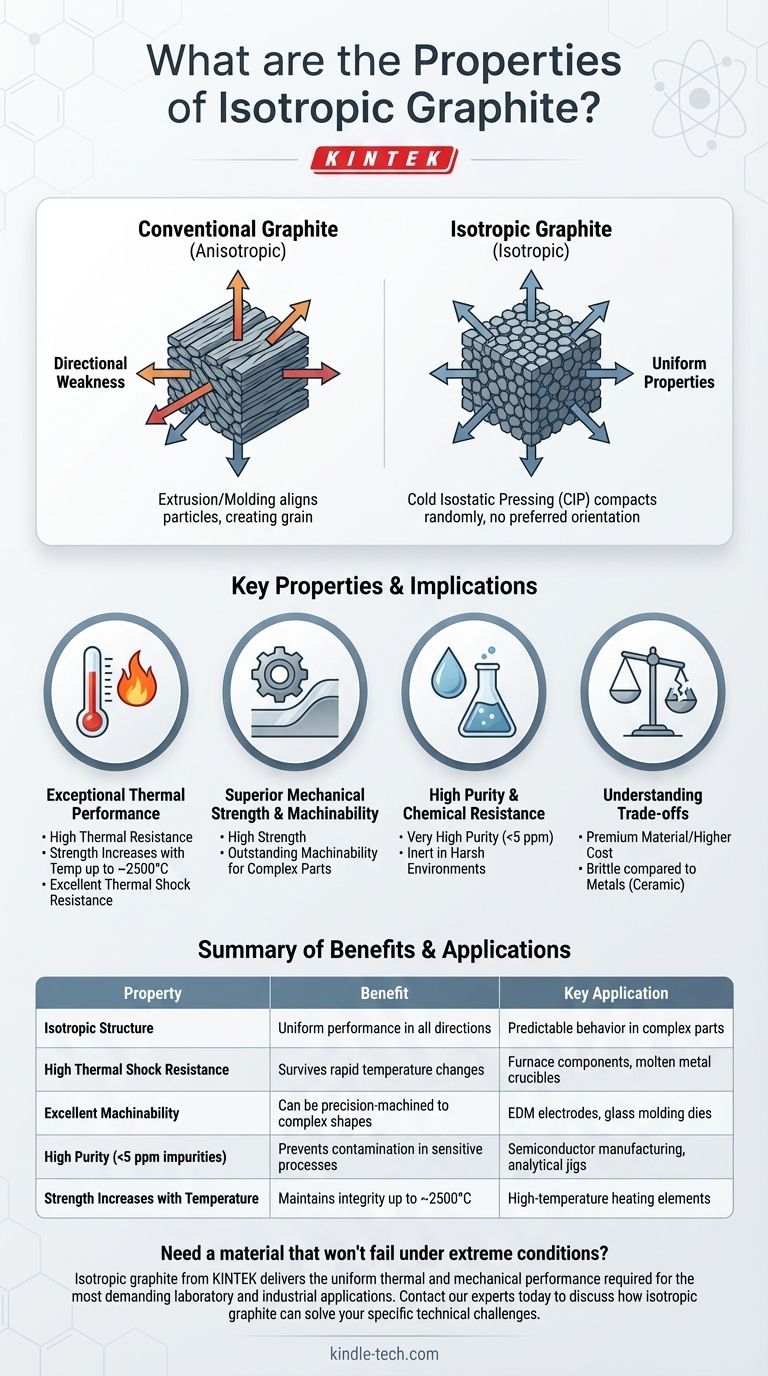

In essence, isotropic graphite is an advanced, ultra-fine-grain material defined by its uniform properties in all directions. Its key characteristics include exceptionally high thermal and chemical resistance, high strength that increases with temperature, excellent resistance to thermal shock, and the ability to be machined to precise, complex geometries. This unique combination stems from its manufacturing process, known as cold isostatic pressing (CIP).

The fundamental advantage of isotropic graphite is not just a single property, but the elimination of directional weakness. Unlike standard graphite, its uniform structure ensures predictable, high-level performance regardless of the orientation, making it a reliable choice for the most demanding applications.

What Makes This Graphite "Isotropic"?

To understand the value of isotropic graphite, you must first understand the limitations of conventional graphite, which is typically anisotropic (its properties vary depending on direction).

The Challenge with Standard Graphite

Most graphite is formed through extrusion or molding. These processes align the graphite particles in a specific direction, creating a grain.

This alignment means the material will have different thermal conductivity, electrical resistance, and mechanical strength values when measured along the grain versus against it. This can be a critical point of failure in high-stress environments.

The Isostatic Pressing Solution

Isotropic graphite is produced differently. A mixture of ultra-fine graphite particles and a binder is placed in a flexible mold and subjected to extreme, uniform hydraulic pressure from all sides in a Cold-Isostatic-Press (CIP).

This process compacts the particles randomly, with no preferred orientation. The resulting solid block, or billet, has a homogenous, non-directional, and very fine-grained internal structure.

Key Properties and Their Implications

The uniform, fine-grain structure created by isostatic pressing directly translates into a set of superior and highly predictable properties.

Exceptional Thermal Performance

Isotropic graphite excels in high-temperature environments. It offers extremely high thermal resistance and, uniquely, its mechanical strength increases with temperature up to approximately 2500°C.

