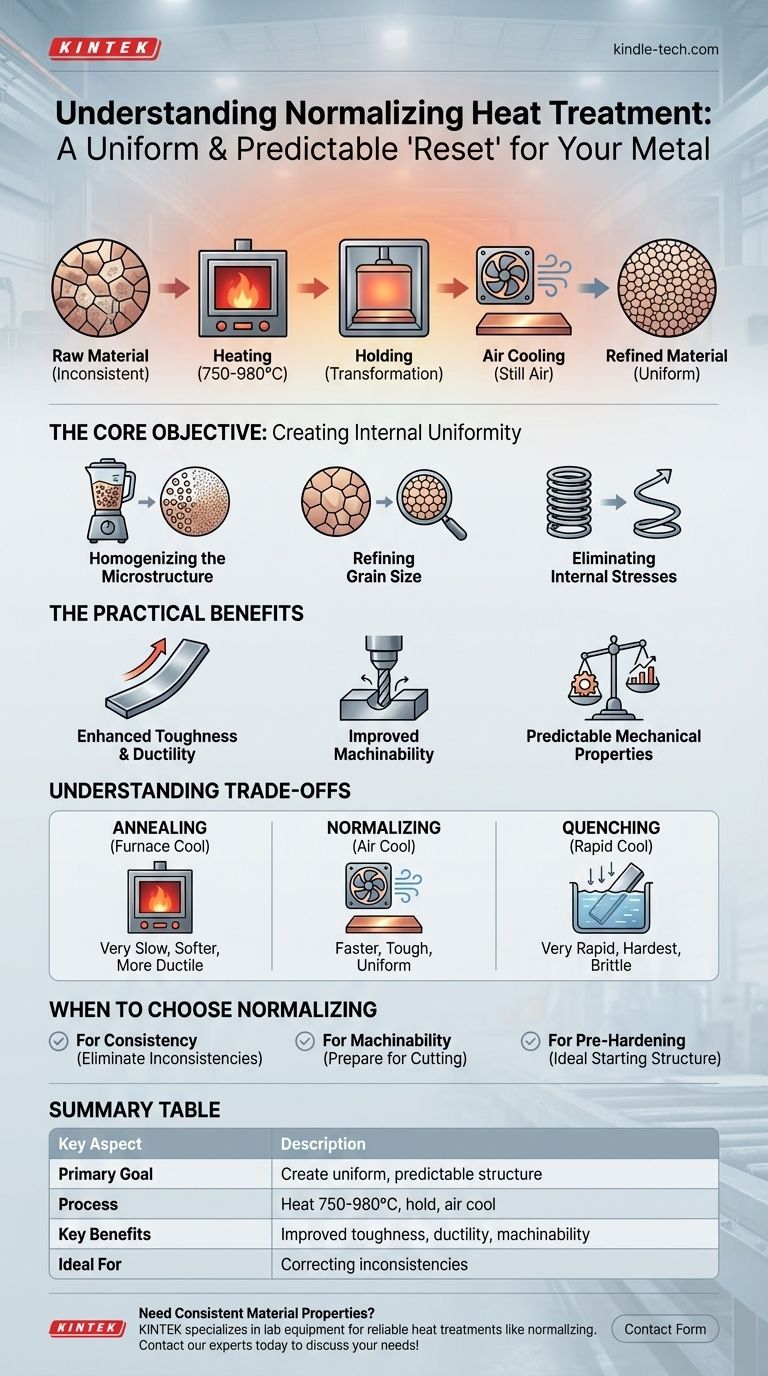

At its core, normalizing is a heat treatment process used to refine a metal's grain structure and create more uniform mechanical properties. The material, typically steel, is heated to a temperature between 750-980 °C (1320-1796 °F), held at that temperature to allow its internal structure to transform, and then cooled in still air. This process improves key characteristics like toughness and machinability.

The fundamental goal of normalizing is not to make a metal exceptionally hard or soft, but to make it uniform and predictable. It acts as a "reset" for the material's microstructure, eliminating inconsistencies introduced during manufacturing processes like casting or forging.

The Core Objective: Creating Internal Uniformity

Manufacturing processes like forging, rolling, or casting often leave a metal with an inconsistent and stressed internal structure. This leads to unpredictable performance. Normalizing is specifically designed to correct these issues.

Homogenizing the Microstructure

The primary goal is to create a homogenous, or uniform, internal structure. Processes like casting can create large, non-uniform crystals (grains) as the metal cools. Normalizing breaks down this coarse structure into a more consistent state.

Refining Grain Size

By heating the metal above its critical transformation temperature and then air-cooling it, normalizing forces the formation of new, smaller, and more evenly distributed grains. A fine-grained structure is generally stronger and tougher than a coarse-grained one.

Eliminating Internal Stresses

The heating and subsequent transformation during normalizing relieve the internal stresses that can be locked into the material during manufacturing. This reduces the risk of distortion or cracking during subsequent machining or use.

The Practical Benefits of Normalizing

Correcting the microstructure translates directly into measurable improvements in the material's performance and usability.

Enhanced Toughness and Ductility

Normalizing generally increases a material's toughness (its ability to absorb energy and resist fracturing) and ductility (its ability to deform without breaking). This makes the final component more durable and reliable.

Improved Machinability

A uniform microstructure is far easier to machine consistently. It eliminates hard and soft spots, leading to better tool life, a superior surface finish, and more predictable cutting operations.

Predictable Mechanical Properties

After normalizing, the mechanical properties across the entire piece of metal are far more consistent. This ensures that the component will behave as expected when put under load, which is a critical factor for engineering applications.

Understanding the Trade-offs and Distinctions

Normalizing is often confused with other common heat treatments like annealing and quenching. The key difference lies in the cooling rate and the resulting properties.

Normalizing vs. Annealing

Annealing involves a much slower cooling process, typically allowing the material to cool down inside the furnace. This results in a softer, more ductile material with lower strength. Normalizing's air cooling is faster, producing a slightly harder and stronger material.

Normalizing vs. Quenching

Quenching is a very rapid cooling process (using water, oil, or polymer) designed to achieve maximum hardness. Normalizing is a far less severe treatment and does not create the high hardness—or the associated brittleness—that quenching does. It is often used as a preliminary step to refine the grain structure before a final quenching and tempering process.

When to Choose Normalizing

Selecting the right heat treatment depends entirely on your end goal for the material.

- If your primary focus is consistency: Use normalizing to eliminate the non-uniform microstructures created by forging, casting, or welding.

- If your primary focus is improving machinability: Normalizing is an excellent choice to prepare a raw material for extensive cutting operations by ensuring a uniform response to the tool.

- If your primary focus is preparing for further hardening: Use normalizing to create an ideal, fine-grained starting structure before a final quench and temper operation.

Ultimately, normalizing serves as the crucial step to ensure a metal's internal structure is uniform, predictable, and ready for its final application.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Create a uniform, predictable internal grain structure. |

| Process | Heat to 750-980°C, hold, then cool in still air. |

| Key Benefits | Improved toughness, ductility, and machinability. |

| Ideal For | Correcting inconsistencies from forging, casting, or welding. |

Need to ensure your materials have consistent, predictable properties? KINTEK specializes in the precise lab equipment and consumables required for reliable heat treatment processes like normalizing. Our solutions help you achieve superior material performance and repeatable results. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan