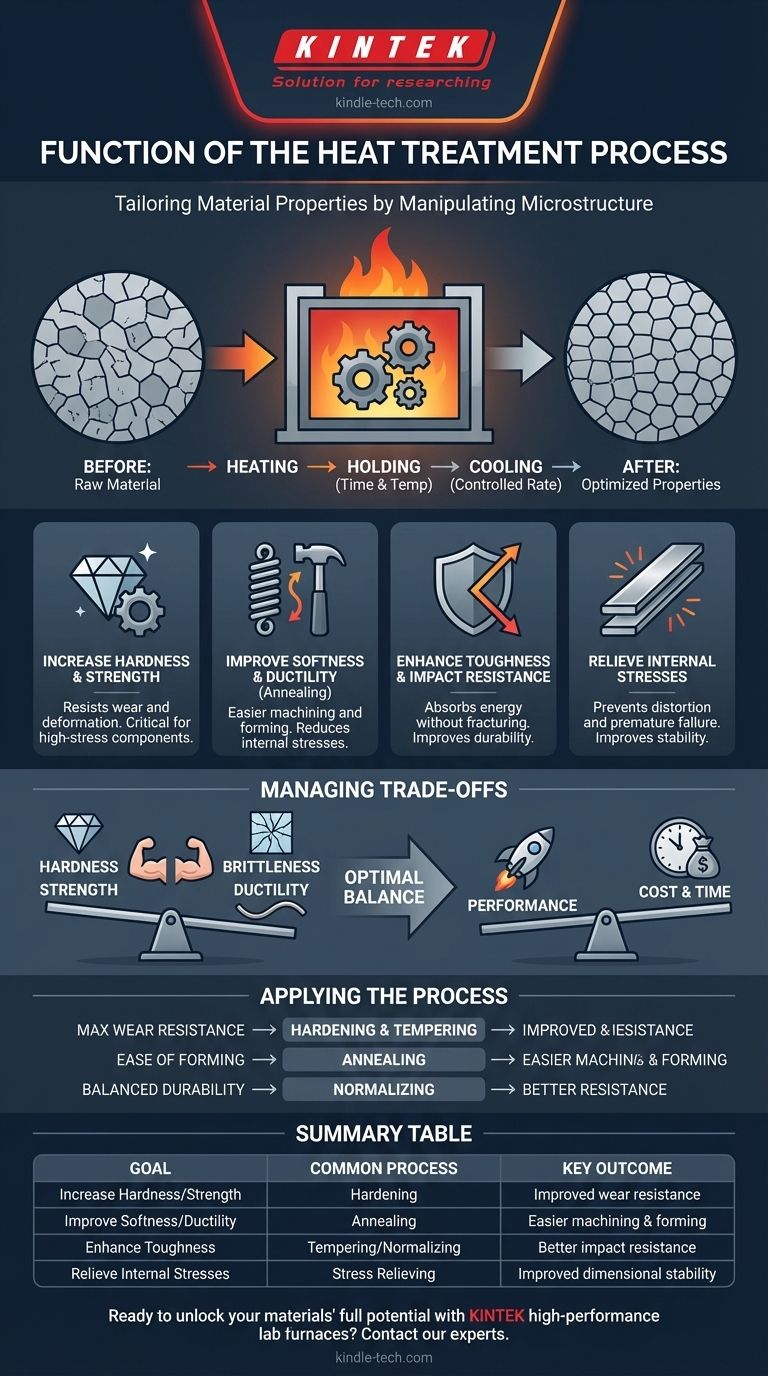

At its core, heat treatment is a highly controlled manufacturing process that uses heating and cooling to deliberately alter the physical and mechanical properties of a material, most often a metal. Its function is not to change the shape of the part, but to modify its internal microstructure. This allows engineers to make a material harder, stronger, and more resistant to wear, or conversely, softer and more ductile, to precisely match the demands of a specific application.

Heat treatment should be viewed as the process of tailoring a material's properties. It allows you to resolve inherent conflicts—such as the trade-off between hardness and brittleness—to achieve an optimal balance of characteristics that a raw material does not possess on its own.

The Core Principle: Manipulating Microstructure

Heat treatment works by changing the internal crystal structure of a metal, known as its microstructure. This internal architecture is what ultimately dictates the material's mechanical properties.

The Mechanism of Change

The process involves three fundamental stages: heating the material to a specific temperature, holding it at that temperature for a set duration, and then cooling it at a controlled rate. The precise temperatures, times, and cooling rates determine the final outcome.