Furthermore, its combination of high thermal conductivity and low thermal expansion gives it excellent resistance to thermal shock. This allows it to survive rapid temperature changes that would crack or destroy most other materials.

Superior Mechanical Strength and Machinability

Due to its ultra-fine grain and lack of directional weakness, isotropic graphite possesses high mechanical strength for a ceramic material.

This structure also allows for outstanding machinability. It can be machined into complex, intricate parts with sharp details and extremely smooth surface finishes, which is impossible with coarser, anisotropic graphite grades.

High Purity and Chemical Resistance

The manufacturing process allows for the production of isotropic graphite with very high purity, often with impurity levels below 5 parts per million (ppm). This is critical for applications like semiconductor manufacturing, where contamination can ruin entire production batches.

It also inherits graphite's natural high chemical resistance and inertness, making it suitable for use with corrosive substances and in harsh chemical environments.

Understanding the Trade-offs

While isotropic graphite offers superior performance, it is not the default choice for every application. Understanding its limitations is key to making a sound engineering decision.

Cost Considerations

Isostatic pressing is a more complex and expensive manufacturing process than simple extrusion. Consequently, isotropic graphite is a premium material with a significantly higher cost than standard graphite grades. Its use is only justified when its unique properties are truly required.

Brittleness Compared to Metals

Although it is very strong for a graphite and its strength increases with heat, it remains a ceramic material. It lacks the ductility of metals and will fracture without significant plastic deformation. It is not a suitable replacement for metal alloys in applications requiring high fracture toughness or impact resistance at room temperature.

Application Specificity

Using isotropic graphite for a simple heating element in a low-spec furnace would be overkill. It is specifically engineered for applications where the mechanical stresses, precision requirements, or thermal cycling demands exceed the capabilities of conventional fine-grain graphites.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary engineering goal.

- If your primary focus is high-temperature stability and thermal shock: Isotropic graphite is ideal for furnace components, crucibles for molten metal, and continuous casting dies due to its ability to thrive under extreme thermal cycling.

- If your primary focus is precision machining and smooth surfaces: Its uniform, fine-grain structure makes it the definitive choice for Electrical Discharge Machining (EDM) electrodes, glass molding dies, and semiconductor jigs.

- If your primary focus is material purity: Its availability in ultra-pure grades is non-negotiable for applications in the semiconductor, nuclear, and analytical industries where contamination control is paramount.

By understanding these distinct advantages, you can confidently determine if isotropic graphite is the optimal solution for your specific technical challenge.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Isotropic Structure | Uniform performance in all directions | Predictable behavior in complex parts |

| High Thermal Shock Resistance | Survives rapid temperature changes | Furnace components, molten metal crucibles |

| Excellent Machinability | Can be precision-machined to complex shapes | EDM electrodes, glass molding dies |

| High Purity (<5 ppm impurities) | Prevents contamination in sensitive processes | Semiconductor manufacturing, analytical jigs |

| Strength Increases with Temperature | Maintains integrity up to ~2500°C | High-temperature heating elements |

Need a material that won't fail under extreme conditions?

Isotropic graphite from KINTEK delivers the uniform thermal and mechanical performance required for the most demanding laboratory and industrial applications. Whether you're designing precision components for semiconductor manufacturing, high-temperature furnace parts, or complex EDM electrodes, our expertise in advanced lab materials ensures you get a solution tailored to your exact needs.

Contact our experts today to discuss how isotropic graphite can solve your specific technical challenges.

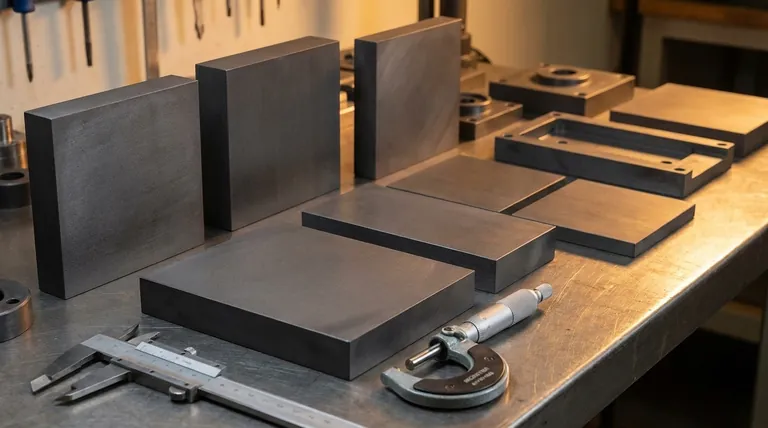

Visual Guide

Related Products

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- Is annealing the same as heat treating? Unlock the Key to Material Properties

- What is an example of cold working and hot working? Control Metal Properties for Your Project

- How to do sputtering? A Step-by-Step Guide to High-Quality Thin Film Deposition

- What is the process of calcination? A Guide to Purification & Thermal Transformation

- What maintenance should I do on my furnace? A Proactive Guide to Safety and Reliability

- Why are Crofer 22 APU supports pre-oxidized? Key Benefits for Durable Palladium Composite Membranes

- How does a laboratory electric drying oven contribute to the formation of the initial coating? Expert Insights

- What is the key difference between calcination and sintering? Understanding Purification vs. Consolidation