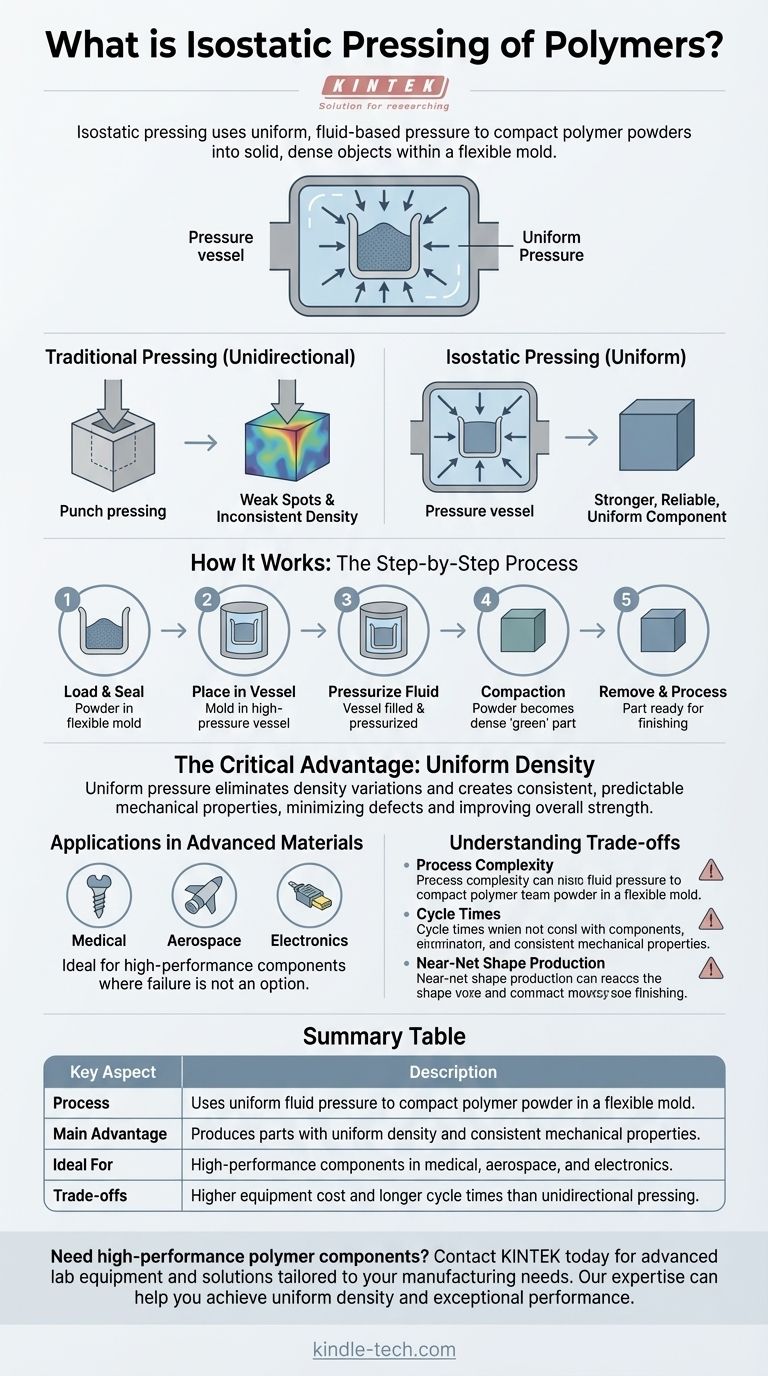

In essence, isostatic pressing of polymers is a manufacturing process that uses uniform, fluid-based pressure to compact polymer powders into a solid, dense object. The polymer powder is sealed in a flexible mold, which is then submerged in a liquid inside a pressure vessel. As the liquid is pressurized, it applies equal force from all directions, compacting the powder into a highly uniform component.

Traditional pressing compacts powder from one direction, creating weak spots and inconsistent density. Isostatic pressing solves this by using a fluid to apply equal pressure from all sides, resulting in a stronger, more reliable final polymer component.

How Isostatic Pressing Works

The Core Principle: Uniform Pressure

The process works based on the fundamental principle of fluid dynamics that pressure exerted on a confined fluid is transmitted equally in all directions.

This hydrostatic pressure ensures that every surface of the powder mass inside the flexible mold receives the exact same amount of compressive force simultaneously.

The Key Components

The system consists of three main parts: a pressure vessel to contain the process, a fluid medium (like water or oil) to transmit the pressure, and a flexible mold (typically made of rubber or plastic) to hold the polymer powder.

The mold is the key to creating the part's shape, while the fluid is the key to achieving uniform compaction.

The Step-by-Step Process

- Polymer powder (often a high-performance resin) is loaded and sealed inside the flexible mold.

- The sealed mold is placed into the high-pressure vessel.

- The vessel is filled with the fluid medium and then pressurized to a specific level.

- This pressure compacts the powder into a dense, solid "green" part that holds its shape.

- After depressurization, this part can be removed for any final processing, like sintering or machining.

The Critical Advantage: Uniform Density

Overcoming Unidirectional Flaws

Conventional die pressing compacts powder by pushing down from the top. This creates significant friction against the die walls, resulting in density variations throughout the part. The areas furthest from the punch are often less dense.

Isostatic pressing eliminates this issue entirely, as there is no single direction of force.

The Impact of Uniformity

A uniformly dense component has more consistent and predictable mechanical properties. This minimizes internal stresses, reduces the potential for warping or cracking during subsequent heating, and dramatically improves overall strength and reliability.

This makes the method ideal for manufacturing high-performance components where failure is not an option.

Applications in Advanced Materials

This process is used across numerous industries for materials like ceramics, metals, and composites. For polymers, it is particularly valuable for processing advanced resin powders into components for the medical, aerospace, and electronics industries.

Think of insulators, connectors, or artificial bone materials where material integrity is paramount.

Understanding the Trade-offs

Process Complexity

Isostatic pressing systems are more complex than simple mechanical presses. They involve high-pressure hydraulics and careful sealing, which can lead to higher initial equipment costs and maintenance requirements.

Cycle Times

The process of filling a vessel with fluid, building pressure, holding it, and then safely depressurizing can take longer than the rapid cycle of a mechanical press. This can make it less suitable for high-volume, low-cost production.

Near-Net Shape Production

While the flexible molds allow for complex geometries, the resulting parts are typically "near-net shape." This means they are very close to their final dimensions but may require some final machining to meet tight tolerances.

When to Choose Isostatic Pressing for Polymers

To determine if this process is right for your application, consider your primary goal.

- If your primary focus is maximum material performance and reliability: Isostatic pressing is the superior choice for creating components with uniform density and predictable mechanical properties.

- If your primary focus is creating complex shapes that are difficult to mold: The use of a flexible mold allows for more intricate geometries than are possible with rigid, unidirectional dies.

- If your primary focus is reducing internal defects in a final part: The uniform pressure minimizes the voids and density gradients that often lead to part failure under stress.

By leveraging uniform fluid pressure, isostatic pressing transforms polymer powders into highly consistent components engineered for the most demanding applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Uses uniform fluid pressure to compact polymer powder in a flexible mold. |

| Main Advantage | Produces parts with uniform density and consistent mechanical properties. |

| Ideal For | High-performance components in medical, aerospace, and electronics. |

| Trade-offs | Higher equipment cost and longer cycle times than unidirectional pressing. |

Need to manufacture high-performance polymer components with superior strength and reliability?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your precise manufacturing needs. Our expertise in isostatic pressing technology can help you achieve uniform density and exceptional material performance for your most demanding applications in the medical, aerospace, and electronics industries.

Contact us today to discuss how our solutions can enhance your polymer component production and deliver the consistent quality your projects require.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press for Solid State Battery Research

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- What is the benefit of using a cold isostatic press for the secondary treatment of TiC10/Cu-Al2O3? Boost Density Now!

- Why is a Cold Isostatic Press (CIP) used for copper composite powders? Enhance Sintering Efficiency and Density

- Is isostatic pressing expensive? Achieve Superior Material Uniformity & Complex Shapes

- How does a Cold Isostatic Press (CIP) contribute to the fabrication of HE-O-MIEC and LLZTO? Expert Densification Guide

- What is the cold CIP process? Achieve Uniform Density in Complex Powdered Parts

- How is isostatic pressing distinguished from conventional pressing? Unlock Superior Uniformity and Density

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- What is the role of a Cold Isostatic Press (CIP) in C-PSC lamination? Enhance Solar Efficiency Without Heat