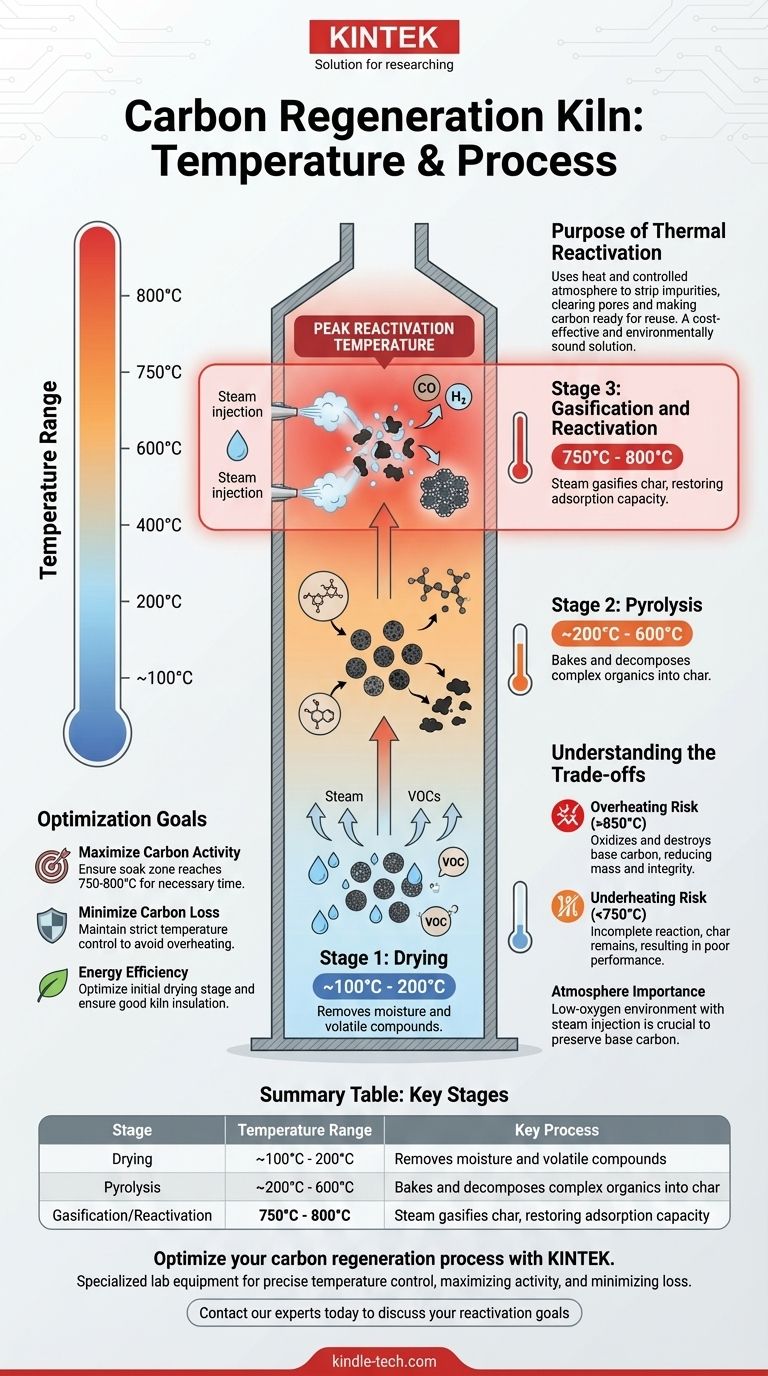

In practice, a carbon regeneration kiln operates across a range of temperatures, typically reaching a peak reactivation temperature between 750°C and 800°C (1382°F to 1472°F). This is not a single setting, but a carefully controlled thermal process with distinct stages designed to remove adsorbed impurities without destroying the carbon itself.

The core principle of carbon regeneration is not simply heating, but using a precise temperature profile to drive a sequence of reactions. The final, highest temperature stage uses steam to gasify and remove stubborn residues, which is what restores the carbon's valuable adsorptive capacity.

The Purpose of Thermal Reactivation

Activated carbon works by adsorbing impurities onto its vast internal pore structure. Over time, these pores become saturated, and the carbon loses its effectiveness.

The goal of a regeneration kiln is to use heat and a controlled atmosphere to strip these impurities away, clearing the pores and making the carbon ready for reuse. This is a far more cost-effective and environmentally sound solution than discarding and replacing the saturated carbon.

The Key Stages Inside the Kiln

The journey of carbon through a regeneration kiln is a multi-step process, with each temperature zone serving a specific purpose. The process generally moves from lower to higher temperatures.

Stage 1: Drying (~100°C - 200°C)

The first step is to remove water and moisture that the carbon has absorbed. This low-temperature heating also drives off the most volatile organic compounds that were adsorbed during service.

Stage 2: Pyrolysis (~200°C - 600°C)

As the temperature rises further, the more complex organic compounds that are strongly adsorbed onto the carbon begin to decompose. This process, known as pyrolysis or baking, breaks them down into a residual char of elemental carbon that remains within the pore structure.

Stage 3: Gasification and Reactivation (750°C - 800°C)

This is the most critical and highest-temperature phase. In this "soak zone," steam (water vapor) is injected into the kiln. At these elevated temperatures, the steam triggers a controlled chemical reaction with the char residue left behind from pyrolysis.

This reaction gasifies the unwanted char, converting it into carbon monoxide and hydrogen gas, which then exit the kiln. This step effectively cleans out the micropores, restoring the carbon's original adsorptive properties.

Understanding the Trade-offs

Achieving effective regeneration requires a delicate balance. The success of the entire process hinges on precise control over temperature and atmosphere.

The Risk of Overheating

If the temperature exceeds the optimal range (e.g., above 850°C), the steam and heat will begin to react with the activated carbon structure itself, not just the adsorbed residue. This oxidizes and destroys the base carbon, reducing its mass and structural integrity, leading to significant carbon loss and higher operational costs.

The Problem of Underheating

If the kiln does not reach the necessary gasification temperature (around 750°C), the reaction with steam will be incomplete. The pyrolytic char will remain in the pores, blocking active sites. The carbon will not be fully regenerated, resulting in poor performance when it is put back into service.

The Importance of the Atmosphere

Simply heating the carbon in the presence of air (oxygen) would cause it to burn away completely. The process relies on a low-oxygen environment and the controlled injection of steam to ensure only the unwanted residue is gasified while the valuable activated carbon structure is preserved.

Making the Right Choice for Your Goal

To optimize your regeneration process, you must align your operating parameters with your primary objective.

- If your primary focus is maximizing carbon activity: Ensure the soak zone consistently reaches the target gasification temperature (750°C - 800°C) for the necessary residence time.

- If your primary focus is minimizing carbon loss: Maintain strict temperature control to avoid overheating, as even small excursions above the target can significantly increase the oxidation of the base carbon.

- If your primary focus is energy efficiency: Optimize the initial drying stage, as removing water is the most energy-intensive part of the process, and ensure the kiln is well-insulated to maintain thermal stability.

Mastering the distinct temperature stages of regeneration is the key to restoring carbon performance while maximizing its operational lifespan.

Summary Table:

| Stage | Temperature Range | Key Process |

|---|---|---|

| Drying | ~100°C - 200°C | Removes moisture and volatile compounds |

| Pyrolysis | ~200°C - 600°C | Bakes and decomposes complex organics into char |

| Gasification/Reactivation | 750°C - 800°C | Steam gasifies char, restoring adsorption capacity |

Optimize your carbon regeneration process with KINTEK.

Our specialized lab equipment and consumables are designed to help you achieve precise temperature control, maximize carbon activity, and minimize loss. Whether you're focused on performance, efficiency, or extending carbon lifespan, KINTEK has the solutions for your laboratory's needs.

Contact our experts today to discuss how we can support your reactivation goals.

Visual Guide

Related Products

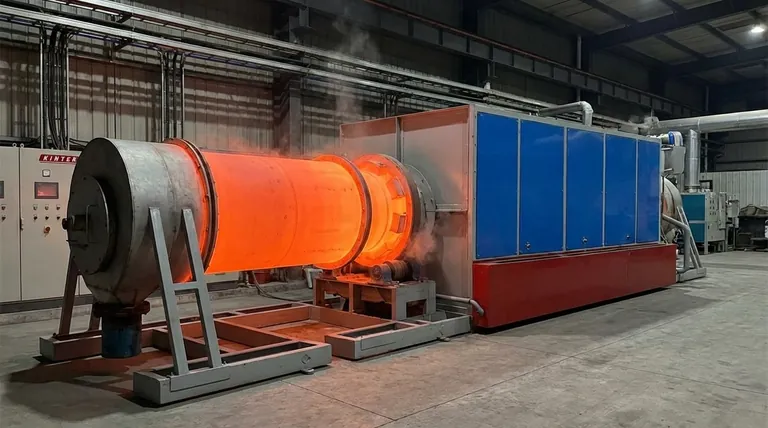

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Mesh belt controlled atmosphere furnace

People Also Ask

- Can you restore activated carbon? Understanding the Industrial Reactivation Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What temperature is a carbon regeneration kiln? Master the 650°C-800°C Range for Optimal Results

- How to regenerate activated carbon? Master the 3-Stage Thermal Process for Cost Savings

- How do you carbonize charcoal? Master the 3-Step Pyrolysis Process for High-Purity Carbon