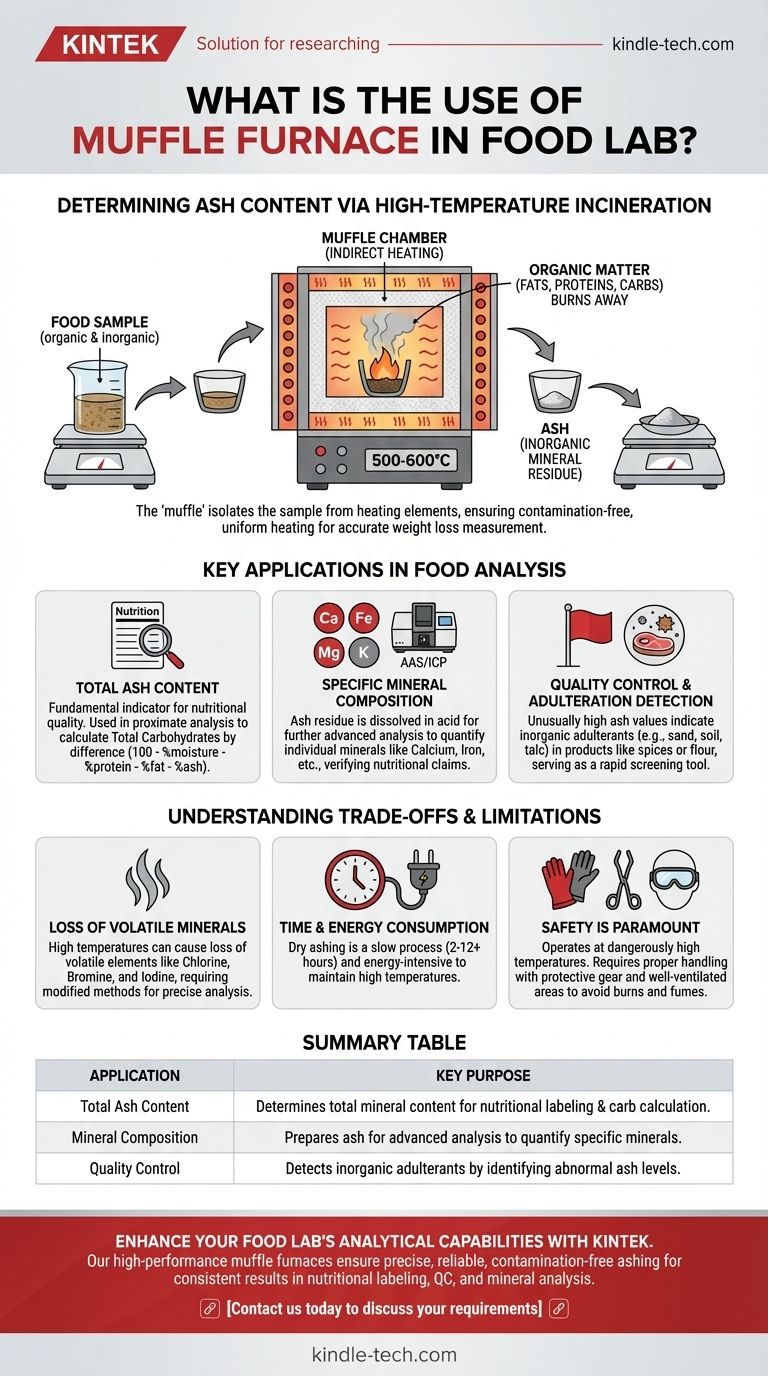

In a food laboratory, the muffle furnace is the primary instrument for determining the ash content of a food sample. This process, known as incineration or "ashing," involves heating a sample at extremely high temperatures (typically 500-600°C) to burn away all organic matter, such as fats, proteins, and carbohydrates. What remains is the ash—the inorganic, non-combustible mineral residue—which is crucial for nutritional analysis and quality control.

To truly understand a food's composition, you must separate its organic and inorganic components. A muffle furnace accomplishes this fundamental task by using controlled, high heat to incinerate all organic material, leaving behind only the mineral ash for measurement and analysis.

The Core Principle: High-Temperature Incineration

A muffle furnace is not just a high-temperature oven; its design is critical for analytical work. It provides a controlled environment for the complete combustion of a sample.

How a Muffle Furnace Works

The term "muffle" refers to the insulated inner chamber that separates the sample from the direct heating elements. This design ensures that the sample is heated uniformly through convection and radiation, not by direct flame contact.

This isolation is critical. It prevents contamination from the heating elements and ensures that the loss in weight is due only to the combustion of the sample's organic components.

