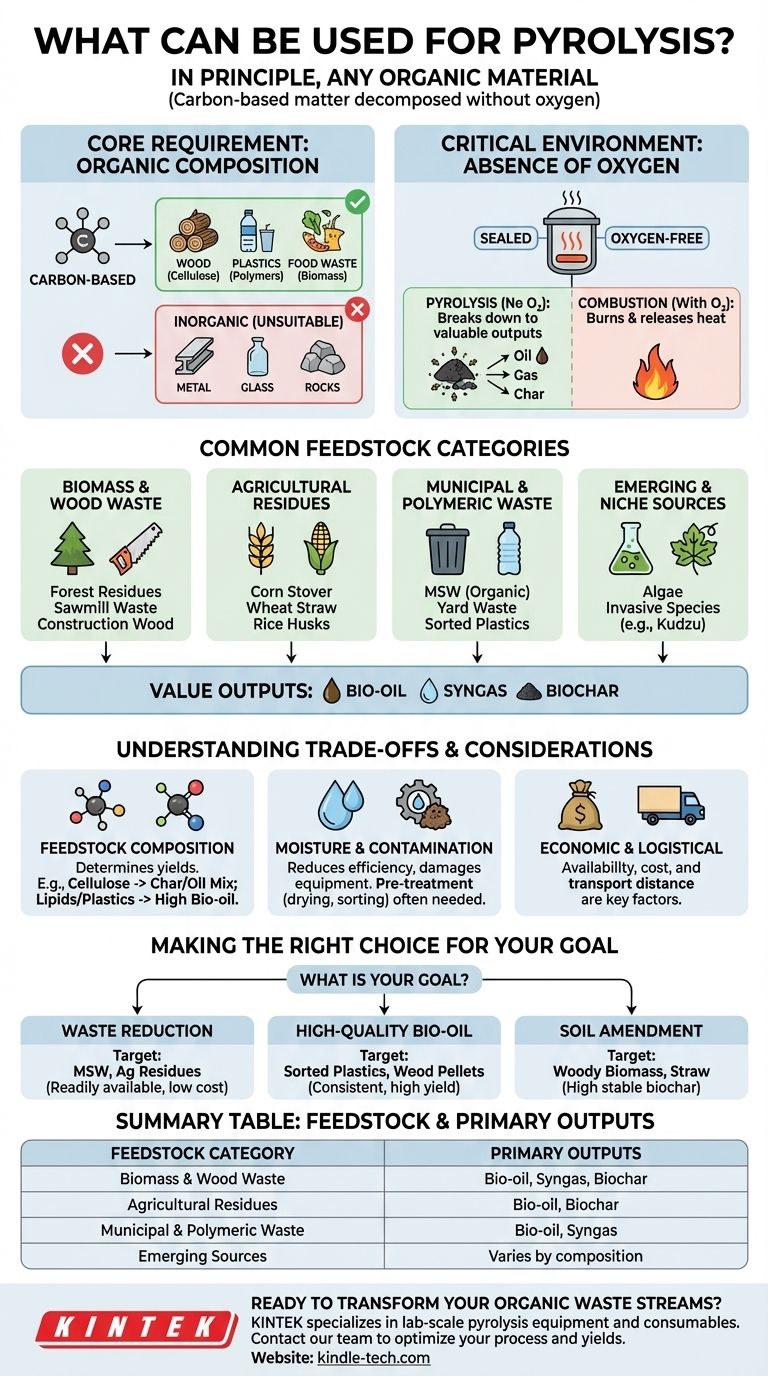

In principle, pyrolysis can be used for any organic material. This thermochemical process decomposes carbon-based matter at high temperatures in an oxygen-free environment. Common feedstocks range from biomass like wood and agricultural residues to specific types of municipal and industrial waste.

The core principle is simple: if a material is carbon-based and will decompose under heat rather than melt or vaporize, it can likely be pyrolyzed. The process is designed to prevent burning, instead breaking down complex organic polymers into valuable outputs like bio-oil, syngas, and char.

The Fundamental Principle: What Makes a Material Suitable?

To determine if a material is a candidate for pyrolysis, you must look beyond its name and assess its fundamental chemical and physical properties.

