For high-temperature applications, the most common solution involves electric resistance heating elements made from specialized metallic alloys or ceramic composites. The specific material chosen is dictated primarily by the maximum required temperature and the chemical environment, or atmosphere, in which it will operate. Advanced processes may also utilize induction, arc, or radiant heating technologies for more specific goals.

The core challenge of high-temperature heating is not simply reaching a target temperature, but selecting a complete system—heating element, insulation, and atmosphere—that can reliably and efficiently sustain that temperature without degrading itself or the material being heated.

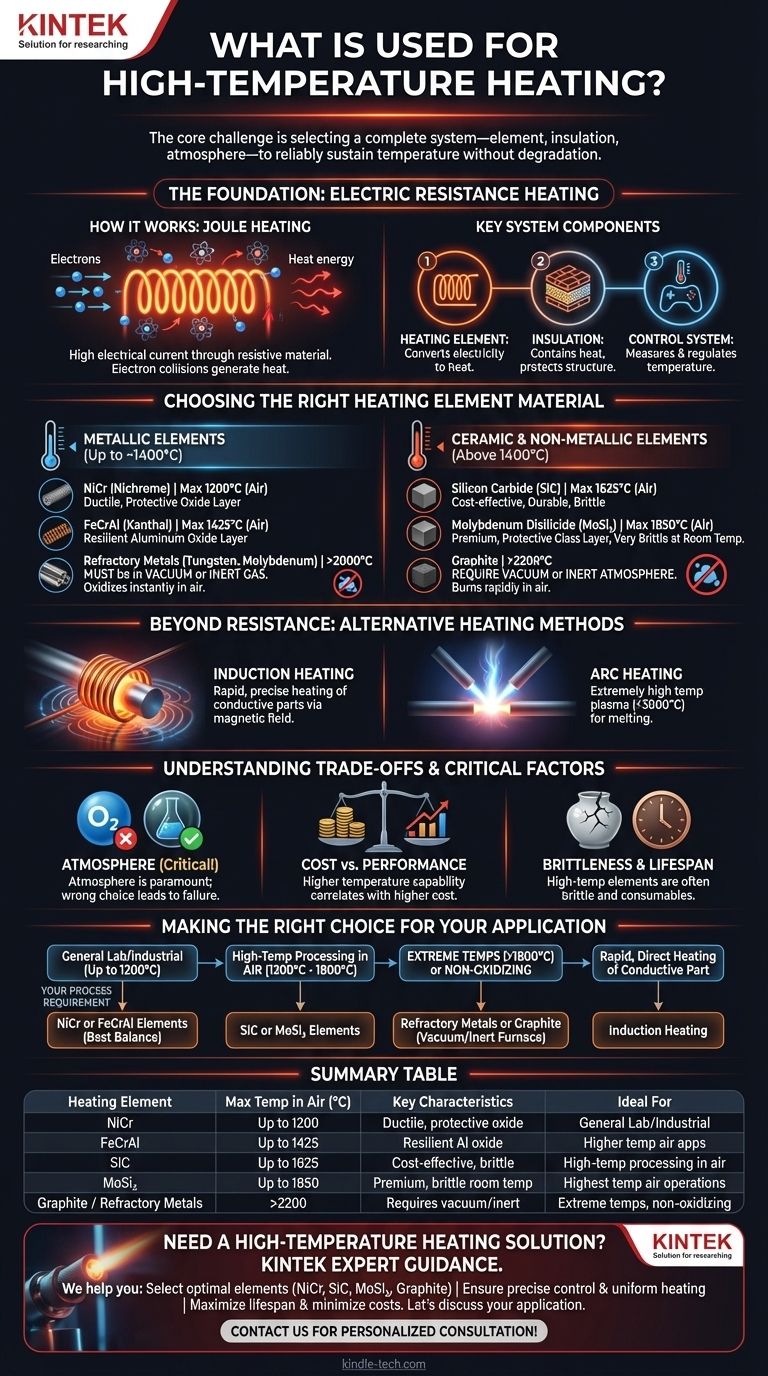

The Foundation: Electric Resistance Heating

Electric resistance is the most prevalent and straightforward method for generating high temperatures in furnaces and industrial equipment. It operates on a simple, reliable principle.

How It Works: The Principle of Joule Heating

This method passes a high electrical current through a material with moderate to high electrical resistance. As electrons are forced through the material, they collide with atoms, transferring their energy and generating heat. This effect is known as Joule heating.

The amount of heat generated is a function of the current and the material's resistance. This allows for precise temperature control by regulating the electrical power supplied to the system.

Key System Components

A high-temperature furnace is more than just its heating element. It is a system composed of three critical parts:

- The Heating Element: The material that converts electricity into heat.

- The Insulation: Refractory materials (like ceramic fiber or firebrick) that contain the heat and protect the furnace structure.

- The Control System: Thermocouples and controllers that measure the temperature and regulate power to maintain the setpoint.

Choosing the Right Heating Element Material

The heating element is the heart of the system. The material choice is the single most important factor determining a furnace's capabilities and limitations.

Metallic Elements (Up to ~1400°C)

Metallic elements are alloys designed to operate at high temperatures, typically in the presence of oxygen, without rapid degradation.

-

Nickel-Chromium (NiCr) alloys, often called Nichrome, are the workhorses for temperatures up to 1200°C (2200°F). They are ductile and form a stable, protective layer of chromium oxide on their surface.

-

Iron-Chromium-Aluminum (FeCrAl) alloys, often sold as Kanthal, can reach higher temperatures, up to 1425°C (2600°F). They form a very resilient aluminum oxide layer that protects the underlying metal.

-

Refractory Metals like Tungsten and Molybdenum can operate at extremely high temperatures (>2000°C). However, they oxidize instantly in air at these temperatures and must be used in a vacuum or inert gas atmosphere (like argon or nitrogen).

Ceramic & Non-Metallic Elements (Above 1400°C)

For temperatures beyond the limits of common alloys in air, ceramic or carbon-based elements are required.

-

Silicon Carbide (SiC) elements are a cost-effective choice for temperatures up to 1625°C (2950°F). They are hard and durable but can be brittle, requiring careful handling.

-

**Molybdenum Disilicide (MoSi₂) ** elements are the premium choice for very high-temperature air operation, capable of reaching 1850°C (3360°F). They form a protective layer of silica glass, but they are very brittle at room temperature.

-

Graphite can reach the highest temperatures of all, well over 2200°C (4000°F). Like refractory metals, it will rapidly burn away in the presence of oxygen and absolutely requires a vacuum or inert atmosphere.

Beyond Resistance: Alternative Heating Methods

For specialized applications, other technologies offer distinct advantages over standard resistance heating.

Induction Heating

Induction heating uses a powerful, high-frequency alternating magnetic field to induce electrical currents (eddy currents) directly within a conductive workpiece. This allows for extremely rapid, precise, and efficient heating of the part itself without heating the surrounding chamber.

Arc Heating

An electric arc furnace creates an electrical arc—essentially a continuous bolt of lightning—between large graphite electrodes. This generates a plasma with incredibly high temperatures, often exceeding 3000°C (5400°F), and is primarily used for melting steel and other alloys.

Understanding the Trade-offs and Critical Factors

Choosing a high-temperature solution involves balancing performance, cost, and operational complexity.

The Critical Role of Atmosphere

Atmosphere is the single most important factor besides temperature. Using a Molybdenum, Tungsten, or Graphite element in an oxygen-rich atmosphere will result in its immediate and catastrophic failure. The protective oxide layers on NiCr and FeCrAl alloys are what allow them to function in air.

Material Brittleness and Lifespan

Ceramic elements like SiC and MoSi₂ are strong at high temperatures but can be very brittle at room temperature and susceptible to thermal shock (cracking from rapid temperature changes). All heating elements are consumables with a finite lifespan that is heavily influenced by operating temperature and cycling frequency.

Cost vs. Performance

There is a direct correlation between temperature capability and cost. A furnace built with NiCr elements is significantly less expensive than one built with MoSi₂ elements capable of reaching higher temperatures.

Making the Right Choice for Your Application

Your selection depends entirely on your specific process requirements.

- If your primary focus is general-purpose lab or industrial heating up to 1200°C: Standard Nickel-Chromium (NiCr) or FeCrAl elements provide the best balance of cost, reliability, and ease of use.

- If your primary focus is high-temperature processing in air (1300°C - 1800°C): You must use a ceramic element, with Silicon Carbide (SiC) being a common choice and Molybdenum Disilicide (MoSi₂) for the highest ranges.

- If your primary focus is extremely high temperatures (>1800°C) or requires a non-oxidizing environment: Your choices are refractory metals (Molybdenum, Tungsten) or Graphite, both of which mandate a vacuum or inert gas furnace.

- If your primary focus is rapid, direct heating of a conductive part: Induction heating is the most efficient and precise technology for the job.

Ultimately, selecting the correct high-temperature solution requires a clear understanding of your material, your process, and your environment.

Summary Table:

| Heating Element | Max Temp in Air (°C) | Key Characteristics | Ideal For |

|---|---|---|---|

| Nickel-Chromium (NiCr) | Up to 1200°C | Ductile, protective oxide layer | General-purpose lab/industrial heating |

| Iron-Chromium-Aluminum (FeCrAl) | Up to 1425°C | Resilient aluminum oxide layer | Higher temp air applications |

| Silicon Carbide (SiC) | Up to 1625°C | Cost-effective, durable but brittle | High-temp processing in air |

| Molybdenum Disilicide (MoSi₂) | Up to 1850°C | Premium, brittle at room temperature | Highest temp air operations |

| Graphite / Refractory Metals | >2200°C | Requires vacuum/inert atmosphere | Extreme temps, non-oxidizing environments |

Need a High-Temperature Heating Solution for Your Lab?

Choosing the right heating element is critical for your process efficiency and material integrity. KINTEK specializes in lab equipment and consumables, providing expert guidance and reliable solutions for all your high-temperature heating needs.

We help you:

- Select the optimal heating element (NiCr, SiC, MoSi₂, graphite, etc.) based on your temperature and atmosphere requirements

- Ensure precise temperature control and uniform heating for consistent results

- Maximize equipment lifespan and minimize operational costs

Let's discuss your application. Our team will recommend the perfect system to achieve your goals reliably and efficiently.

Contact us today for a personalized consultation!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

People Also Ask

- What material is used for furnace heating? Select the Right Element for Your Process

- Which material is suitable for use in heating elements? Match the Right Material to Your Temperature and Atmosphere

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance