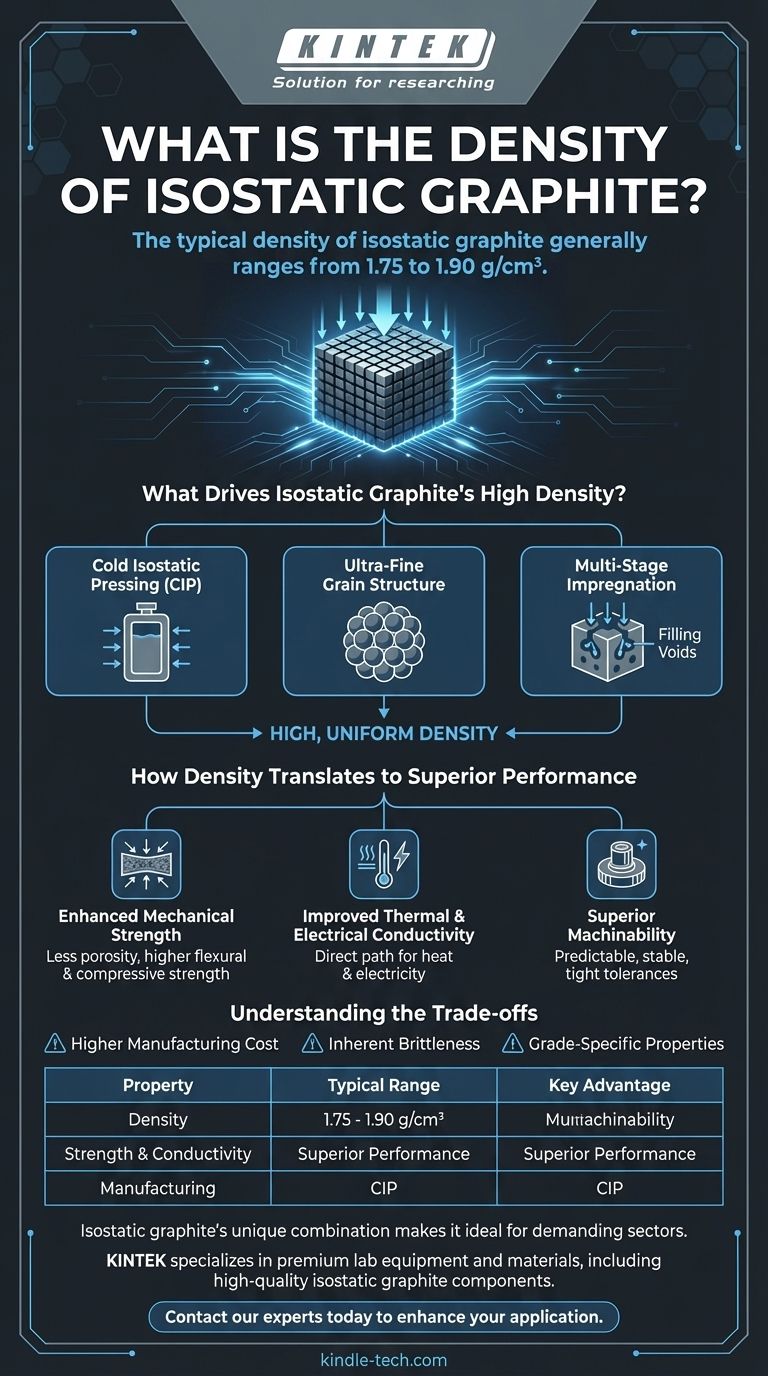

The typical density of isostatic graphite generally ranges from 1.75 to 1.90 g/cm³. This high density is a direct result of its unique manufacturing process and is the primary reason for its superior mechanical and thermal properties compared to other graphite grades.

The key takeaway is not just the specific density value, but understanding that this high, uniform density—achieved through isostatic pressing—is what gives the material its exceptional strength, conductivity, and machinability for demanding applications.

What Drives Isostatic Graphite's High Density?

The defining characteristics of isostatic graphite are born from its specialized manufacturing method. Unlike simpler processes like extrusion, this method is designed to create a near-perfectly uniform and dense material.

The Isostatic Pressing Process

The core of the process involves Cold Isostatic Pressing (CIP). A fine-grain graphite powder mixture is subjected to extremely high, uniform pressure from all directions using a liquid medium.

