Measuring moisture and ash content is fundamental to ensuring food safety, quality, and regulatory compliance. These two seemingly simple metrics act as powerful indicators for a food product's stability, nutritional value, and purity. They are not just numbers on a spec sheet; they are critical data points that influence decisions from processing and packaging to pricing and labeling.

While not primary nutrients themselves, moisture and ash content are critical proxies for food stability and total mineral composition. Mastering their analysis is essential for controlling product quality, meeting legal requirements, and ensuring economic viability.

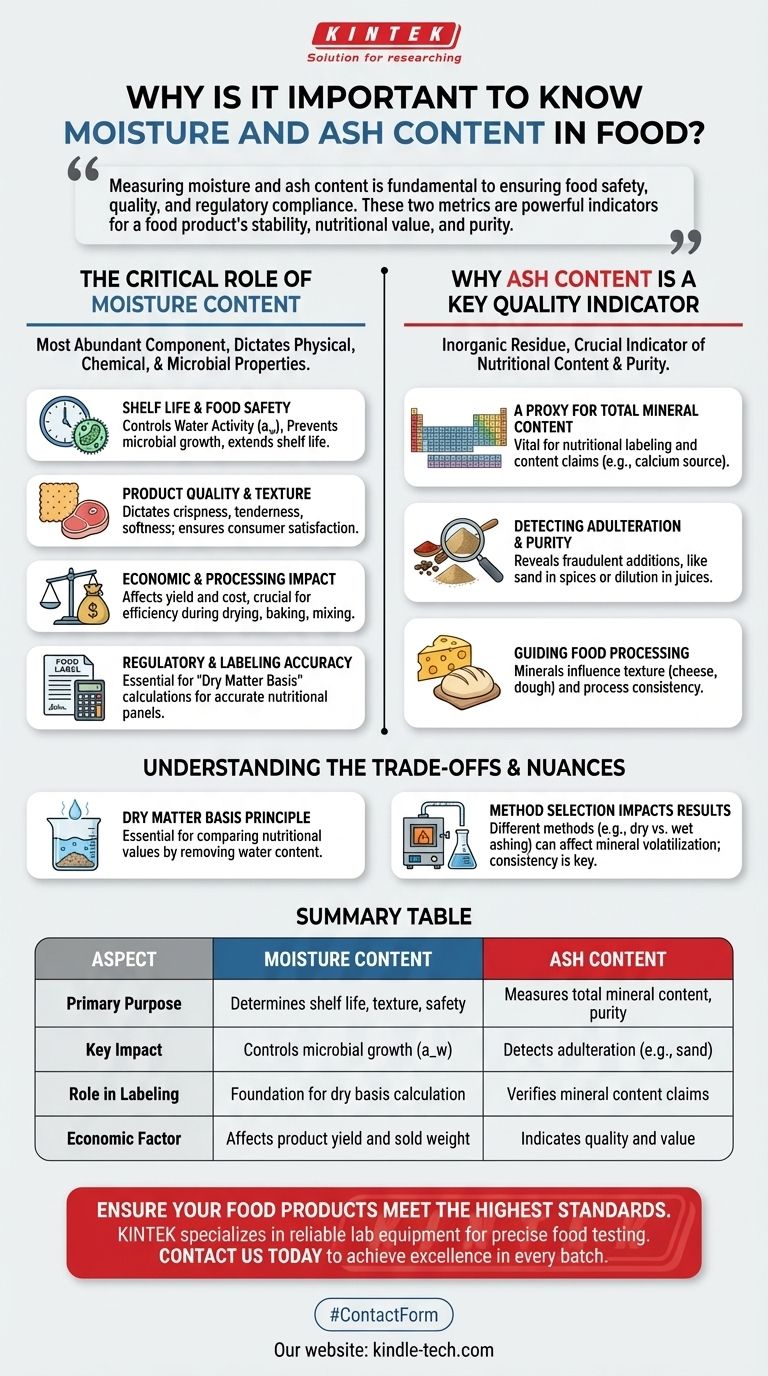

The Critical Role of Moisture Content

Moisture is the most abundant component in many foods, and its precise measurement is non-negotiable for several reasons. It directly dictates the physical, chemical, and microbial properties of a product.

Shelf Life and Food Safety

The amount of free water in a food, known as water activity (a_w), is the single most important factor in determining its susceptibility to spoilage.

High moisture levels promote the growth of bacteria, yeasts, and molds, drastically reducing shelf life and posing significant food safety risks. Controlling moisture is a primary strategy for food preservation.

Product Quality and Texture

Moisture content is directly responsible for the textural attributes consumers expect. It dictates the crispness of a cracker, the tenderness of meat, and the softness of baked goods.

Even minor deviations from the target moisture percentage can lead to a product that is stale, soggy, or unpalatable, resulting in consumer complaints and brand damage.

Economic and Processing Impact

Water is an inexpensive ingredient, and its content directly affects product yield and cost. In many industries, products are sold by weight, making precise moisture control an economic imperative.

Furthermore, moisture levels must be monitored during processing steps like drying, baking, and mixing to ensure efficiency and consistency. For example, knowing the initial moisture content is crucial for calculating the required drying time.

