In essence, PVD coating is a high-performance surface treatment used to apply a thin, incredibly durable layer of metal-ceramic material onto cutlery. Through a process called Physical Vapor Deposition (PVD), a solid material like titanium is vaporized in a vacuum and then deposited, atom by atom, onto the stainless steel. This creates a finish that is atomically bonded to the surface, making it exceptionally resistant to wear, corrosion, and fading.

The crucial takeaway is that PVD is not a paint or a simple plating. It is a sophisticated vacuum process that fundamentally enhances the surface properties of the cutlery, creating a finish that is often harder and more resilient than the underlying steel itself.

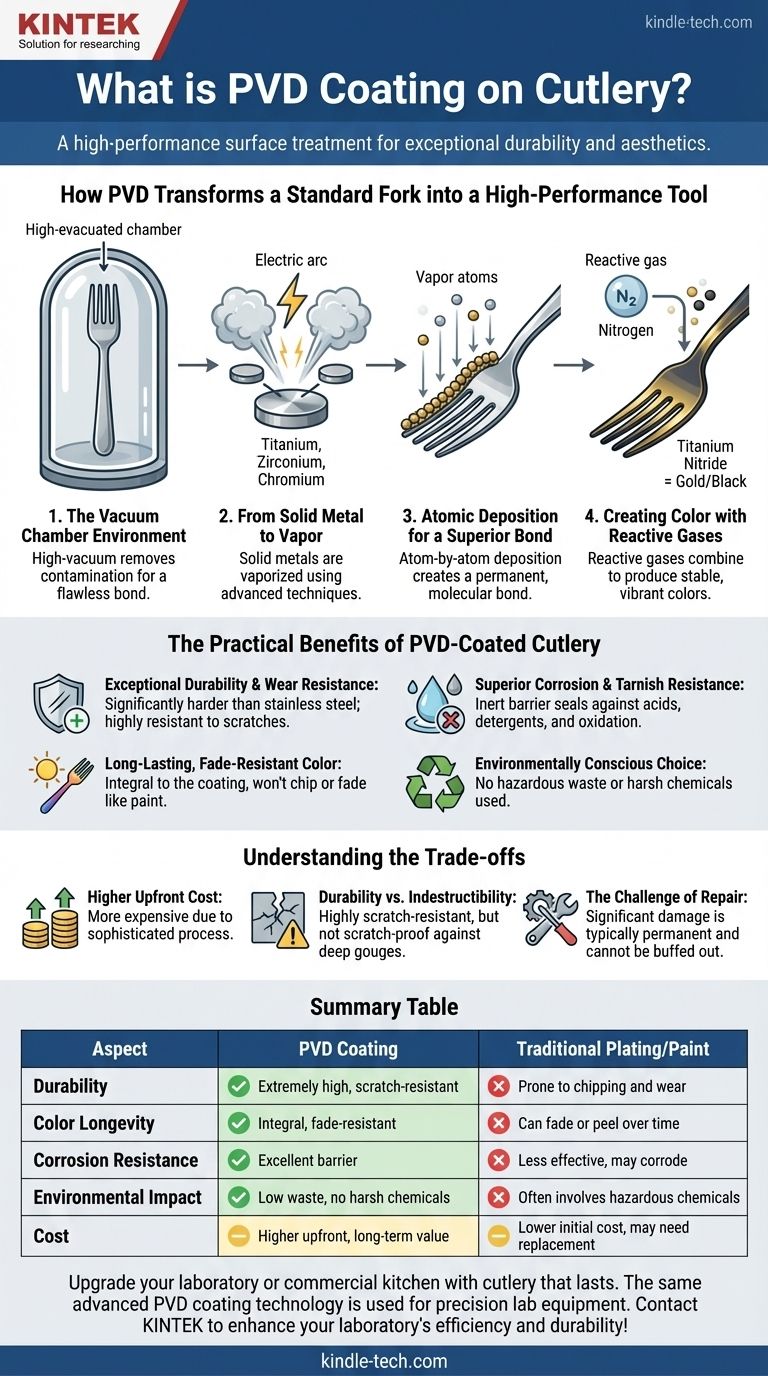

How PVD Transforms a Standard Fork into a High-Performance Tool

To understand the value of PVD, it’s important to understand the process. It's a precise, multi-stage operation conducted in a controlled environment to ensure a flawless and permanent bond.

