The primary heat treatment processes used to alter the properties of steel are annealing, quenching, tempering, and case hardening. These processes involve precise, controlled cycles of heating and cooling to fundamentally change the steel's internal microstructure. By manipulating this internal structure, we can dial in specific mechanical properties like hardness, toughness, and ductility to meet the demands of a given application.

The core purpose of heat treating steel is not just to heat it up, but to strategically manipulate its internal crystal structure. The specific combination of temperature, time, and cooling rate determines whether the final product is soft and formable, hard and wear-resistant, or tough and durable.

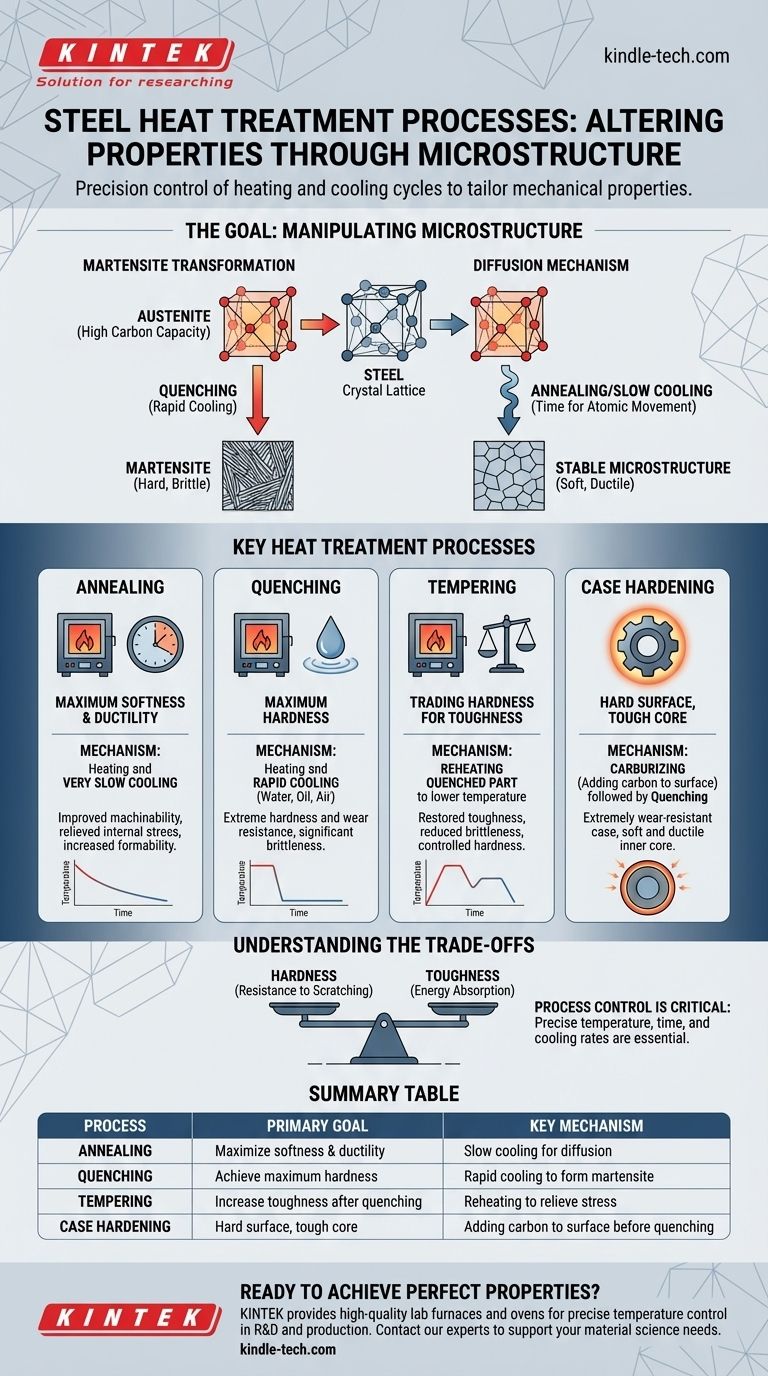

The Goal: Manipulating Steel's Microstructure

Every heat treatment process is designed to alter the microscopic crystal structure, or microstructure, of the steel. The arrangement of iron and carbon atoms at this level dictates the material's large-scale mechanical properties. Two fundamental mechanisms drive these changes.

The Martensite Transformation

When steel is heated to a high temperature, its crystal structure changes into a state called austenite, which can dissolve a large amount of carbon.

If this steel is then cooled very rapidly (a process called quenching), the carbon atoms are trapped. This forces the iron crystals into a highly strained, hard, and brittle structure known as martensite.