This uniform pressure compacts the particles far more effectively than unidirectional pressing, minimizing internal voids and ensuring consistent density throughout the entire block.

Ultra-Fine Grain Structure

Isostatic graphite is produced using ultra-fine grain graphite particles. Smaller particles can pack together more tightly, leaving less empty space (porosity) between them.

This tight packing is fundamental to achieving both high density and a smooth, flawless surface finish after machining.

Multi-Stage Impregnation

After the initial pressing and baking (carbonizing), the material still contains some microscopic pores.

The block is then impregnated with pitch under vacuum and pressure, filling these remaining voids. This step is often repeated to further increase density and strength before the final high-temperature graphitization phase.

How Density Translates to Superior Performance

A material's density is directly linked to its physical properties. For isostatic graphite, its high and uniform density is the source of its advantages in advanced engineering.

Enhanced Mechanical Strength

Higher density means less porosity. Pores are microscopic defects that act as stress concentration points where cracks can initiate.

By minimizing these voids, isostatic graphite exhibits significantly higher flexural and compressive strength than less dense graphite grades, and its strength even increases with temperature.

Improved Thermal and Electrical Conductivity

Fewer pores and better contact between graphite particles create a more direct path for heat and electricity to flow.

This results in the excellent thermal and electrical conductivity noted for the material, making it ideal for applications like heat sinks, electrodes, and furnace components.

Superior Machinability

The combination of an ultra-fine grain structure and high density makes the material highly predictable and stable during machining.

It can be machined to extremely tight tolerances with a glass-smooth surface finish, free from the chipping or pitting that can occur in more porous graphite.

Understanding the Trade-offs

While isostatic graphite offers premium performance, it's essential to recognize its limitations to make an informed decision.

Higher Manufacturing Cost

The multi-stage process—including fine powder preparation, high-pressure isostatic pressing, and multiple impregnation cycles—is significantly more complex and expensive than that of conventional graphite.

This results in a higher material cost, which may not be justifiable for less demanding applications.

Inherent Brittleness

Like all graphites and ceramics, isostatic graphite is a brittle material. Despite its high compressive strength, it has low tensile strength and can fracture without warning under sharp impact or excessive flexing.

Design considerations must account for this behavior to avoid component failure.

Grade-Specific Properties

"Isostatic graphite" is a category, not a single material. The exact density, grain size, and resulting properties can vary significantly between different grades and manufacturers.

Engineers must always consult the specific data sheet for the exact grade being considered to ensure it meets the requirements of their application.

Making the Right Choice for Your Application

Selecting the correct material grade requires matching its properties to your primary goal.

- If your primary focus is maximum performance and reliability: Isostatic graphite is the clear choice for critical components in semiconductor, nuclear, or EDM applications where failure is not an option.

- If your primary focus is cost-efficiency for general use: A conventional extruded or molded graphite will likely provide adequate performance for applications like bearings or crucibles at a lower cost.

- If your primary focus is intricate geometry and thermal management: The superior machinability and high thermal conductivity of isostatic graphite make it ideal for complex parts like heat exchangers or rocket nozzles.

Ultimately, choosing the right material depends on a clear understanding of how its fundamental properties, starting with density, drive its performance in your specific environment.

Summary Table:

| Property | Typical Range for Isostatic Graphite |

|---|---|

| Density | 1.75 - 1.90 g/cm³ |

| Key Advantage | Superior Mechanical Strength & Thermal Conductivity |

| Primary Manufacturing Process | Cold Isostatic Pressing (CIP) |

Need a high-performance material for a critical application?

Isostatic graphite's unique combination of high density, strength, and thermal conductivity makes it the ideal choice for demanding sectors like semiconductor manufacturing, EDM, and aerospace.

KINTEK specializes in premium lab equipment and materials, including high-quality isostatic graphite components. We provide the reliable materials and expert support you need to ensure your project's success.

Contact our experts today to discuss how isostatic graphite can enhance your application's performance and reliability.

Visual Guide

Related Products

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- Does graphite lead electricity? Unlocking the Secrets of Its Atomic Structure

- What are the advantages of biomass? Unlock Renewable Power from Waste and Crops

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- What role does convection play in heat transfer? Understanding Heat Movement in Fluids

- What is the function of graphite material when preparing Ga-LLZO sintered bodies? Ensure Sample Integrity in HIP