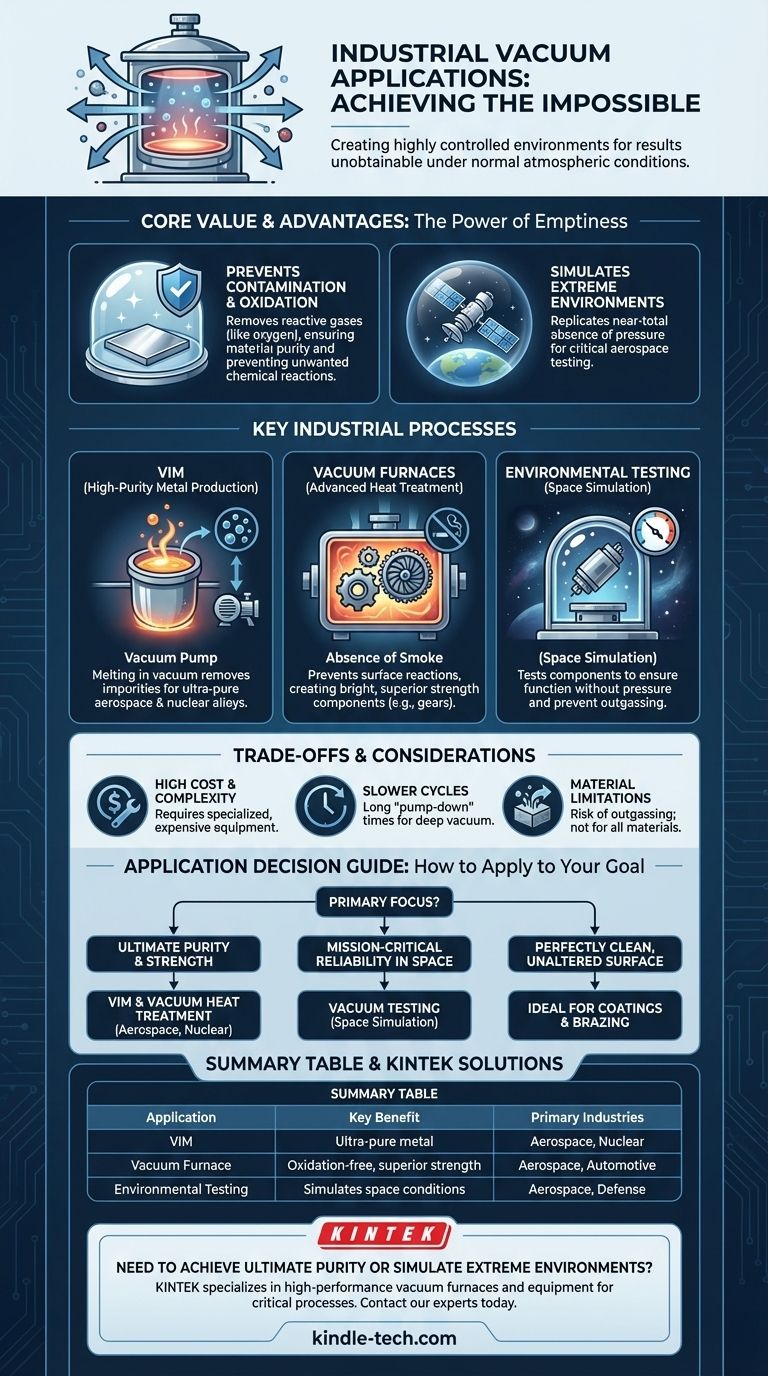

At its core, industrial vacuum application is about creating a highly controlled environment to achieve results that are impossible under normal atmospheric conditions. Key industries like aerospace, automotive, and nuclear engineering rely on vacuum technology for processes such as high-purity metal melting, advanced heat treatment in furnaces, and the critical environmental testing of components.

The primary value of a vacuum in industry is not that it's empty, but rather what its emptiness removes: reactive gases like oxygen. This prevents unwanted chemical reactions and creates an ultra-clean environment essential for producing high-performance materials and testing sensitive equipment.

Why a Vacuum is a Powerful Industrial Tool

To understand the applications, we must first understand the fundamental advantages of removing air and other gases from a sealed chamber. This process fundamentally changes the rules of chemistry and physics for the materials inside.