The Vacuum Chamber Environment

The entire process takes place inside a high-vacuum chamber. This vacuum is critical because it removes virtually all other atoms, preventing contamination and ensuring the vaporized coating material travels in a straight line to the cutlery.

From Solid Metal to Vapor

Small pieces of solid, high-purity metals like titanium, zirconium, or chromium are placed inside the chamber. These "targets" are then vaporized using advanced techniques like an electric arc or ion bombardment.

Atomic Deposition for a Superior Bond

This metal vapor travels through the chamber and deposits onto the cutlery with high energy. This atom-by-atom deposition creates an extremely dense, thin, and uniform layer that is bonded to the steel at a molecular level, making it nearly impossible to remove.

Creating Color with Reactive Gases

To achieve different colors (like gold, black, or rose gold), a reactive gas such as nitrogen is precisely introduced into the chamber. This gas combines with the metal vapor to form a metal-ceramic compound (e.g., titanium nitride), which possesses both exceptional hardness and a specific, stable color.

The Practical Benefits of PVD-Coated Cutlery

The advanced nature of the PVD process translates directly into tangible benefits for the end user, impacting both longevity and aesthetics.

Exceptional Durability and Wear Resistance

The metal-ceramic layer created by PVD is significantly harder than stainless steel. This makes the cutlery highly resistant to daily wear and tear, including minor scratches from use and cleaning.

Superior Corrosion and Tarnish Resistance

The PVD coating acts as an inert barrier, effectively sealing the stainless steel from exposure to acids, alkaline detergents, and oxidation. This means the finish will not tarnish or corrode over time.

Long-Lasting, Fade-Resistant Color

Because the color is an integral part of the coating's structure, it does not fade or chip away like traditional paints or platings. The finish remains consistent and vibrant even after years of use and washing.

An Environmentally Conscious Choice

PVD is recognized as an environmentally friendly process. It produces no hazardous waste and avoids the use of the harsh chemicals often associated with traditional electroplating.

Understanding the Trade-offs

While PVD offers superior performance, an objective assessment requires acknowledging its practical limitations. True expertise means understanding both the strengths and the weaknesses of a technology.

Higher Upfront Cost

The sophisticated equipment and multi-step process—from intensive cleaning and preparation to the vacuum deposition itself—make PVD-coated cutlery more expensive than standard stainless steel flatware.

Durability vs. Indestructibility

PVD coating is highly scratch-resistant, but it is not completely scratch-proof. A deep gouge from a sharp knife or significant abrasive force can still penetrate the coating and damage the surface.

The Challenge of Repair

Due to the nature of the atomic bond, a scratch or chip in a PVD coating cannot be simply "buffed out" or repaired. Any significant damage to the coating is typically permanent.

Making the Right Choice for Your Needs

Selecting the right cutlery depends on balancing your priorities for performance, aesthetics, and budget.

- If your primary focus is everyday durability and low maintenance: PVD is an excellent investment that will withstand daily use and dishwashing far better than any other colored finish.

- If your primary focus is aesthetic appeal for special occasions: The consistent, fade-proof colors of PVD offer a striking visual that won't tarnish or require polishing like traditional silver-plated items.

- If your primary focus is a high-impact commercial environment (e.g., a restaurant): The superior wear and corrosion resistance makes PVD a strong candidate for maintaining a high-end look despite heavy use and industrial dishwashing.

Ultimately, choosing PVD-coated cutlery is an investment in long-term performance and enduring style.

Summary Table:

| Aspect | PVD Coating | Traditional Plating/Paint |

|---|---|---|

| Durability | Extremely high, scratch-resistant | Prone to chipping and wear |

| Color Longevity | Integral to coating, fade-resistant | Can fade or peel over time |

| Corrosion Resistance | Excellent barrier against tarnish | Less effective, may corrode |

| Environmental Impact | Low waste, no harsh chemicals | Often involves hazardous chemicals |

| Cost | Higher upfront, long-term value | Lower initial cost, may need replacement |

Upgrade your laboratory or commercial kitchen with cutlery that lasts. The same advanced PVD coating technology that creates durable, high-performance cutlery is also used to protect and enhance precision lab equipment. At KINTEK, we specialize in supplying robust laboratory equipment and consumables designed to withstand rigorous use and harsh environments. Whether you need corrosion-resistant components or durable tools for your lab, our expertise ensures you get reliable, long-lasting solutions.

Contact us today to learn how KINTEK can enhance your laboratory's efficiency and durability with our specialized equipment!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology