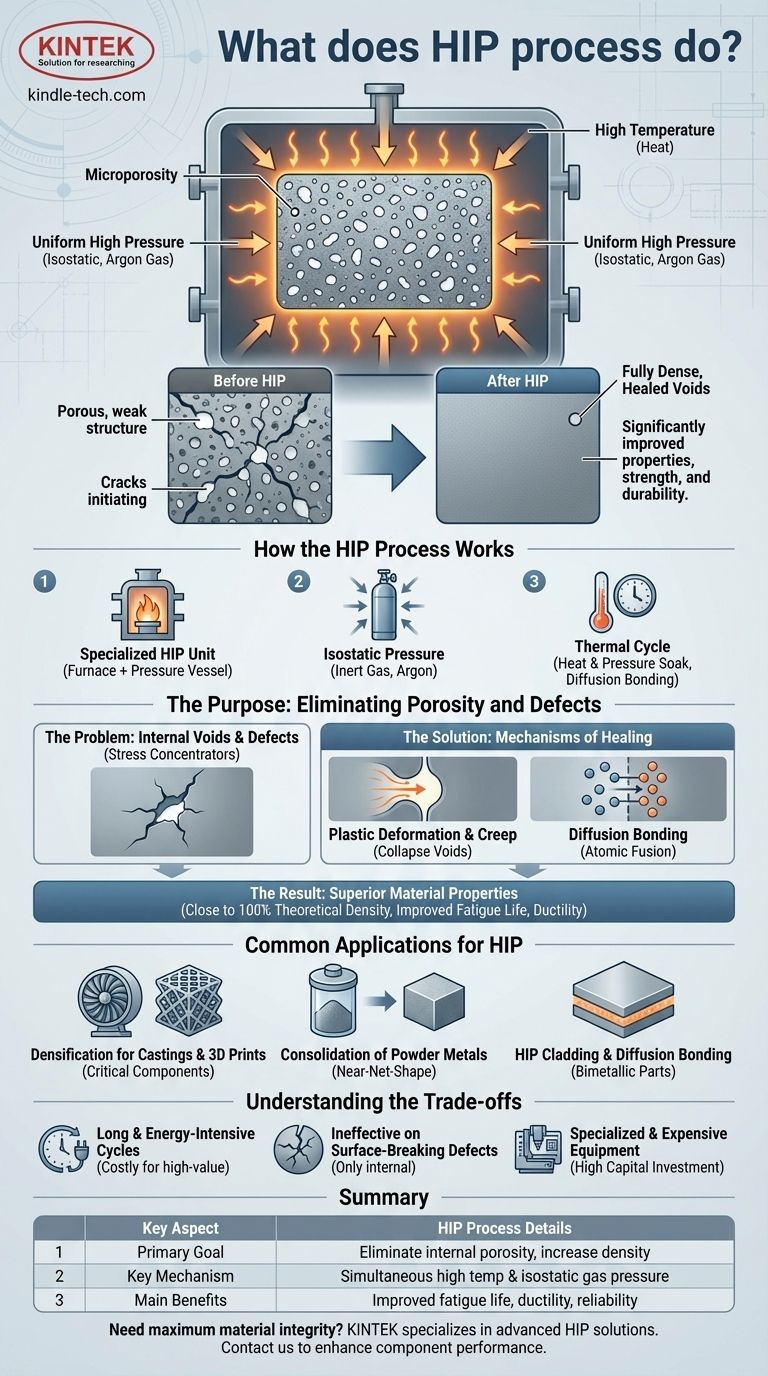

At its core, Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and uniform, high-pressure gas to eliminate internal porosity and increase the density of materials. This simultaneous application of heat and pressure forces internal voids to collapse and diffusionally bond, resulting in a component with significantly improved mechanical properties, strength, and durability.

The central challenge in many advanced manufacturing methods, like casting or 3D printing, is the presence of microscopic internal voids that compromise a part's integrity. Hot Isostatic Pressing directly solves this by acting as a "healing" process, removing that internal porosity to create a fully dense, high-performance final product.

How the HIP Process Works

The effectiveness of HIP lies in its unique combination of three factors: a controlled atmosphere, extreme pressure, and high heat.

The Core Equipment

The entire process takes place inside a specialized HIP unit, which consists of a high-temperature furnace housed within a robust pressure vessel. Components are loaded into this furnace before the cycle begins.

The Role of Isostatic Pressure

Once the vessel is sealed, it is filled with an inert gas, almost always argon. This gas is pressurized to extremely high levels, applying uniform, or isostatic, pressure to the component from all directions simultaneously.

The Thermal Cycle

As pressure increases, the furnace heats the components to a specific, elevated temperature below the material's melting point. The parts are held at this peak temperature and pressure for a set duration, often for several hours. During this "soak time," the material softens enough for the external pressure to collapse any internal voids.

Finally, the vessel is cooled, sometimes rapidly to act as a quenching step, and the pressure is released. The fully densified components are then removed.

The Purpose: Eliminating Porosity and Defects

The primary goal of HIP is to improve the microstructure of a material, which directly enhances its real-world performance.

The Problem of Internal Voids

Processes like metal casting and additive manufacturing (3D printing) can leave behind tiny, trapped pockets of gas or voids known as microporosity. These defects act as stress concentrators and are potential initiation points for cracks and fatigue failure.

The Mechanisms of Healing

HIP eliminates these voids through a combination of physical and metallurgical phenomena.

- Plastic Deformation & Creep: The high pressure physically forces the material to deform and "creep" into the void, collapsing it.

- Diffusion Bonding: At the same time, the high temperature energizes the atoms on the surfaces of the collapsed void, causing them to diffuse across the boundary and form a permanent, solid metallurgical bond.

The Result: Superior Material Properties

By removing these internal defects, HIP produces a part that is close to 100% of its theoretical maximum density. This leads to dramatic improvements in properties like fatigue life, ductility, and fracture toughness.

Common Applications for HIP

HIP is not a primary forming process but a critical enhancement step used across several high-performance industries.

Densification for Castings and 3D Prints

This is the most common use. Critical components for aerospace, energy, and medical implants are often HIPed after casting or printing to guarantee the removal of any internal porosity and ensure maximum reliability.

Consolidation of Powder Metals

HIP can be used to consolidate metal powders into a fully dense, solid shape. The powder is sealed in a canister, and the HIP process fuses the individual particles together into a high-performance, near-net-shape part.

HIP Cladding and Diffusion Bonding

The process can be used to bond different materials together without melting. This is useful for applying a layer of a high-performance or corrosion-resistant alloy onto a less expensive substrate, creating a bimetallic part with tailored properties.

Understanding the Trade-offs

While powerful, the HIP process has specific characteristics and limitations that must be considered.

Long and Energy-Intensive Cycles

A typical HIP cycle can last from eight to twelve hours or more. The high temperatures and pressures required also consume a significant amount of energy, making it a costly process reserved for high-value components.

Ineffective on Surface-Breaking Defects

The HIP process relies on external gas pressure to collapse internal voids. If a defect is open to the surface, the pressurized gas will simply fill the void instead of collapsing it. Parts with surface porosity cannot be fixed with HIP alone.

Specialized and Expensive Equipment

HIP units are complex, high-pressure systems that represent a significant capital investment. For this reason, many companies outsource their HIP requirements to specialized service providers.

Making the Right Choice for Your Goal

Deciding to use HIP depends entirely on the performance requirements and value of your component.

- If your primary focus is reliability in critical applications: Use HIP as a final step for castings and 3D printed parts to eliminate internal defects and maximize fatigue life.

- If your primary focus is producing near-net-shape parts from advanced alloys: Use HIP to consolidate metal powders into a fully dense component, reducing machining waste.

- If your primary focus is creating bimetallic or clad components: Use HIP for diffusion bonding to achieve a strong metallurgical bond without the issues of a welding process.

Ultimately, Hot Isostatic Pressing is the definitive tool for achieving the highest possible material integrity in engineered components.

Summary Table:

| Key Aspect | HIP Process Details |

|---|---|

| Primary Goal | Eliminate internal porosity and increase material density |

| Key Mechanism | Simultaneous high temperature and isostatic gas pressure |

| Common Applications | Castings, 3D printed parts, powder consolidation, diffusion bonding |

| Main Benefits | Improved fatigue life, ductility, fracture toughness, and reliability |

| Limitations | Ineffective on surface defects, long cycle times, high energy consumption |

Need to achieve maximum material integrity for your critical components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing services. Our expertise helps manufacturers in aerospace, medical, and energy sectors eliminate internal defects in castings and 3D printed parts, ensuring superior performance and reliability.

We provide:

- HIP services for porosity elimination and density improvement

- Consultation on material enhancement strategies

- Support for castings, additive manufacturing, and powder metallurgy applications

Contact KINTEK today to discuss how our lab equipment and processing expertise can enhance your component performance and reliability.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Are there different types of annealing? Choose the Right Process for Your Metal

- How does press forging differ from drop forging? Control vs. Speed in Metal Forming

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- What is biomass conversion efficiency? Maximize Your Bioenergy Output and ROI

- What is surface sputtering? A Guide to Precision Thin Film Deposition & Etching

- How does biomass work as a renewable energy? A Carbon-Neutral Power Source Explained

- What types of plastic can be used for pyrolysis? Transform Low-Value Waste into High-Value Resources

- What are the limitations and disadvantages of powder metallurgy? Understanding the Trade-Offs for Your Application