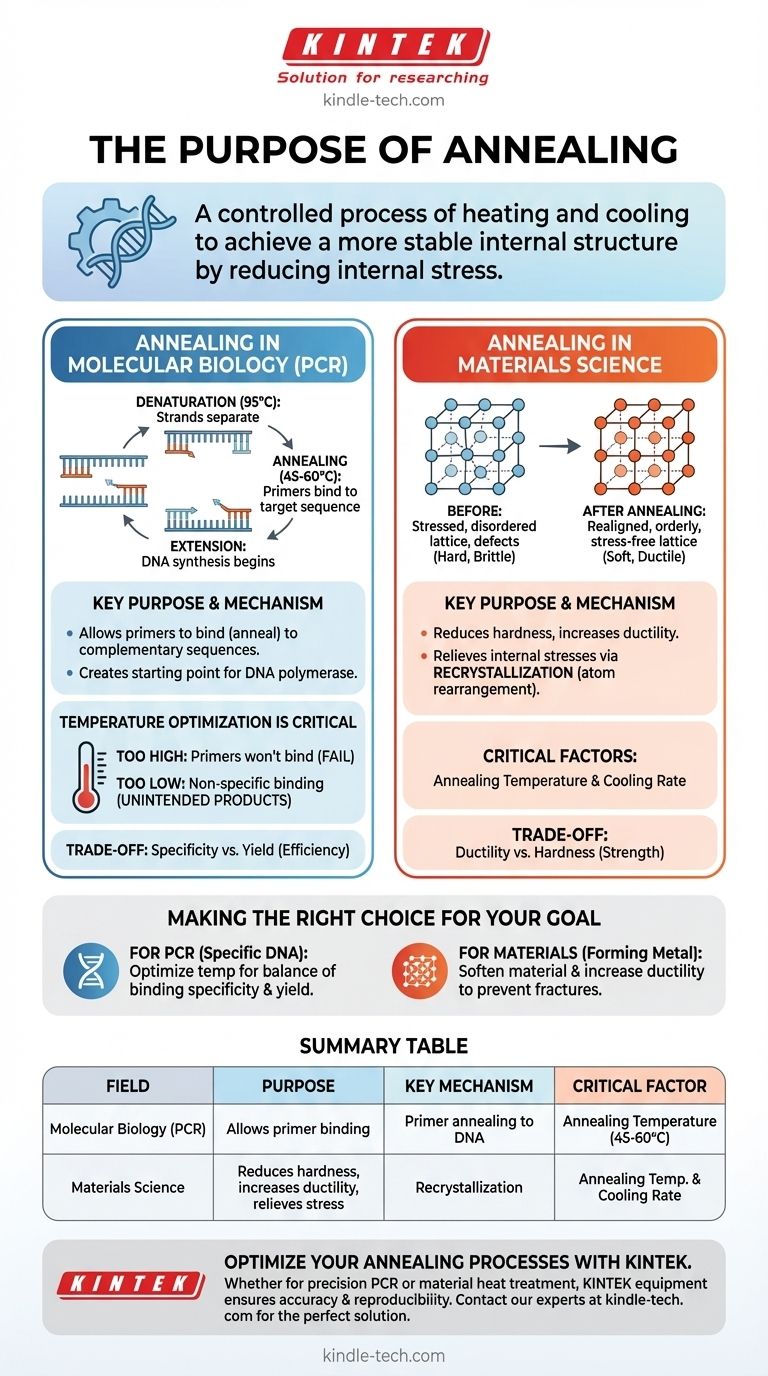

In practice, annealing refers to a controlled process of heating and cooling used to achieve a more stable internal structure. Depending on the context, this term describes a critical step in either molecular biology—specifically for DNA amplification—or in materials science for altering the properties of metals and other materials.

At its core, annealing is a process that reduces internal stress and enables components to organize themselves correctly. For DNA, this means primers binding to their target sequence. For a metal, it means atoms realigning into a less strained crystal structure.

Annealing in Molecular Biology (PCR)

In the context of biology, annealing is a fundamental step in the Polymerase Chain Reaction (PCR), a technique used to amplify a specific segment of DNA. The PCR cycle consists of three main stages: denaturation, annealing, and extension.

The Role of Annealing in the PCR Cycle

The annealing step occurs after the denaturation step, where high heat (e.g., 95°C) separates the two strands of the DNA double helix.

Once the strands are separated, the temperature is lowered to the annealing temperature (typically 45–60°C). This allows the next stage, extension, to begin.

The Mechanism: Binding Primers to DNA

The primary purpose of this step is to allow short, single-stranded DNA sequences called primers to bind (or "anneal") to their complementary sequences on the single-stranded DNA templates.

These primers are designed to bracket the specific DNA region of interest. Their binding creates the starting point for the DNA polymerase enzyme to begin copying the DNA in the subsequent extension step.

Why Temperature is Critical

The annealing temperature is the most crucial variable for the success and specificity of a PCR experiment.

If the temperature is too high, the primers will not bind to the template DNA, and the reaction will fail. If the temperature is too low, primers may bind non-specifically to incorrect sections of the DNA, leading to the amplification of unintended products.

Annealing in Materials Science

In materials science and metallurgy, annealing is a heat treatment process that changes a material's physical and sometimes chemical properties.

The Goal: Soften and Relieve Stress

The primary purpose of annealing a material, such as a metal, is to reduce its hardness and increase its ductility (its ability to be drawn out or deformed without breaking).

This is achieved by relieving the internal stresses that may have built up during prior work, such as bending, rolling, or machining. A less stressed material is more homogeneous and less prone to cracking or failure.

The Mechanism: Recrystallization

When a material is heated to its annealing temperature, the atoms are given enough energy to migrate within the crystal lattice. This allows them to rearrange into a more orderly, stress-free configuration.

This process, known as recrystallization, eliminates the defects and dislocations that make a material hard and brittle. A slow cooling rate is essential to ensure the atoms settle into this new, relaxed state without locking new stress in.

Understanding the Trade-offs

Whether in a test tube or a furnace, the annealing process involves a fundamental balance of opposing factors.

Specificity vs. Yield in PCR

In PCR, the main trade-off is between the specificity of primer binding and the efficiency (or yield) of the reaction. A higher annealing temperature increases specificity but may reduce the overall amount of DNA amplified. A lower temperature can increase yield but risks creating unwanted, non-specific products.

Ductility vs. Hardness in Materials

In materials, the trade-off is between workability and strength. Annealing makes a metal softer and more ductile, which is ideal for shaping, stamping, or machining. However, this process inherently reduces the material's hardness and tensile strength, which might be undesirable for the final product.

Making the Right Choice for Your Goal

Your application determines how you should approach the annealing process.

- If your primary focus is amplifying a specific DNA sequence: Optimize your annealing temperature to be high enough for specific primer binding while still being low enough to ensure an efficient reaction yield.

- If your primary focus is preparing a metal for forming: Use annealing to soften the material and increase its ductility, making it easier to work with and preventing fractures during processing.

- If your primary focus is creating a strong, finished part: Recognize that annealing may be an intermediate step to relieve stress, but a different heat treatment (like quenching and tempering) may be required afterward to achieve the final desired hardness and strength.

Ultimately, annealing is a powerful tool for achieving a stable and organized state by carefully managing temperature and time.

Summary Table:

| Field | Purpose of Annealing | Key Mechanism | Critical Factor |

|---|---|---|---|

| Molecular Biology (PCR) | Allows primers to bind to target DNA sequence | Primer binding to single-stranded DNA template | Annealing Temperature (45-60°C) |

| Materials Science | Reduces hardness, increases ductility, relieves internal stress | Recrystallization (atom realignment) | Annealing Temperature & Cooling Rate |

Optimize Your Annealing Processes with KINTEK

Whether you are amplifying DNA with precision PCR equipment or require reliable furnaces for material heat treatment, KINTEK's specialized lab equipment is designed for accuracy and reproducibility. Our products help you master critical temperature-dependent steps, ensuring optimal results for your specific application.

Contact our experts today to find the perfect solution for your laboratory's annealing needs and enhance your research or production outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing