At its core, a burnout furnace is a specialized high-temperature oven used to completely vaporize or "burn out" a disposable pattern, typically made of wax or resin, from an investment mold. This process leaves behind a perfectly clean, empty cavity, which is then filled with molten material (like metal or glass) to create a precise casting. It is an essential tool in fields like dentistry, jewelry making, and industrial prototyping.

A burnout furnace is not simply a device for heating; it is a precision instrument designed to execute a controlled, multi-stage heating process. Its primary purpose is to ensure the complete and clean removal of a pattern from a mold without damaging the mold itself, paving the way for a flawless final product.

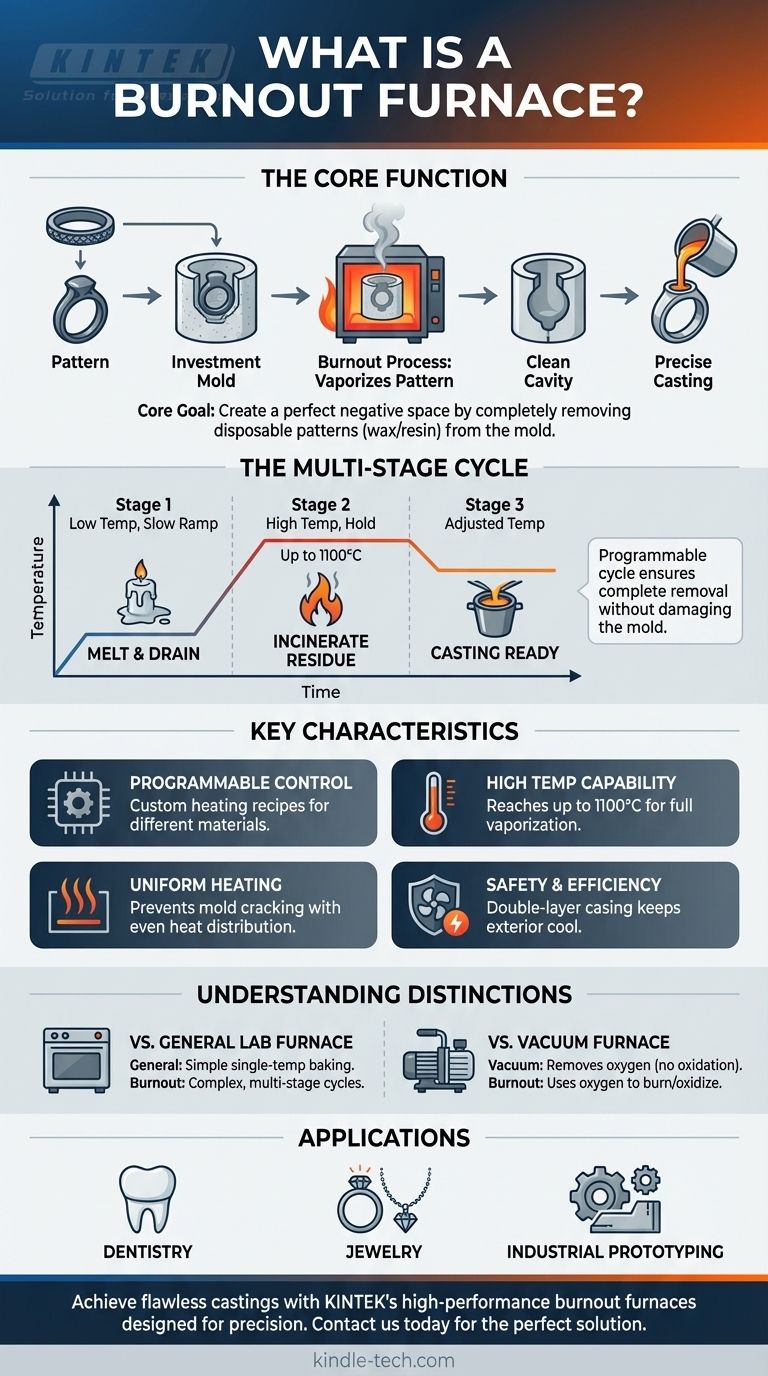

The Core Function: Preparing a Mold for Casting

The burnout process is a critical step in investment casting, also known as the "lost-wax" or "lost-resin" method. The furnace's role is to manage this delicate transformation with absolute precision.

Creating the Negative Space

The entire goal of the burnout cycle is to create a perfect negative space. A pattern (e.g., a wax model of a ring or a 3D-printed resin dental crown) is encased in a ceramic-like material called investment. Once the investment hardens, the furnace takes over.

