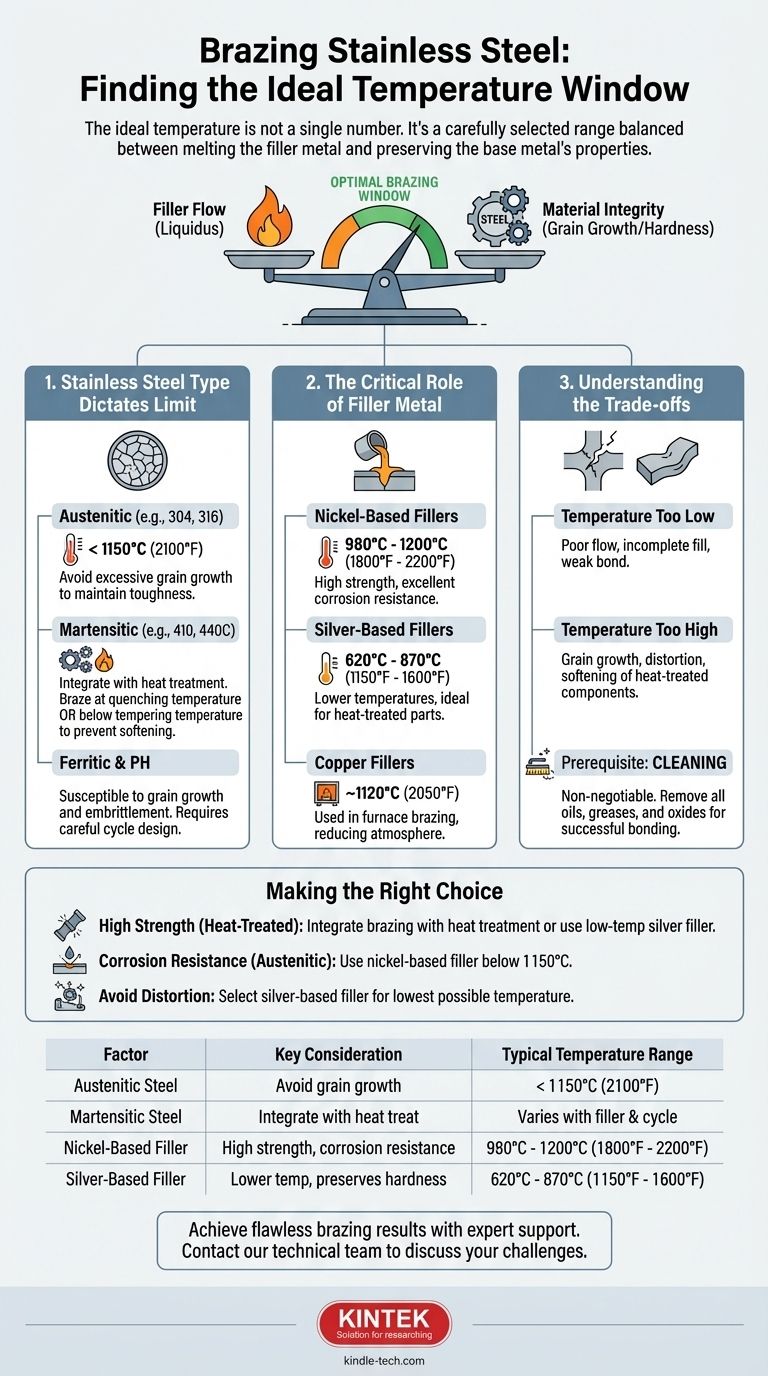

The ideal brazing temperature for stainless steel is not a single number. It is a carefully selected window determined by three critical factors: the specific type of stainless steel being joined, the composition of the brazing filler metal, and the desired final properties of the assembly. Choosing the right temperature is a balancing act to ensure a strong joint without compromising the integrity of the base metal.

The core challenge of brazing stainless steel is to find a temperature high enough to melt the filler metal for proper flow, but low enough to avoid damaging the steel's metallurgical structure and mechanical properties. This temperature is a function of the material, not a fixed constant.

Why Stainless Steel Type Dictates Temperature

Different families of stainless steel react to heat in vastly different ways. Applying the wrong thermal cycle can permanently weaken the material, even if the brazed joint itself appears sound.

Brazing Austenitic Stainless Steels (e.g., 304, 316)

Austenitic steels are the most common and are generally forgiving. However, they have a critical upper temperature limit.

The primary constraint is preventing excessive grain growth, which can reduce the steel's toughness and ductility. For this reason, the brazing temperature should not exceed 1150°C (2100°F).

Brazing Martensitic Stainless Steels (e.g., 410, 440C)

These are hardenable steels, and their properties are highly dependent on heat treatment. Brazing must be integrated with this heat treatment to be successful.

You have two primary strategies:

- Braze at the Quenching Temperature: Combine the brazing and hardening steps by using a filler metal that flows at the steel's austenitizing (quenching) temperature.

- Braze Below the Tempering Temperature: If the part is already hardened and tempered, you must use a low-temperature filler metal. The brazing temperature must remain below the final tempering temperature to prevent softening and loss of hardness.

Brazing Ferritic and PH Steels

Ferritic steels (e.g., 430) are also susceptible to grain growth at high temperatures, which can cause significant embrittlement.

Precipitation-Hardening (PH) steels (e.g., 17-4 PH) behave similarly to martensitic grades. The brazing thermal cycle must be carefully designed to be compatible with the steel's specific aging and solution treatment cycles to achieve the required strength.

The Critical Role of Filler Metal

The filler metal is the other half of the temperature equation. The brazing process must take place above the filler's liquidus temperature (the point at which it is fully molten) to ensure it can flow into the joint via capillary action.

Common Filler Metal Families

- Nickel-Based Fillers: These are very common for stainless steel due to their high strength and excellent corrosion resistance. They typically require high brazing temperatures, often in the 980°C to 1200°C (1800°F to 2200°F) range.

- Silver-Based Fillers: Also known as silver solder, these alloys allow for much lower brazing temperatures, typically 620°C to 870°C (1150°F to 1600°F). They are ideal for heat-treated parts where preserving hardness is critical.

- Copper Fillers: Pure copper is often used in furnace brazing under a reducing atmosphere. It requires a high temperature, typically around 1120°C (2050°F).

Understanding the Trade-offs

Choosing a temperature is about managing risks. Deviating from the optimal window in either direction will lead to failure.

Consequence of Temperature Too Low

If the temperature is not high enough for the selected filler metal, you will get poor results. The filler will not melt and flow properly, leading to incomplete joint fill, poor "wetting" of the base metal, and a weak, unreliable bond.

Consequence of Temperature Too High

Exceeding the correct temperature is often more dangerous. It can cause irreversible damage to the stainless steel, including excessive grain growth, distortion of the part, or the softening of heat-treated components.

The Non-Negotiable Prerequisite: Cleaning

No temperature or filler metal can compensate for a contaminated surface. Stainless steel forms a passive, transparent oxide layer that must be removed. All oils, greases, and oxides must be meticulously cleaned from the joint surfaces immediately before brazing to allow the filler metal to bond with the base metal.

Making the Right Choice for Your Goal

Select your brazing temperature by first defining your material and your primary objective for the finished part.

- If your primary focus is high strength in a heat-treated part: You must integrate the brazing cycle with the heat treatment, either by brazing at the quenching temperature or by using a low-temperature silver filler below the tempering temperature.

- If your primary focus is corrosion resistance and general use (Austenitic Steel): Choose a nickel-based filler and braze in a window that is well below the 1150°C (2100°F) grain growth limit.

- If your primary focus is avoiding distortion or thermal damage to a sensitive assembly: Select a silver-based filler to perform the braze at the lowest possible temperature.

By understanding these governing principles, you can engineer a reliable brazing process tailored specifically to your materials and application.

Summary Table:

| Factor | Key Consideration | Typical Temperature Range |

|---|---|---|

| Austenitic Steel (304, 316) | Avoid grain growth | < 1150°C (2100°F) |

| Martensitic Steel (410, 440C) | Integrate with heat treatment | Varies with filler metal & heat treat cycle |

| Nickel-Based Filler | High strength, corrosion resistance | 980°C - 1200°C (1800°F - 2200°F) |

| Silver-Based Filler | Lower temp, preserves hardness | 620°C - 870°C (1150°F - 1600°F) |

Achieve flawless stainless steel brazing results with expert support.

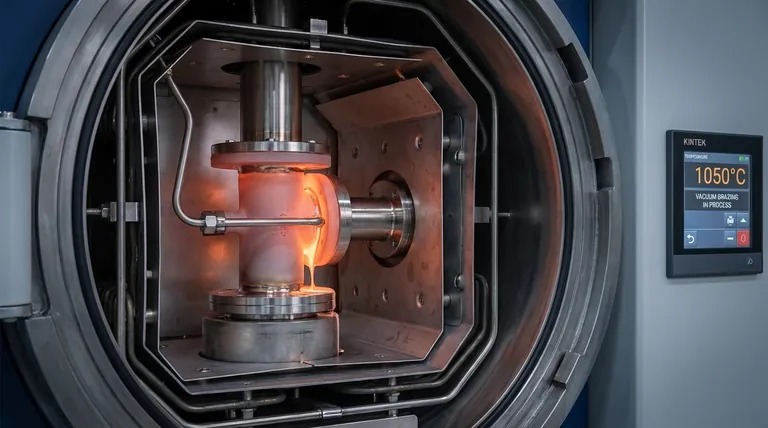

Brazing stainless steel requires precise control over temperature and atmosphere to prevent damage and ensure joint integrity. KINTEK specializes in the lab equipment and consumables needed for successful brazing processes, from high-temperature furnaces to surface preparation materials.

Let our expertise help you select the right equipment and parameters for your specific stainless steel type and application. Contact our technical team today to discuss your brazing challenges and ensure strong, reliable joints.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is oxidation in brazing? How to prevent it for strong, durable joints