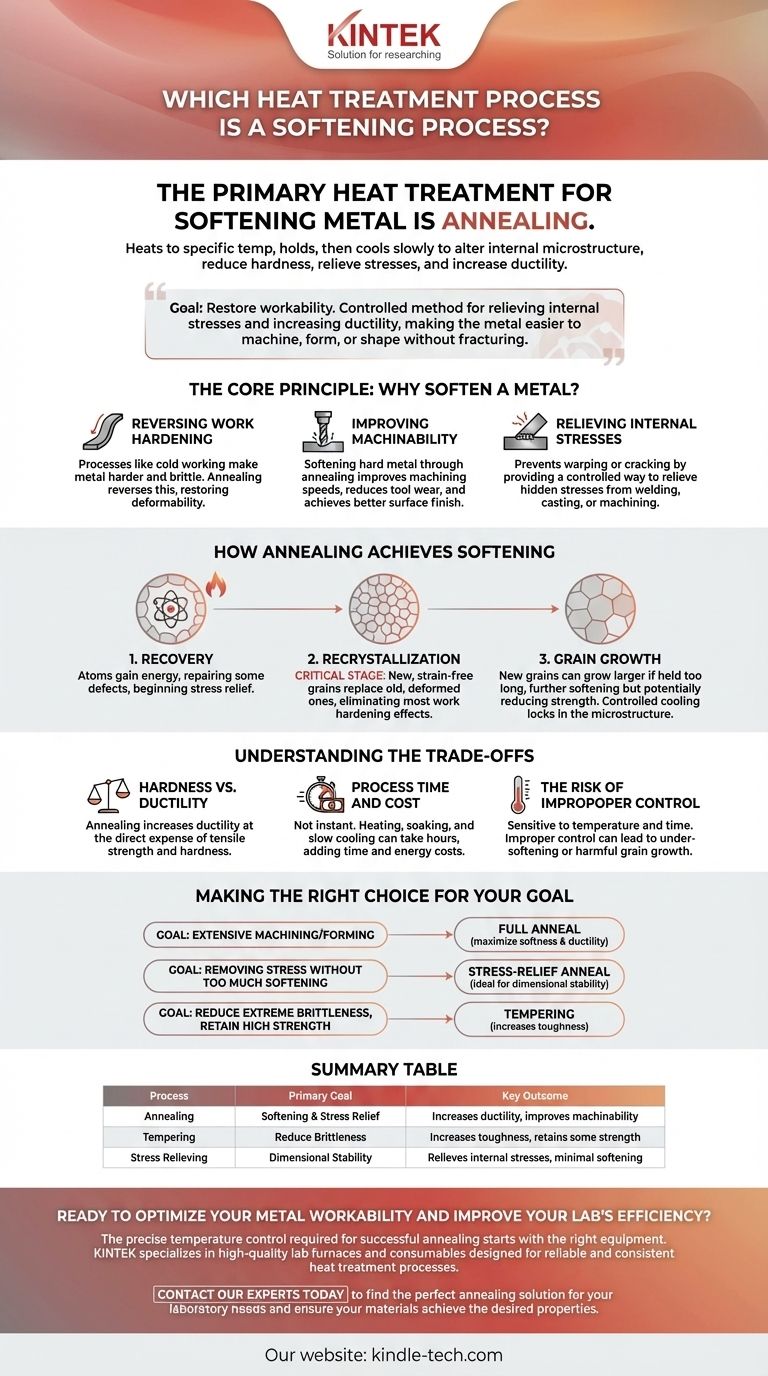

The primary heat treatment for softening metal is annealing. This process involves heating a metal to a specific temperature, holding it there for a period, and then cooling it slowly. By carefully controlling this cycle, annealing alters the metal's internal microstructure to reduce hardness, relieve internal stresses, and increase its ductility.

The goal of a softening process like annealing isn't simply to make a material less hard; it's to restore its workability. It's a controlled method for relieving internal stresses and increasing ductility, making the metal easier to machine, form, or shape without fracturing.

The Core Principle: Why Soften a Metal?

Hardness is often a desirable trait, but many manufacturing processes require a material to be in a softer, more malleable state. Softening processes are a critical intermediate step.