The Standard Ashing Process

The procedure is straightforward but precise. First, a food sample is carefully weighed into a pre-weighed, heat-proof crucible. The crucible is then placed in the muffle furnace.

The furnace is slowly heated to a high temperature, usually between 550°C and 600°C, and held there for several hours. This process completely burns away all organic material, leaving only the inorganic minerals behind as a grayish-white ash. After cooling, the crucible is weighed again, and the ash content is calculated as a percentage of the original sample weight.

Key Applications in Food Analysis

The ash value is a fundamental data point in food science. It is not just one measurement but the gateway to several critical insights about a food product's quality, safety, and nutritional value.

Determining Total Ash Content

This is the most common application. Total ash content is a direct measure of the total amount of minerals present in a food.

On a nutritional label, this figure is used in the "proximate analysis" to calculate total carbohydrates by difference (100 - %moisture - %protein - %fat - %ash = %carbohydrate). It is a fundamental indicator of nutritional quality.

Analyzing Specific Mineral Composition

The ash obtained from the furnace is often just the first step. This mineral residue can then be dissolved in acid and analyzed using more advanced techniques, such as Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP).

This subsequent analysis reveals the precise amounts of individual minerals like calcium, magnesium, iron, and potassium. This is essential for verifying nutritional claims like "good source of calcium."

A Tool for Quality Control

The ash content of a pure food product is typically very consistent. An unusually high ash value can indicate the presence of inorganic adulterants, such as soil, sand, or talc, which may have been added fraudulently to increase weight.

For example, a high ash content in spices or flour is a common red flag for contamination or adulteration.

Understanding the Trade-offs and Limitations

While essential, the muffle furnace technique has limitations that every analyst must understand to interpret results correctly.

Loss of Volatile Minerals

The extremely high temperatures used in ashing can cause some minerals to vaporize and be lost. Elements like chlorine, bromine, and iodine are particularly volatile and may not be fully accounted for in the final ash weight.

For precise analysis of these specific elements, alternative methods or modified ashing procedures (e.g., adding fixing agents) may be required.

Time and Energy Consumption

Dry ashing in a muffle furnace is a slow process, often requiring 2 to 12 hours or even longer for a complete burn. The furnaces are also energy-intensive, consuming a significant amount of electricity to maintain high temperatures.

Safety is Paramount

Muffle furnaces operate at dangerously high temperatures. Proper handling procedures, including the use of long tongs, heat-resistant gloves, and protective eyewear, are non-negotiable to prevent severe burns. The furnace must also be operated in a well-ventilated area to safely dissipate fumes.

Making the Right Choice for Your Goal

Using a muffle furnace is about more than just getting a number; it's about answering a specific question about your food product.

- If your primary focus is nutritional labeling: Use the muffle furnace to determine the total ash content, a required component for calculating total carbohydrates and calories by difference.

- If your primary focus is food quality and safety: Analyze the ash percentage as a rapid screening tool to detect inorganic adulterants or confirm processing consistency.

- If your primary focus is making specific mineral claims: Use the furnace for the initial ashing step to prepare a clean mineral sample before proceeding to more advanced elemental analysis.

Mastering the use of the muffle furnace allows you to uncover the fundamental, inorganic foundation of any food product.

Summary Table:

| Application | Key Purpose |

|---|---|

| Total Ash Content | Determines total mineral content for nutritional labeling and carbohydrate calculation. |

| Mineral Composition | Prepares ash sample for advanced analysis (e.g., AAS, ICP) to quantify specific minerals like calcium or iron. |

| Quality Control | Detects inorganic adulterants (e.g., sand, talc) by identifying abnormal ash levels in products like spices or flour. |

Enhance Your Food Lab's Analytical Capabilities with KINTEK

Accurate ash content analysis is fundamental to food quality, safety, and compliance. KINTEK specializes in high-performance muffle furnaces designed for precise, reliable ashing processes in food laboratories. Our equipment ensures uniform heating and contamination-free results, helping you achieve consistent nutritional labeling, detect adulterants, and prepare samples for detailed mineral analysis.

Whether you're focused on proximate analysis, quality control, or verifying mineral claims, KINTEK provides the durable, energy-efficient lab equipment you need.

Contact us today to discuss your lab's requirements and discover how our solutions can support your food analysis goals.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the relationship between sintering temperature and melting temperature? Key Differences for Material Engineers

- What is the temperature of a muffle furnace? It's Not a Single Number—Find Your Perfect Range

- What is the temperature limit on a muffle furnace? A Guide to Selecting the Right Model

- How is a muffle furnace used for sample digestion? A Guide to Dry Ashing for Accurate Analysis

- How do you run a muffle furnace? Master the Step-by-Step Process for Safe, Precise Results