The Core Requirement: Organic Composition

Pyrolysis is a form of thermolysis (thermal decomposition) specifically for organic materials. This means the feedstock must be rich in carbon.

Materials like wood, agricultural straw, food waste, and many plastics are excellent candidates because their structure is built on carbon chains.

In contrast, inorganic materials like metals, glass, or rocks are unsuitable. They do not decompose in the same way and will either remain inert or melt, disrupting the process.

The Critical Environment: Absence of Oxygen

The process must occur in a sealed reactor with little to no oxygen. This is the key differentiator between pyrolysis and combustion (burning).

Without oxygen, the material cannot ignite. Instead of burning away and releasing its energy as heat, its chemical bonds break apart, reforming into simpler, valuable molecules.

Common Feedstock Categories for Pyrolysis

While the principle is broad, most applications focus on a few key categories of readily available organic waste streams.

Biomass and Wood Waste

This is one of the most common and well-researched feedstock categories. It includes raw materials from forestry and waste from processing.

Examples include forest residues, sawmill waste, construction wood, and dedicated energy crops.

Agricultural Residues

The agricultural sector produces vast quantities of organic waste that are ideal for pyrolysis.

Feedstocks in this category include corn stover (the stalks and leaves of corn plants), wheat straw, and rice husks.

Municipal and Polymeric Waste

Pyrolysis is a powerful tool for valorizing waste that would otherwise end up in a landfill.

This includes the organic fraction of municipal solid waste (MSW), yard waste, and certain industrial polymeric wastes, including many types of plastics.

Emerging and Niche Sources

Research is continually expanding the range of viable feedstocks.

This includes fast-growing algae, which can be cultivated for energy production, and invasive species like kudzu or phragmites, turning an ecological problem into a resource.

Understanding the Trade-offs: Not All Feedstock is Equal

Simply because a material can be pyrolyzed does not mean it is an ideal or efficient feedstock. Practical applications require careful consideration of several factors.

Impact of Feedstock Composition

The specific chemical makeup of the feedstock directly determines the final product yields.

Materials high in cellulose and hemicellulose (like wood) often produce a balanced mix of bio-oil, gas, and biochar. Feedstocks high in lipids or certain plastics may yield a much higher percentage of bio-oil.

The Challenge of Moisture and Contamination

Efficiency is highly dependent on feedstock quality. High moisture content is a significant issue, as the energy is first used to boil off water instead of decomposing the material, reducing the net energy output.

Contaminants like soil, rocks, or metal can damage equipment and reduce the quality of the final products. Pre-treatment, such as drying and sorting, is often a necessary step.

Economic and Logistical Factors

The final decision often comes down to economics. The availability and cost of the feedstock are critical.

A successful pyrolysis operation relies on a steady, low-cost supply of suitable material within a reasonable transport distance of the processing facility.

Making the Right Choice for Your Goal

The best feedstock is the one that aligns with your specific objective.

- If your primary focus is waste reduction: Prioritize readily available and low-cost streams like the organic fraction of municipal solid waste or local agricultural residues.

- If your primary focus is high-quality bio-oil production: Consider cleaner, more uniform feedstocks like sorted plastics or specific types of wood pellets that give a consistent and high oil yield.

- If your primary focus is soil amendment: Target woody biomass or straw that reliably produces a high percentage of stable biochar.

Ultimately, pyrolysis offers a powerful pathway for converting a wide array of organic "wastes" into valuable resources.

Summary Table:

| Feedstock Category | Examples | Primary Outputs |

|---|---|---|

| Biomass & Wood Waste | Forest residues, sawmill waste | Bio-oil, Syngas, Biochar |

| Agricultural Residues | Corn stover, wheat straw, rice husks | Bio-oil, Biochar |

| Municipal & Polymeric Waste | MSW, yard waste, plastics | Bio-oil, Syngas |

| Emerging Sources | Algae, invasive species | Varies by composition |

Ready to transform your organic waste streams into valuable products?

KINTEK specializes in lab-scale pyrolysis equipment and consumables, helping you test and optimize the process for your specific feedstock—whether it's biomass, plastics, or agricultural residues. Our experts can help you determine the ideal conditions to maximize yields of bio-oil, syngas, or biochar.

Contact our team today to discuss your project and discover how our solutions can enhance your research and development efforts.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Test Sieves and Sieving Machines

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions