At its core, the difference between the KBr pellet technique and Attenuated Total Reflectance (ATR) in FTIR spectroscopy is a fundamental distinction between how the infrared light interacts with the sample. The KBr method is a transmission technique, where light passes through a diluted sample. In contrast, ATR is a surface reflectance technique, where light skims the surface of a neat sample, requiring little to no preparation.

The choice between KBr and ATR is not about which is "better," but which is the appropriate tool for your specific sample and analytical goal. KBr provides a classic bulk analysis that is labor-intensive, while ATR offers speed and simplicity for surface-sensitive analysis.

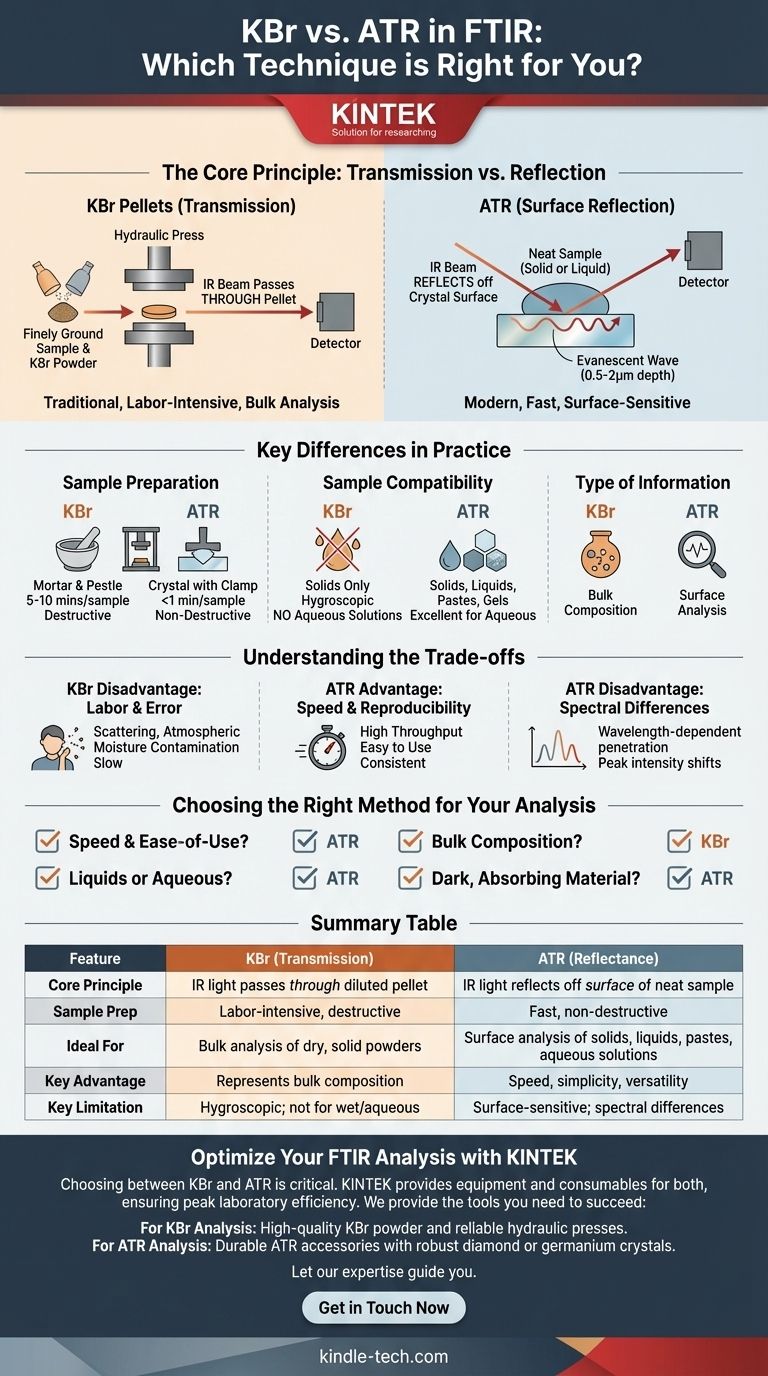

The Core Principle: Transmission vs. Reflection

The method you choose dictates every aspect of your experiment, from sample preparation to the type of information you can obtain.

KBr Pellets: Analyzing by Transmission

The KBr pellet method is a traditional technique for analyzing solid samples. The sample is finely ground and intimately mixed with dry potassium bromide (KBr) powder.

This mixture, typically containing only about 1% sample by weight, is then compressed under high pressure to form a small, semi-transparent disc or "pellet."

KBr is used because it is transparent to infrared light in the analytical region. The IR beam passes directly through the pellet, and the detector measures the light that was not absorbed by the sample dispersed within it.

ATR: Analyzing by Surface Reflection

ATR is a modern technique that has become a workhorse in most labs due to its simplicity. It does not require sample dilution or pellet pressing.

Instead, the sample (either a solid or a liquid) is pressed directly against a small, highly durable crystal with a high refractive index, such as diamond or germanium.

The IR beam is directed into the ATR crystal. It reflects internally, creating a subtle energy field—an evanescent wave—that extends a very short distance (typically 0.5-2 micrometers) beyond the crystal surface and into your sample.

The sample absorbs energy from this wave at its characteristic frequencies. The "attenuated" or weakened light beam is then reflected back into the instrument for detection. This is fundamentally a surface measurement.