The Burnout Cycle

A burnout furnace does not just heat to a single temperature. It follows a programmable cycle with multiple stages.

First, a slow, low-temperature ramp melts the bulk of the pattern material, allowing it to drain out. Then, the temperature is increased and held for a period to completely incinerate and vaporize any remaining residue. Finally, the temperature is adjusted to the ideal level for receiving the molten metal for casting.

Why Precision is Critical

If heating is too fast, the expanding pattern can crack the investment mold, ruining the cast. If the temperature doesn't get high enough or isn't held for long enough, a microscopic layer of carbon residue can remain, leading to surface defects in the final product.

Key Characteristics of a Burnout Furnace

Specific design features enable the furnace to perform its function reliably and safely. These characteristics distinguish it from a general-purpose laboratory oven.

Programmable Temperature Control

This is the most crucial feature. Modern burnout furnaces can have dozens of programmable segments, allowing technicians to create custom heating "recipes" for different pattern materials (wax vs. resin) and investment types. This ensures optimal results every time.

High Temperature Capability

Burnout furnaces must reach temperatures high enough to fully vaporize all residual material, typically operating up to 1100°C (2012°F). This also allows the mold to be brought to the correct temperature for casting, which prevents the molten metal from cooling too quickly.

Rapid and Uniform Heating

The furnace chamber, often made of ceramic fiber, is designed for rapid and even heat distribution. A uniform temperature field throughout the chamber is vital to prevent thermal stress that could crack the mold.

Safety and Efficiency

Modern designs feature a double-layer steel casing with fan cooling. This keeps the exterior surface of the furnace at a safe temperature (often below 50°C) for the operator, even when the interior is at its maximum heat.

Understanding the Distinctions

It's common to see different types of furnaces discussed together, but their applications are fundamentally different. Understanding these differences is key to selecting the right equipment.

Burnout Furnace vs. General Lab Furnace

A burnout furnace is a highly specialized type of lab furnace. While a general furnace may be used for simple drying or baking at a single temperature, a burnout furnace is engineered for the complex, multi-stage programmable cycles required for casting.

Burnout Furnace vs. Vacuum Furnace

This is a critical distinction. A burnout furnace operates in a normal atmosphere, using oxygen to burn and oxidize the pattern material away.

A vacuum furnace, by contrast, removes the atmosphere to create a clean, oxygen-free environment. It is used for processes like brazing, sintering, or heat-treating metals where oxidation would be detrimental to the material's properties. The two serve nearly opposite purposes.

Making the Right Choice for Your Process

The specific application dictates which features of a burnout furnace are most important.

- If your primary focus is dental or jewelry casting: You need a furnace with highly precise, repeatable programmable controls to handle delicate patterns and achieve flawless surface finishes.

- If your primary focus is industrial prototyping: The ability to create custom programs for new 3D-printed resins and the furnace's chamber size will be your most important considerations.

- If your primary focus is general laboratory heating: A dedicated burnout furnace is likely unnecessary unless your work specifically requires its precise, multi-stage heating capabilities for processes like curing or ashing.

Ultimately, a burnout furnace is a specialized tool engineered to transform a pattern into a perfect, empty mold, setting the stage for a successful casting.

Summary Table:

| Key Feature | Purpose |

|---|---|

| Programmable Temperature Control | Executes multi-stage heating cycles for different materials |

| High Temperature Capability (up to 1100°C) | Ensures complete vaporization of pattern residues |

| Uniform Heating Chamber | Prevents mold cracking and ensures consistent results |

| Safe Double-Layer Casing | Protects operators during high-temperature operation |

Ready to achieve flawless castings in your lab? KINTEK specializes in high-performance burnout furnaces designed for precision and reliability in dentistry, jewelry making, and industrial prototyping. Our equipment ensures complete, clean mold preparation with programmable cycles and uniform heating. Contact us today to find the perfect burnout furnace for your specific needs!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between sintering and vitrification? Key Thermal Process Distinctions

- What are the methods of ash analysis? Dry Ashing, Wet Ashing, and More Explained

- What is sinter used for? Unlocking the Power of Fusing Materials Without Melting

- What are the primary functions of a muffle furnace for Inconel 718? Achieve Uniform Annealing and Stress Relief

- What is the function of a high-temperature muffle furnace in YAG synthesis? Master Pure-Phase Crystal Production

- What is the inside material of the muffle furnace? Discover the Refractory Core for High-Temp Precision

- How do you check the temperature of a muffle furnace? A Guide to Precise Monitoring

- What is the difference between oven incubator and muffle furnace? Choose the Right Lab Heating Tool