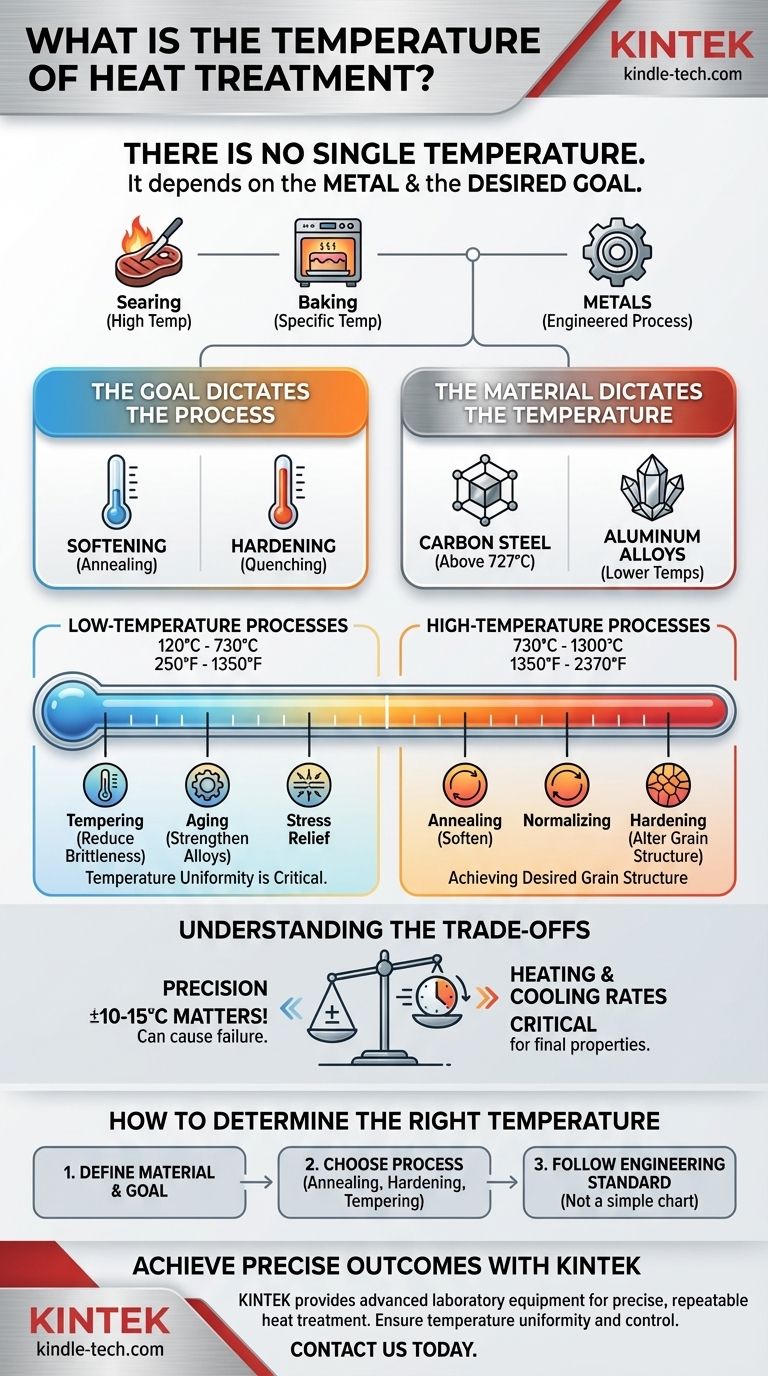

There is no single temperature for heat treatment. The correct temperature is entirely dependent on the specific metal being treated and the desired final properties, such as hardness, softness, or internal stress relief.

For instance, many common low-temperature vacuum processes operate between 175°C and 730°C (350-1350°F), but this represents only one category of heat treatment.

The core principle of heat treatment is not about hitting one magic number. It's a precise, engineered process where the temperature, time, and cooling rate are all carefully controlled to intentionally alter a metal's internal microstructure to achieve a specific engineering goal.

Why There Is No Single 'Heat Treatment' Temperature

Asking for "the" temperature of heat treatment is like asking for "the" temperature of cooking. Searing a steak and baking a cake are both "cooking," but they require vastly different temperatures and methods to achieve the desired result. The same is true for metals.

The Goal Dictates the Process

The purpose of the treatment determines the required temperature. A process designed to soften a metal (annealing) will use a very different temperature profile than one designed to make it extremely hard (quenching and tempering).

The Material Dictates the Temperature

Every metal alloy has unique critical temperatures at which its internal crystal structure transforms. For carbon steel, these critical changes happen above 727°C (1340°F), while aluminum alloys are treated at much lower temperatures. The process must be tailored to the specific material's metallurgy.

Common Temperature Ranges and Their Purpose

While there's no single temperature, we can group processes into general ranges to understand their function.

Low-Temperature Processes (approx. 120°C - 730°C)

This range, often performed in vacuum furnaces, is primarily used for modifying properties after a primary hardening treatment or for stress relief.

Processes include tempering, which reduces brittleness in hardened steel, and aging, which strengthens certain aluminum or specialty alloys. The excellent temperature uniformity in modern furnaces is critical for these processes to ensure consistent properties throughout the component.

High-Temperature Processes (approx. 730°C - 1300°C)

This range is where the fundamental crystal structure of steels is altered.

Processes like annealing, normalizing, and hardening all require heating steel above its critical transformation point to achieve the desired grain structure before cooling it in a controlled manner.

Understanding the Trade-offs

Choosing the right temperature is a balancing act. A minor deviation can lead to a failed component.

Precision vs. Outcome

A difference of just 10-15 degrees can be the difference between a perfectly hardened part and one that is too brittle or too soft. This is why precise control and temperature uniformity across the entire part are non-negotiable in professional heat treatment.

Heating and Cooling Rates Matter

The peak temperature is only one part of the equation. The speed at which you heat the metal (heating rate) and, more importantly, the speed at which you cool it (cooling rate) are just as critical in determining the final microstructure and properties of the material.

How to Determine the Right Temperature

To find the correct temperature, you must first define your material and your goal.

- If your primary focus is to soften steel or relieve internal stress: You need an annealing or stress-relieving process, which requires specific high-temperature soaks determined by the exact steel alloy.

- If your primary focus is to harden a steel component: You must heat it above its critical "austenitizing" temperature (often >800°C) and then cool it rapidly in a process called quenching.

- If your primary focus is to reduce the brittleness of a hardened part: You need a lower-temperature tempering process, where the specific temperature directly controls the final balance of hardness and toughness.

Ultimately, the correct heat treatment temperature is not found in a simple chart but is specified by an engineering or metallurgical standard for your specific material and application.

Summary Table:

| Process Goal | Typical Temperature Range | Common Applications |

|---|---|---|

| Low-Temp (Stress Relief, Tempering) | 120°C - 730°C (250°F - 1350°F) | Reducing brittleness, stress relief in hardened steels |

| High-Temp (Annealing, Hardening) | 730°C - 1300°C (1350°F - 2370°F) | Softening steel, altering grain structure for hardening |

| Aging (Precipitation Hardening) | 120°C - 250°C (250°F - 480°F) | Strengthening aluminum and specialty alloys |

Achieve Precise Metallurgical Outcomes with KINTEK

Choosing the right heat treatment temperature is critical for achieving the exact material properties your application requires. Minor temperature deviations of just 10-15°C can mean the difference between a perfectly hardened component and a failed part.

KINTEK specializes in providing the advanced laboratory equipment and consumables needed for precise, repeatable heat treatment processes. Whether you're working with steel, aluminum, or specialty alloys, our solutions ensure the temperature uniformity and control necessary for consistent results.

Let our experts help you select the right equipment for your specific metallurgical goals. Contact KINTEK today to discuss your laboratory's heat treatment needs and discover how we can enhance your process reliability and outcomes.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance

- How is ash content determined using muffle furnace? Achieve Accurate Mineral Analysis

- What is the burning temperature of a furnace? From 200°C to 3000°C, It Depends on Your Needs

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing

- What are the different types of ash analysis? Dry vs. Wet Ashing Methods Explained