Reversing the Effects of Work Hardening

Processes like rolling, drawing, or bending a metal at room temperature (known as cold working) make it harder and stronger, but also significantly more brittle. Annealing reverses this effect, restoring the metal's ability to be deformed further.

Improving Machinability

A very hard metal is difficult and slow to cut, drill, or mill. By softening the material through annealing, you can dramatically improve machining speeds, reduce tool wear, and achieve a better surface finish.

Relieving Internal Stresses

Welding, casting, and heavy machining can create significant internal stresses within a material. These hidden stresses can cause the part to warp over time or crack unexpectedly. Annealing provides a controlled way to relieve these stresses, ensuring dimensional stability and reliability.

How Annealing Achieves Softening

The "magic" of annealing happens at the microscopic level by changing the metal's grain structure. The process can be broken down into three fundamental stages.

Stage 1: Recovery

As the metal is heated, its atoms gain energy. This initial phase allows the internal atomic structure to repair some of the defects caused by cold working, which begins to relieve internal stresses.

Stage 2: Recrystallization

This is the most critical stage for softening. As the temperature rises to a specific point, new, strain-free microscopic grains begin to form and grow, replacing the old, deformed, and stressed grains. This fundamental change in the microstructure is what eliminates most of the effects of work hardening.

Stage 3: Grain Growth

If the metal is held at the annealing temperature for too long, the new, stress-free grains will continue to grow larger. This can further soften the material, but excessive grain growth can sometimes decrease its strength. The cooling rate is then carefully controlled to lock in this new, softer microstructure.

Understanding the Trade-offs

No heat treatment exists in a vacuum. Choosing to soften a material involves accepting a clear set of compromises.

Hardness vs. Ductility

This is the central trade-off. Annealing increases ductility (the ability to deform without breaking) at the direct expense of tensile strength and hardness. You are exchanging strength for workability.

Process Time and Cost

Annealing is not an instant process. The heating, soaking, and especially the slow cooling phases can take many hours. This adds time and energy costs to the manufacturing workflow.

The Risk of Improper Control

The annealing process is highly sensitive to temperature and time. If the temperature is too low, the metal won't fully soften. If it's too high or held for too long, the grains can grow too large, potentially harming the final mechanical properties of the component.

Making the Right Choice for Your Goal

Selecting the right heat treatment depends entirely on what you need to achieve with the material.

- If your primary focus is preparing a material for extensive machining or forming: A full anneal is the correct choice to maximize softness and ductility.

- If your primary focus is removing stress from a finished part without making it too soft: A lower-temperature stress-relief anneal is the ideal solution.

- If your primary focus is to reduce the extreme brittleness of a hardened part while retaining high strength: You would use a related but distinct process called tempering, which slightly softens the material to gain significant toughness.

Ultimately, understanding annealing empowers you to control a material's properties, turning a hard, brittle metal into a workable and reliable component.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Annealing | Softening & Stress Relief | Increases ductility, improves machinability |

| Tempering | Reduce Brittleness | Increases toughness, retains some strength |

| Stress Relieving | Dimensional Stability | Relieves internal stresses, minimal softening |

Ready to optimize your metal workability and improve your lab's efficiency?

The precise temperature control required for successful annealing starts with the right equipment. KINTEK specializes in high-quality lab furnaces and consumables designed for reliable and consistent heat treatment processes.

Contact our experts today to find the perfect annealing solution for your laboratory needs and ensure your materials achieve the desired properties.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is a furnace used for sintering? Creating High-Performance Solid Components from Powder

- How does vacuum arc melting work? Unlock High-Purity Metals for Critical Applications

- What are the applications of brazing? Join Dissimilar Metals & Create Leak-Proof Seals

- Which heat treatment is best? Choose the Right Process for Your Metal's Properties

- What is classification of heating furnace? A Guide to Selecting the Right Industrial Furnace

- What are the two basic classes of furnaces used in heat treatment? Choose the Right Environment for Your Metal

- Why is a vacuum oven necessary for CSD tungsten coatings? Ensure Precise Evaporation and Coating Integrity

- Is brazing done in a vacuum furnace? Achieve Superior Joint Strength and Purity