Brazing is an exceptionally versatile joining process capable of bonding a vast array of materials. It is routinely used for common metals like mild steel, stainless steel, copper, and aluminum, as well as more specialized materials including cast iron, nickel alloys, titanium, and even non-metals like ceramics.

The true scope of brazing is not defined by a simple list of materials, but by a single principle: the ability of a filler metal to "wet" and flow across the surfaces being joined. If you can ensure clean, oxide-free surfaces, you can braze an incredibly diverse range of metals, alloys, and ceramics.

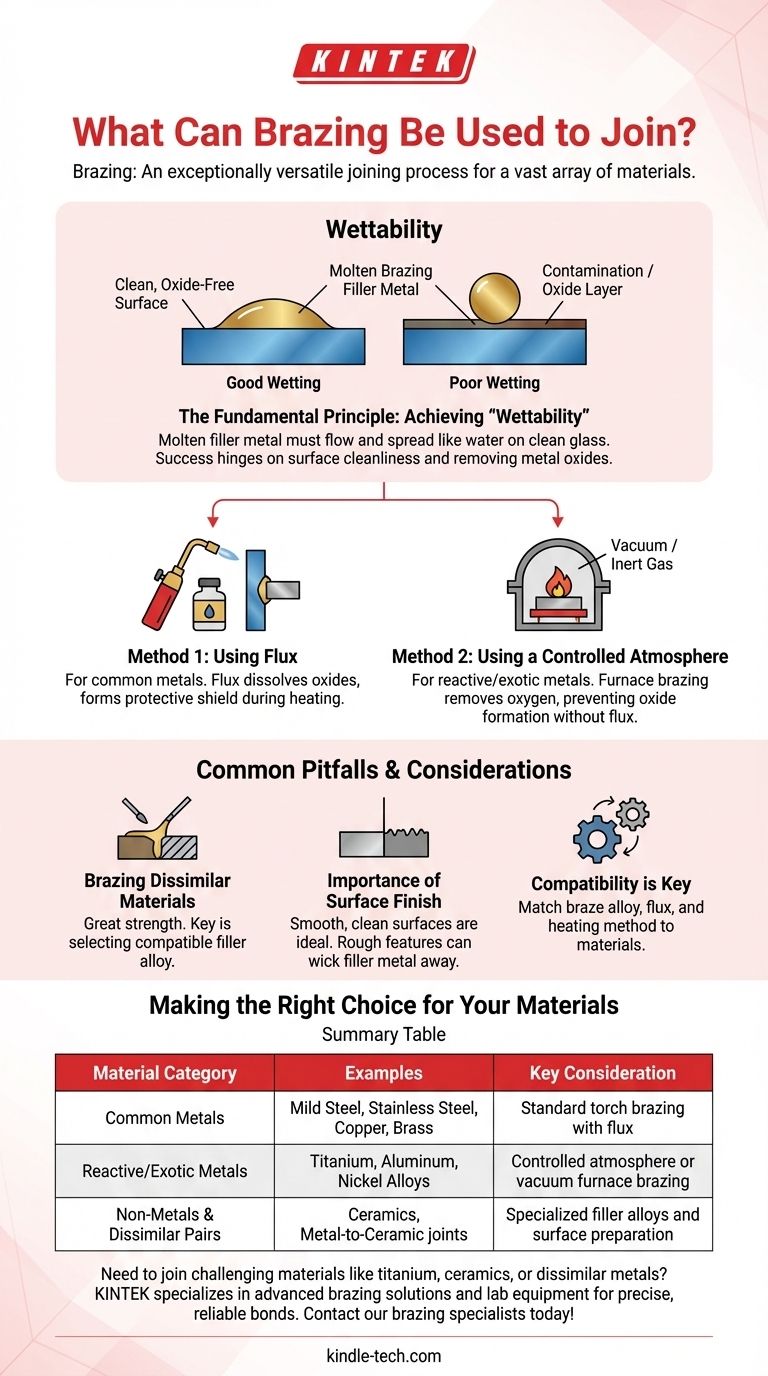

The Fundamental Principle: Achieving "Wettability"

The success of any brazing operation hinges on one critical factor. This factor determines whether a strong, continuous bond can be formed between the parts.

What is "Wetting"?

Wetting is the ability of the molten brazing filler metal to flow and spread evenly over the surfaces of the base materials.

Think of it like water on a pane of glass. On a clean surface, water spreads out into a thin film. On a waxy or greasy surface, it beads up and refuses to spread. The filler metal must act like water on clean glass to create a successful joint.

The Critical Role of Cleanliness

The first step to achieving good wetting is ensuring the components are mechanically clean.