Preventing Contamination and Oxidation

Most industrial processes involving heat, especially with metals, are vulnerable to oxidation and contamination from gases in the air. A vacuum removes these reactive elements.

This ensures that the material's surface and internal structure remain pure and unaltered during treatment, leading to superior strength and performance.

Simulating Extreme Environments

For certain industries, particularly aerospace, replicating the conditions of outer space is not a luxury—it's a necessity.

A vacuum chamber is the only way to accurately simulate the near-total absence of pressure and atmosphere that spacecraft and their components will experience.

Key Industrial Applications

The principles of contamination control and environmental simulation give rise to several critical industrial processes.

High-Purity Metal Production (VIM)

Vacuum Induction Melting (VIM) is a process used to produce extremely pure metals and superalloys, which are vital for the aerospace and nuclear industries.

By melting the metal in a vacuum, volatile impurities are boiled off and removed, resulting in a cleaner, stronger, and more reliable final product.

Advanced Heat Treatment (Vacuum Furnaces)

Vacuum furnaces are essential in the aerospace and automotive sectors for heat-treating critical metal parts like gears and turbine blades.

The process, conducted in a vacuum, prevents surface reactions like oxidation, resulting in a bright, clean finish and superior mechanical properties without the need for subsequent cleaning.

Environmental Testing for Space

Before a satellite or any component is launched into orbit, it must be proven to withstand the harsh environment of space.

Vacuum chambers are used to test these components, ensuring that they can function reliably without pressure and that materials will not degrade or release gases ("outgas") in a way that could damage sensitive electronics or optics.

Understanding the Trade-offs

While powerful, vacuum technology is not a universal solution. It involves specific challenges that make it suitable only for high-value applications where the benefits justify the costs.

High Cost and Complexity

Creating and maintaining an industrial-grade vacuum requires expensive, specialized equipment, including robust chambers, powerful pumps, and precise monitoring gauges.

Slower Process Cycles

Achieving a deep vacuum is not instantaneous. The "pump-down" time required to evacuate a chamber can add significant time to production cycles compared to processes run at atmospheric pressure.

Material Limitations

Not all materials are suitable for use in a vacuum. Some can release trapped gases or vaporize at low pressures, a phenomenon known as outgassing, which can contaminate the vacuum environment or damage the material itself.

How to Apply This to Your Goal

The decision to use a vacuum process depends entirely on the required outcome for your material or component.

- If your primary focus is ultimate material purity and strength: Vacuum induction melting and furnace heat treatment are the correct paths for creating components that cannot fail, such as in aerospace or nuclear applications.

- If your primary focus is mission-critical reliability in space: Vacuum testing is non-negotiable to simulate the operational environment and guarantee that a component will survive and function as designed.

- If your primary focus is achieving a perfectly clean, unaltered surface: A vacuum provides the ideal environment for high-stakes processes like brazing or applying specialty coatings, where any contamination would lead to failure.

Ultimately, vacuum technology is the definitive tool for achieving a level of material control and environmental simulation that is simply out of reach otherwise.

Summary Table:

| Application | Key Benefit | Primary Industries |

|---|---|---|

| Vacuum Induction Melting (VIM) | Ultra-pure metal production | Aerospace, Nuclear |

| Vacuum Furnace Heat Treatment | Oxidation-free, superior strength parts | Aerospace, Automotive |

| Environmental Testing | Simulates space conditions for reliability | Aerospace, Defense |

Need to achieve ultimate purity or simulate extreme environments in your lab? KINTEK specializes in high-performance vacuum furnaces and equipment for critical laboratory processes. Whether you're developing advanced alloys or testing components for space, our solutions deliver the contamination-free environment you need for success. Contact our experts today to discuss how we can support your specific application.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why Are Multi-Zone Melting Systems Necessary for TlBr Crystals? Achieve Semiconductor-Grade Purity

- What precautions should be taken during heat treatment? Essential Safety and Quality Control Measures

- What gas can be used for brazing? Select the Right Atmosphere for Metallurgical Success

- What are powder sintering methods? A Guide to Metal & Ceramic Part Manufacturing

- What temperature is brazing copper? Master the Heat for Perfect Joints

- What impact do high-temperature drying and calcination equipment have on apatite-nepheline waste properties?

- What is the temperature of a calcination furnace? Precise Control from 800°C to 1300°C

- What role does a high-temperature vacuum furnace play in the tungsten coating workflow? Optimize Stress Relief Today