Regulatory and Labeling Accuracy

Nutritional information on food labels is often calculated on a "dry matter basis." This requires first measuring the moisture content and then mathematically removing it to accurately report the percentage of protein, fat, and carbohydrates.

An incorrect moisture reading will skew every other value on the nutritional panel, leading to non-compliance with regulations from agencies like the FDA.

Why Ash Content is a Key Quality Indicator

Ash is the inorganic residue that remains after all the organic matter (fat, protein, carbohydrates) has been burned away. While it sounds like a measure of waste, it is actually a crucial indicator of nutritional content and purity.

A Proxy for Total Mineral Content

The ash content represents the total amount of minerals within a food product. This is a vital measurement for nutritional labeling and making content claims like "good source of calcium" or "rich in minerals."

While ash analysis doesn't identify individual minerals, it provides a quick and essential measure of the food's overall mineral profile.

Detecting Adulteration and Purity

Ash analysis is a powerful tool for quality control and the detection of fraudulent additions. For instance, an unusually high ash content in ground spices could indicate the presence of sand or soil.

Similarly, in fruit juices, a specific ash profile is expected. Deviations can suggest that the juice has been diluted or adulterated with cheaper ingredients.

Guiding Food Processing

The mineral components within the ash can significantly affect the physicochemical properties of food during processing.

For example, minerals like calcium and magnesium can influence the texture of cheese, the stability of emulsions, and the dough-handling properties in bakeries. Monitoring ash helps maintain process consistency.

Understanding the Trade-offs and Nuances

While moisture and ash are foundational metrics, interpreting them requires an understanding of their context and the methods used to measure them.

The "Dry Matter Basis" Principle

Moisture and other nutrients have an inverse relationship. A food with 90% moisture only has 10% of its weight available for protein, fat, carbs, and minerals.

This is why comparing the nutritional value of two different foods (e.g., fresh milk vs. milk powder) must be done on a dry matter basis to be meaningful.

Method Selection Impacts Results

As the references note, different methods exist for measuring ash (e.g., dry ashing, wet ashing). The chosen method can impact the final value, as high temperatures can cause certain minerals to volatilize and be lost.

For this reason, it is critical to use standardized, consistent methods for quality control to ensure your results are comparable over time and across different batches.

A Common Pitfall: Confusing Ash with Specific Minerals

Remember that "total ash" is a cumulative measure. It tells you the total mineral content but does not differentiate between essential minerals like iron and potassium or less desirable elements.

If you need to quantify a specific mineral for a nutritional claim, further analysis using techniques like Atomic Absorption (AA) or Inductively Coupled Plasma (ICP) is required after the initial ashing process.

Making the Right Choice for Your Goal

Moisture and ash are not just academic exercises; they are practical tools for managing food production. How you use this data depends on your primary objective.

- If your primary focus is quality control: Use moisture and ash as rapid, reliable indicators of product consistency and potential contamination.

- If your primary focus is product development: Manipulate moisture content to achieve desired textures and shelf stability, while monitoring ash to ensure nutritional targets are met.

- If your primary focus is regulatory compliance: Ensure your moisture analysis is accurate, as it is the foundation for calculating all other nutrient values for labeling.

Ultimately, mastering the analysis of moisture and ash gives you fundamental control over the safety, quality, and legality of your food product.

Summary Table:

| Aspect | Moisture Content | Ash Content |

|---|---|---|

| Primary Purpose | Determines shelf life, texture, and safety | Measures total mineral content and purity |

| Key Impact | Controls microbial growth (water activity) | Detects adulteration (e.g., sand in spices) |

| Role in Labeling | Foundation for calculating nutrients on a dry basis | Verifies mineral content for nutritional claims |

| Economic Factor | Affects product yield and sold weight | Indicates quality and value |

Ensure your food products meet the highest standards of safety and quality. Accurate moisture and ash analysis is fundamental to your success. KINTEK specializes in providing reliable lab equipment and consumables for precise food testing.

Our solutions help you control product consistency, ensure regulatory compliance, and protect your brand reputation. Contact us today to find the perfect analytical tools for your laboratory needs and let us help you achieve excellence in every batch.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Three-dimensional electromagnetic sieving instrument

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the use of muffle furnace in chemistry? Achieve Contaminant-Free Heating for Accurate Analysis

- What is the temperature of a muffle furnace? It's Not a Single Number—Find Your Perfect Range

- What are the types of ashing? Explore Methods for Accurate Sample Analysis

- How does a laboratory muffle furnace contribute to the generation of active metal oxide components? Optimize Catalysis

- What critical process conditions does a high-temperature box resistance furnace provide? Expert Catalyst Calcination

- How do high-temperature laboratory furnaces assist in enhancing C/C composites? Achieve 7.5x Better Corrosion Resistance

- What is the function of a muffle furnace in forming Ag/Ce-Mn solid solutions? Optimize Your Catalyst Synthesis

- What are the hazards of laboratory oven? Avoid Burns, Toxic Fumes, and Fire Risks