The Diffusion Mechanism

When steel is heated and held at temperature or cooled slowly, atoms have time to move around, or diffuse.

This diffusion allows the microstructure to rearrange into more stable, less stressed formations. This mechanism is key to softening steel, relieving internal stresses, and making the material more uniform.

A Breakdown of Key Heat Treatment Processes

While the underlying mechanisms are simple, they are applied through several distinct processes, each with a specific outcome.

Annealing: Maximum Softness and Ductility

Annealing involves heating steel to a specific temperature and then cooling it very slowly.

This slow cooling gives the microstructure ample time to rearrange into its softest, most stable state. The primary goal of annealing is to improve machinability, increase ductility for forming operations, and relieve internal stresses from prior work.

Quenching: Achieving Maximum Hardness

Quenching is the opposite of annealing. It involves heating the steel to its austenitic range and then cooling it as rapidly as possible, typically in water, oil, or air.

This rapid cooling triggers the martensite transformation, producing a material with very high hardness and wear resistance but also significant brittleness.

Tempering: Trading Hardness for Toughness

A quenched part is often too brittle for practical use. Tempering is a secondary heat treatment performed after quenching to restore some toughness.

The part is reheated to a much lower temperature, which relieves the internal stresses within the martensitic structure. The higher the tempering temperature, the more hardness is sacrificed in exchange for increased toughness and ductility.

Case Hardening: A Hard Surface with a Tough Core

Case hardening creates a component with two distinct sets of properties: an extremely hard, wear-resistant outer surface (case) and a softer, tougher inner core.

This is often achieved through processes like carburizing, where carbon is diffused into the surface of a low-carbon steel part at high temperature. The part is then quenched, creating a high-carbon, martensitic case while the low-carbon core remains tough and ductile.

Understanding the Trade-offs

It is impossible to maximize all of steel's properties simultaneously. Heat treatment is always an exercise in managing a critical trade-off.

Hardness vs. Toughness

The most fundamental trade-off in heat-treating steel is between hardness and toughness.

Hardness is the resistance to scratching and indentation. Toughness is the ability to absorb energy and resist fracture. Generally, as you increase a steel's hardness through quenching, you decrease its toughness, making it more brittle. Tempering is the process used to find the ideal balance between these two properties for a specific application.

Process Control is Critical

Heat treatment is a precise science. Minor deviations in temperature, hold times, or cooling rates can lead to a component that does not meet its required specifications. An overheated part can have its grain structure ruined permanently, while an improper quench can lead to cracking or insufficient hardness.

Matching the Process to the Engineering Goal

Selecting the right heat treatment requires a clear understanding of the component's final purpose.

- If your primary focus is machinability or forming: Use annealing to create the softest and most ductile state possible.

- If your primary focus is extreme wear resistance: Use quenching, followed by a low-temperature temper to relieve stress without sacrificing much hardness.

- If your primary focus is a balance of strength and impact resistance: Use quenching followed by a higher-temperature temper to achieve the desired toughness.

- If your primary focus is a wear-resistant surface on a ductile part: Use a case hardening process like carburizing.

Understanding these foundational processes empowers you to specify and create steel components precisely engineered for their intended task.

Summary Table:

| Process | Primary Goal | Key Mechanism |

|---|---|---|

| Annealing | Maximize softness & ductility | Slow cooling for diffusion |

| Quenching | Achieve maximum hardness | Rapid cooling to form martensite |

| Tempering | Increase toughness after quenching | Reheating to relieve stress |

| Case Hardening | Hard surface, tough core | Adding carbon to surface before quenching |

Ready to achieve the perfect material properties for your application? The precise control required for successful heat treatment starts with reliable equipment. At KINTEK, we specialize in high-quality lab furnaces and ovens designed for exact temperature control and uniform heating, essential for processes like annealing, quenching, and tempering. Whether you're in R&D or production, our solutions help you consistently meet your engineering goals. Contact our experts today to discuss how we can support your laboratory's material science needs. Get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How does the isothermal holding function of high-temperature furnaces affect TLP bonding joints? Achieve Seamless Bonds

- What role do high-temperature vacuum or atmosphere furnaces play in the solution treatment of 17-4 PH steel?

- How do high-temperature furnaces facilitate the thermal treatment of halide solid electrolyte materials?

- What is VAR in metallurgy? Achieve Superior Metal Purity and Performance

- Why is a vacuum chamber and heating system maintained at 300°C during deposition? Optimize Coating Adhesion

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- Why is a vacuum environment system necessary for SEP of CuAlMn alloys? Achieve High-Purity Porous Structures

- What are the specific functions of a vacuum oven in VRFB electrode preparation? Enhance Carbon Paper Performance