Altering Grain Size and Phase

By controlling the heating and cooling cycle, you can change the size, shape, and distribution of the microscopic grains within the metal. This manipulation can also trigger phase transformations, where the crystal structure itself rearranges into a new form with entirely different properties.

Primary Goals of Heat Treatment

While there are many specific heat treatment processes, they all serve one or more of a few key objectives. Understanding these goals is essential to understanding the "why" behind the process.

Increasing Hardness and Strength

One of the most common goals is to make a material harder and stronger. This enhances its resistance to wear, abrasion, and deformation. This is critical for components like gears, bearings, and cutting tools that are subjected to intense contact stresses.

Improving Softness and Ductility (Annealing)

Conversely, heat treatment can be used to make a material softer and more ductile (the ability to be shaped without fracturing). This process, known as annealing, reduces internal stresses and makes the metal easier to machine, form, or stamp.

Enhancing Toughness and Impact Resistance

Toughness is a material's ability to absorb energy and resist fracturing under impact. It is distinct from hardness. Processes like normalizing and tempering are used to refine the grain structure and increase the toughness of steel, making it more durable and less likely to fail suddenly.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or heavy machining can introduce significant internal stresses into a part. If not relieved, these stresses can lead to distortion or premature failure. Heat treatment provides a controlled way to relax these stresses, improving the part's stability and service life.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a discipline of managing compromises. Every change in a property comes with a corresponding trade-off that must be understood and managed.

Hardness vs. Brittleness

This is the most fundamental trade-off. As you increase a metal's hardness, you almost always increase its brittleness, making it more susceptible to shattering under impact. A process like tempering is specifically designed to be performed after hardening to reduce brittleness and restore some toughness, albeit at the cost of a slight reduction in peak hardness.

Strength vs. Ductility

Increasing a material's strength often reduces its ductility. A very strong part may not be able to bend or deform plastically, making it unsuitable for applications that require some flexibility. Annealing reverses this, increasing ductility at the expense of strength.

Performance vs. Cost

Heat treatment adds time, energy consumption, and complexity to the manufacturing cycle. The decision to heat treat is an economic one, balancing the need for enhanced material properties against the added production cost. It is only employed when the performance requirements of the final part justify the investment.

Applying This to Your Goal

The specific heat treatment process you choose depends entirely on your end goal for the material.

- If your primary focus is maximum wear resistance and surface hardness: You will use hardening processes, but must follow them with tempering to mitigate the resulting brittleness.

- If your primary focus is ease of manufacturing and formability: Annealing is the correct choice to soften the material, improve ductility, and relieve internal stresses before machining or shaping.

- If your primary focus is a balanced, durable part for general service: Normalizing is often used to create a uniform and tough microstructure, or a hardening and tempering combination will be used to achieve a precise balance of strength and toughness.

Ultimately, heat treatment is the essential step that unlocks a material's full engineering potential, transforming a standard metal into a high-performance component.

Summary Table:

| Goal | Common Process | Key Outcome |

|---|---|---|

| Increase Hardness/Strength | Hardening | Improved wear resistance |

| Improve Softness/Ductility | Annealing | Easier machining & forming |

| Enhance Toughness | Tempering/Normalizing | Better impact resistance |

| Relieve Internal Stresses | Stress Relieving | Improved dimensional stability |

Ready to unlock the full potential of your materials? The precise control required for effective heat treatment starts with reliable equipment. KINTEK specializes in high-performance lab furnaces and ovens designed for consistent, repeatable results. Whether you're annealing, hardening, or tempering, our solutions help you achieve the exact material properties your application demands. Contact our experts today to find the perfect heat treatment solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is vacuum annealing process? Achieve Pristine, Oxidation-Free Metal Treatment

- What is the purpose of vacuum hardening? Achieve Flawless, High-Strength Metal Components

- How does quenching work chemistry? Mastering the Atomic Race for Harder Steel

- What is the lowest possible vacuum pressure? Achieve Pristine Conditions for Your Lab

- What is the application of furnace brazing? Achieve Strong, Complex, and Clean Assemblies

- What does heat treatment do to microstructure properties? Tailor Material Strength, Hardness, and Toughness

- What is the primary function of high-temperature furnaces in mechanical characterization? Simulating Extreme Reality

- What is the primary function of a molten salt reaction furnace? Enhance Carbon-Carbon Composite Surface Modification