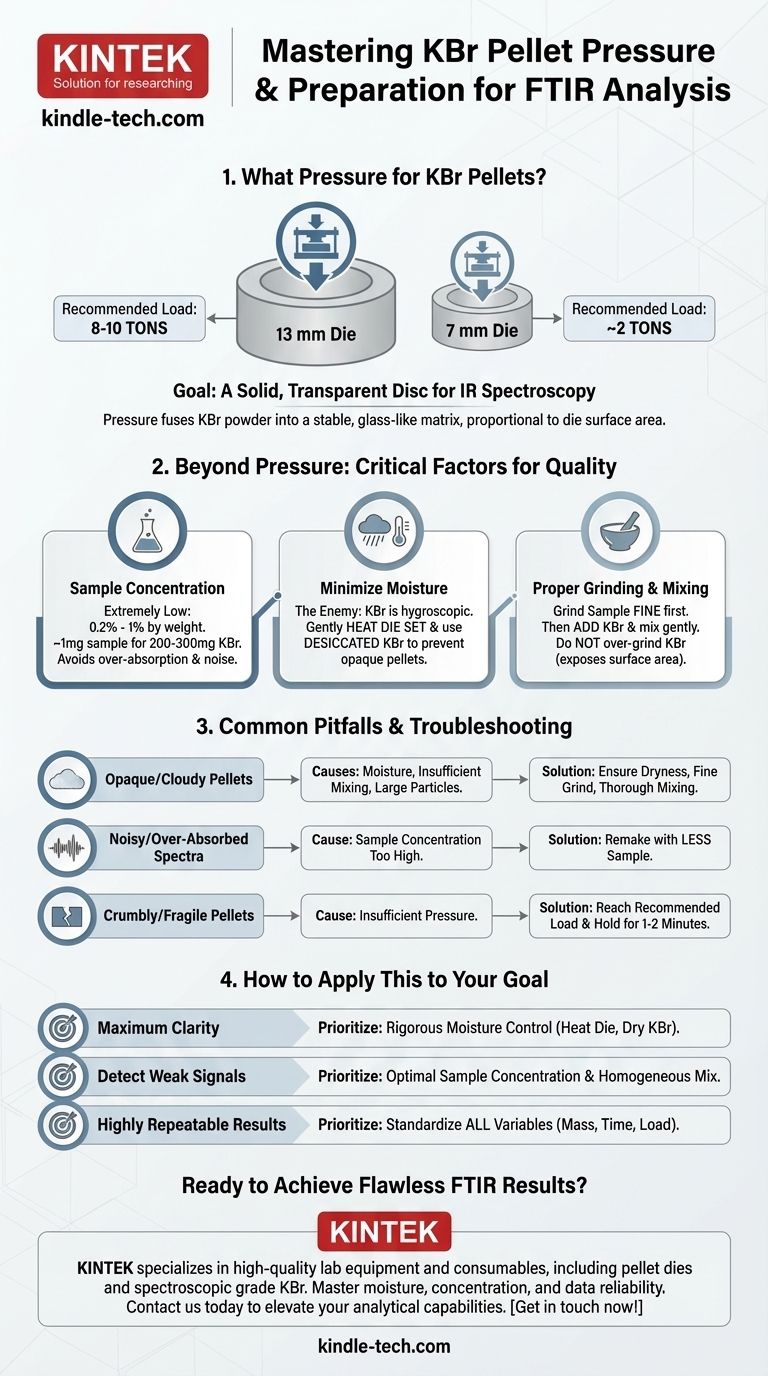

For a standard 13 mm KBr pellet die, the recommended pressing load is typically between 8 and 10 tons. This force is applied to create a solid, transparent disc suitable for infrared (IR) spectroscopy. For smaller dies, such as 7 mm, the required load is significantly lower, often around 2 tons.

While the specific pressing load is a key variable, achieving a clear, high-quality KBr pellet depends more critically on three other factors: minimizing moisture, ensuring the sample is finely ground, and achieving a low, homogeneous sample concentration.

The Role of Pressure in Pellet Formation

Pressure is what transforms the fine KBr powder into a solid, glass-like disc. Applying the correct load is essential for creating a pellet that is mechanically stable and transparent to the infrared beam.

Recommended Pressing Loads

For the most common 13 mm die, a load of 8 to 10 tons is the standard recommendation. This force is sufficient to fuse the KBr salt crystals into a solid matrix.

If you are using a smaller 7 mm die, a much lower load of approximately 2 tons is typically sufficient. The load is proportional to the surface area of the die.

The Goal: A Transparent Disc

The ultimate objective is to create a pellet that is transparent, not cloudy or opaque. A clear pellet allows the maximum amount of infrared light to pass through the sample, resulting in a clean spectrum with a stable baseline.

Beyond Pressure: Critical Factors for a Quality Pellet

Simply applying the right pressure is not enough. The quality of your FTIR spectrum is dictated by how well you prepare the material before it ever enters the press.

The Importance of Sample Concentration

Your sample concentration in the KBr should be extremely low, typically between 0.2% and 1% by weight. For a 13 mm die using 200-300 mg of KBr, this means using only around 1 mg of your sample.

Too high a concentration is the most common cause of poor results. It leads to spectra where the IR beam is completely absorbed or scattered, resulting in broad, flat-topped peaks and significant noise.

The Enemy: Moisture

Potassium bromide (KBr) is highly hygroscopic, meaning it readily absorbs moisture from the air. This is detrimental to pellet quality.

To combat this, gently heat the die set before pressing to ensure it is completely dry. Always use spectroscopic grade KBr that has been stored in a desiccator.

Proper Grinding and Mixing Technique

The key to a high-quality pellet is a homogeneous mixture. The sample must be ground into a fine powder, ideally with an agate mortar and pestle.

Critically, you should grind the sample first, then add the KBr powder and mix thoroughly without further intensive grinding. Grinding the KBr itself exposes more surface area, accelerating moisture absorption.

Common Pitfalls and How to Avoid Them

Even with the right equipment, several common issues can arise. Understanding them helps you troubleshoot your process effectively.

Opaque or Cloudy Pellets

This is almost always caused by moisture, insufficient mixing, or particles that are too large. Ensure your die is dry, your KBr is dry, and your sample is ground to a fine, consistent powder before mixing.

"Noisy" or Over-Absorbed Spectra

This problem points directly to sample concentration being too high. The IR beam cannot penetrate the sample, leading to useless data. If you see this, remake the pellet with significantly less sample.

Crumbly or Fragile Pellets

If your pellet falls apart easily, it is typically due to insufficient pressure. Ensure you are reaching the recommended load for your die size and hold the pressure for a minute or two to allow the KBr to fully compact.

How to Apply This to Your Goal

Your specific goal will determine which aspect of the process to prioritize.

- If your primary focus is maximum clarity and transparency: Concentrate on rigorous moisture control by heating your die and using perfectly dry KBr.

- If your primary focus is detecting weak spectral signals: Prioritize getting the sample concentration correct and ensuring the most homogeneous mixture possible.

- If your primary focus is creating highly repeatable results: Standardize every variable, including the total mass of KBr, the mass of the sample, mixing time, and the final pressing load.

Mastering these fundamental variables will empower you to produce high-quality KBr pellets and generate reliable spectroscopic data consistently.

Summary Table:

| Die Size | Recommended Pressing Load |

|---|---|

| 13 mm | 8 - 10 tons |

| 7 mm | ~2 tons |

Ready to achieve flawless FTIR results with perfectly pressed KBr pellets? KINTEK specializes in high-quality lab equipment and consumables, including pellet dies and spectroscopic grade KBr, designed to meet the precise needs of laboratory professionals. Our expertise ensures you can master moisture control, achieve perfect sample concentration, and generate reliable data consistently. Contact us today to find the perfect solution for your spectroscopy workflow and elevate your analytical capabilities. Get in touch now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.