Any contaminants like grease, oil, rust, or metal shavings (swarf) must be completely removed before brazing. These contaminants will prevent the filler metal from making intimate contact with the base material.

The Universal Barrier: Metal Oxides

Virtually all metals react with oxygen in the air to form a thin, invisible layer of oxide on their surface.

This oxide layer is the primary barrier to a successful braze. It acts like the waxy coating on glass, preventing the molten filler metal from wetting the underlying parent material and forming a metallurgical bond.

How Brazing Overcomes the Oxide Barrier

The entire brazing process is designed around removing the existing oxide layer and preventing it from re-forming during the heating cycle. This is accomplished in two primary ways.

Method 1: Using Flux

For many common applications, a flux is used. A flux is a chemical compound applied to the joint area before heating.

As the part is heated, the flux melts and becomes active. It chemically dissolves the metal oxides and forms a protective shield over the joint, preventing new oxides from forming and allowing the filler metal to wet the clean surfaces.

Method 2: Using a Controlled Atmosphere

For materials that are highly reactive (like titanium or aluminum) or for high-volume production, furnace brazing is used.

This process takes place inside a sealed furnace filled with a specific atmosphere—or a vacuum—that contains no oxygen. By removing oxygen from the environment, oxides cannot form during heating, allowing for excellent wetting without the need for chemical fluxes. This is essential for joining exotic and refractory metals.

Common Pitfalls and Considerations

While the range of materials is broad, success requires attention to detail. Certain factors can compromise the integrity of the brazed joint.

Brazing Dissimilar Materials

One of the greatest strengths of brazing is its ability to join dissimilar materials, such as copper to steel or even a metal to a ceramic.

Because the base materials are not melted, issues of metallurgical incompatibility are greatly reduced compared to welding. The key is selecting a filler alloy that is compatible with both materials.

The Importance of Surface Finish

A smooth, clean surface is ideal. Deep score marks, rough shot-blasted areas, or other irregularities near the joint can cause problems.

These rough features can act like a wick, pulling the molten filler metal away from the intended joint area through capillary action, which can starve the joint of the filler it needs.

Compatibility is Key

While almost any material can be brazed, not every filler metal works with every base material. The selection of the braze alloy, the flux, and the heating method must be carefully matched to the materials being joined to ensure a strong, reliable bond.

Making the Right Choice for Your Materials

Your approach to brazing should be dictated entirely by the materials you intend to join.

- If your primary focus is joining common metals (steel, copper, brass): A standard torch brazing process with the correct chemical flux is often the most effective and accessible method.

- If your primary focus is joining reactive or exotic metals (titanium, aluminum, refractory metals): You must use a controlled atmosphere process like vacuum or furnace brazing to prevent catastrophic oxidation.

- If your primary focus is joining dissimilar materials (e.g., ceramic to metal): Success depends on selecting a specialized braze alloy and process designed to ensure proper wetting on both distinct surfaces.

Ultimately, success in brazing comes not from memorizing a list of materials, but from understanding and controlling the conditions at the joint interface.

Summary Table:

| Material Category | Examples | Key Consideration |

|---|---|---|

| Common Metals | Mild steel, stainless steel, copper, brass | Standard torch brazing with flux |

| Reactive/Exotic Metals | Titanium, aluminum, nickel alloys | Controlled atmosphere or vacuum furnace brazing |

| Non-Metals & Dissimilar Pairs | Ceramics, metal-to-ceramic joints | Specialized filler alloys and surface preparation |

Need to join challenging materials like titanium, ceramics, or dissimilar metals? KINTEK specializes in advanced brazing solutions and lab equipment for precise, reliable bonds. Our expertise in controlled atmosphere furnaces and filler metal selection ensures your projects succeed with superior strength and integrity. Contact our brazing specialists today to discuss your specific material joining requirements!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the difference between a 1 stage and 2 stage vacuum? Choose the Right Pump for Your Application

- What are the different design schemes and common mediums used for gas cooling in vacuum furnaces? Optimize Your Heat Treatment Process

- What is var stainless? Discover the Power of Vanadium Stainless Steel for Superior Wear Resistance

- What is the critical application of a vacuum pump system in ion thermochemical treatments? Ensure Superior Bonding

- What is the function of high-temperature chemical reactors for high-purity antimony trioxide? Precision Processing Guide

- What are the two types of quenching? Master Gas vs. Liquid for Superior Heat Treatment

- Why is a high-precision furnace necessary for T91 steel heat treatment? Ensure 1050°C and 770°C Thermal Stability

- What is the vacuum brazing technique? Achieve Superior, Flux-Free Metal Joining