Key Differences in Practice

The choice of technique has significant practical consequences for your workflow and results.

Sample Preparation

KBr: This method is destructive and labor-intensive. It requires careful weighing, extensive grinding with a mortar and pestle to reduce particle size, mixing, and pressing in a hydraulic press. The entire process can take 5-10 minutes per sample.

ATR: This method is non-destructive and exceptionally fast. You simply place a small amount of the sample on the crystal, apply pressure with a built-in clamp to ensure good contact, and begin your measurement. Cleanup involves wiping the crystal clean. A sample can be run in under a minute.

Sample Compatibility

KBr: This method is only suitable for solids that can be ground into a fine powder. Crucially, because KBr is a salt, it is hygroscopic (absorbs water from the air) and will dissolve in water. Therefore, it cannot be used for aqueous solutions or very wet samples.

ATR: This is an incredibly versatile technique. It works excellently with solids, powders, films, pastes, gels, and liquids. Because the crystal (like diamond) is inert and non-porous, ATR is the go-to method for analyzing aqueous solutions.

Type of Information Gathered

KBr: By grinding the sample, you create a homogenous mixture. The resulting spectrum is therefore representative of the bulk composition of the material.

ATR: Since the evanescent wave only penetrates a few micrometers deep, ATR is inherently a surface analysis technique. If your sample's surface is chemically different from its bulk (e.g., due to oxidation, coating, or contamination), ATR will primarily detect the surface layer.

Understanding the Trade-offs

Neither method is perfect; each has advantages and disadvantages you must consider.

The KBr Disadvantage: Labor and Error

The main drawback of the KBr method is the potential for error. Uneven grinding can cause scattering effects and distorted peaks. Contamination from atmospheric moisture is common, leading to large, unwanted water peaks in the spectrum. The process is slow and requires significant operator skill to achieve reproducibility.

The ATR Advantage: Speed and Reproducibility

The primary advantage of ATR is its speed, ease of use, and high reproducibility. The effective pathlength of the measurement is determined by the properties of the crystal and the wavelength of light, not by the thickness of a pellet you pressed. This consistency makes it ideal for quality control and high-throughput applications.

The ATR Disadvantage: Potential for Spectral Differences

Because the penetration depth of the evanescent wave is dependent on wavelength, ATR spectra can look slightly different from transmission (KBr) spectra. Specifically, peaks at lower wavenumbers may appear relatively more intense. While modern software can often correct for this, direct comparison to older, KBr-based spectral libraries can sometimes be challenging.

Choosing the Right Method for Your Analysis

Select your technique based on your specific analytical needs, not on convention alone.

- If your primary focus is speed and ease-of-use for routine analysis: ATR is the clear choice for its minimal sample prep and high throughput.

- If you are analyzing liquids, pastes, or aqueous solutions: ATR is your only viable option, as the KBr salt would dissolve.

- If you must analyze the bulk composition of a solid and not just its surface: The KBr method is more suitable, as it involves grinding and homogenizing the sample material.

- If your sample is a dark, highly absorbing material (like a carbon-filled polymer): ATR is often superior, as making a transmissive KBr pellet thin enough to allow any light through can be nearly impossible.

Understanding this fundamental difference between a transmission measurement and a surface reflectance measurement empowers you to select the precise tool for your analytical challenge.

Summary Table:

| Feature | KBr (Transmission) | ATR (Reflectance) |

|---|---|---|

| Core Principle | IR light passes through a diluted sample pellet | IR light reflects off the surface of a neat sample |

| Sample Prep | Labor-intensive, destructive grinding and pressing | Fast, non-destructive; place sample on crystal |

| Ideal For | Bulk analysis of dry, solid powders | Surface analysis of solids, liquids, pastes, aqueous solutions |

| Key Advantage | Represents bulk composition | Speed, simplicity, versatility |

| Key Limitation | Hygroscopic; not for wet/aqueous samples | Surface-sensitive; spectral differences vs. KBr |

Optimize Your FTIR Analysis with KINTEK

Choosing between KBr and ATR is critical for accurate results. KINTEK specializes in providing the right lab equipment and consumables to support both techniques, ensuring your laboratory operates at peak efficiency.

We provide the tools you need to succeed:

- For KBr Analysis: High-quality KBr powder and reliable hydraulic presses for creating perfect pellets.

- For ATR Analysis: Durable ATR accessories with robust diamond or germanium crystals for fast, reproducible surface measurements.

Let our expertise guide you to the optimal solution for your specific samples and analytical goals. Contact our team today to discuss your FTIR requirements and discover how we can enhance your lab's capabilities.

Visual Guide

Related Products

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the role of a laboratory hydraulic press in the preparation of LiTa2PO8 (LTPO) ceramic pellets? | KINTEK

- What are the most common causes of hydraulic system failure? Prevent Downtime and Costly Repairs

- What is the compression method of processing plastic? A Guide to Strong, Cost-Effective Molding

- How do you press wood pellets? Master the Process of High-Pressure Pelletizing

- What is the application of a laboratory hydraulic press in PHA testing? Perfecting Biopolymer Material Analysis

- What is a 100 ton hydraulic press? Harnessing Immense Force for Industrial Applications

- What is a recessed plate filter press? Achieve Maximum Dewatering for Solid-Liquid Separation

- What are hydraulic presses used for? Powering Industries with Immense, Controlled Force