In short, no. A properly applied Physical Vapor Deposition (PVD) coating does not fade in the way that paint or dyes do. Its color is created by a highly durable, bonded layer of material, making it exceptionally resistant to the sun's UV rays and discoloration over time. The "fading" people sometimes perceive is actually the result of the coating slowly wearing away due to extreme abrasion.

The core issue isn't about color stability but about mechanical endurance. PVD coatings are incredibly hard and do not fade, but they are not indestructible. Their longevity is ultimately determined by how well they resist being physically worn off over years of use.

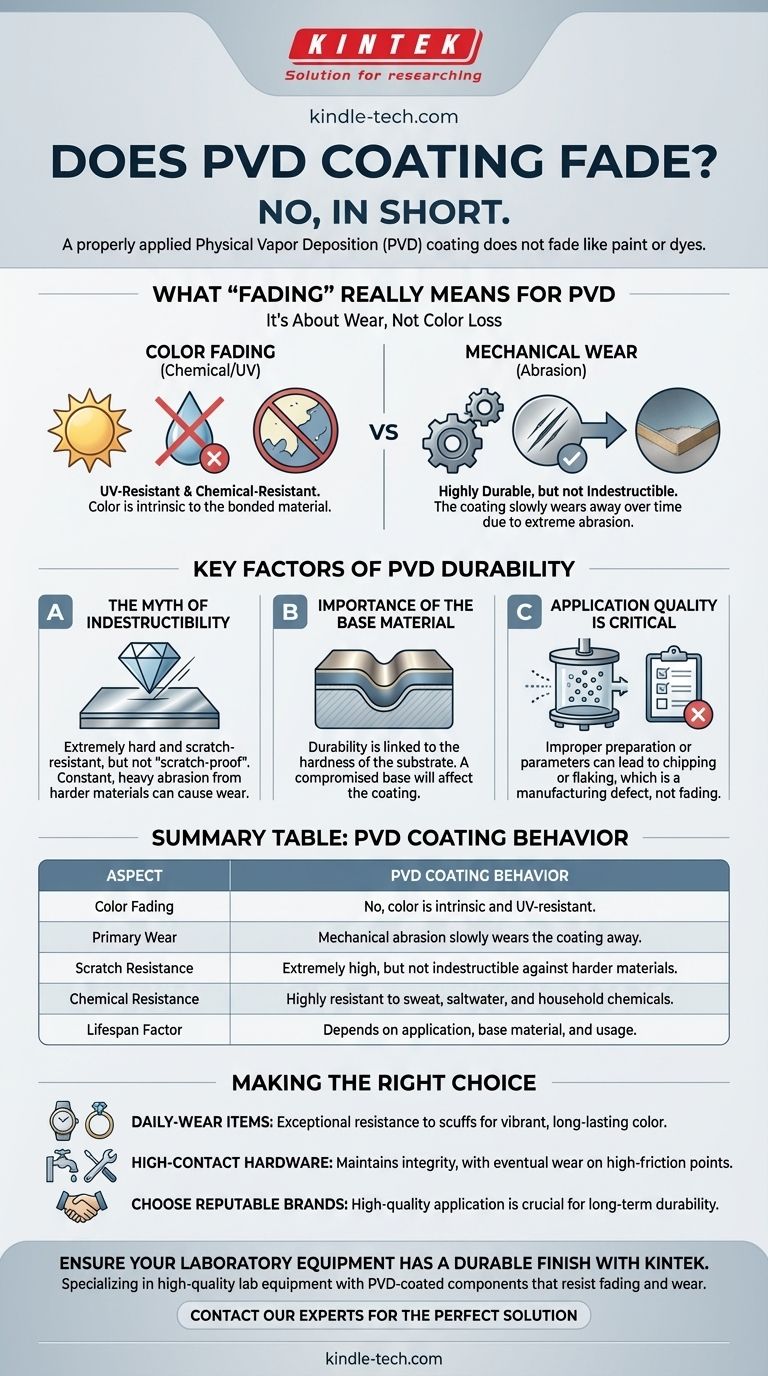

What "Fading" Really Means for PVD

To understand PVD's durability, it's crucial to distinguish between chemical fading (color loss) and mechanical wear (material loss). PVD excels at resisting the former but is merely highly resistant to the latter.

It's About Wear, Not Color Loss

A PVD coating isn't a layer of paint. It's a thin film of metal or ceramic that is atomically bonded to the surface of the base material in a vacuum chamber.

The color you see is the intrinsic property of that bonded material. Therefore, it cannot "fade" or lose its color. For the color to disappear, the coating itself must be physically worn away, exposing the substrate material underneath.

The Myth of Indestructibility

PVD coatings are often described as being nearly as hard as diamond. This makes them incredibly difficult to scratch and gives them their superior wear resistance compared to traditional finishes like electroplating.

However, "scratch-resistant" does not mean "scratch-proof." Constant, heavy abrasion from harder materials (like sand, diamonds, or other hardened surfaces) can eventually wear down even the toughest PVD finish.

The Importance of the Base Material

The durability of the coating is also linked to the hardness of the material it is applied to.

If a soft base metal like aluminum gets a deep scratch or dent, the PVD coating on top will be compromised along with it. The coating is only as durable as the foundation it rests upon.

Understanding the Trade-offs and Failure Points

While PVD is the most durable coating widely available, its performance depends on several factors. Knowing these helps set realistic expectations for its lifespan.

Application Quality is Critical

The PVD process is highly technical. Improper surface preparation or incorrect parameters during the coating process can lead to poor adhesion.

In these rare cases, the coating will not "fade" but may chip or flake off. This is a sign of a manufacturing defect, not a limitation of PVD technology itself.

Scratches vs. Fading

A deep gouge from a significant impact can penetrate the PVD layer and expose the silver-colored metal underneath.

This is mechanical damage, not fading. The surrounding PVD coating will remain its original color, perfectly stable and unchanged.

Harsh Chemical Resistance

PVD coatings are highly non-reactive and resistant to corrosion from sweat, saltwater, and most household chemicals. This is why they are a superior choice for watches, jewelry, and fixtures.

Only prolonged exposure to highly corrosive industrial acids or chemicals could potentially damage the coating, which is not a concern for virtually any consumer application.

Making the Right Choice for Your Goal

PVD is an investment in longevity. Understanding how it performs in different scenarios ensures you get the value you expect.

- If your primary focus is daily-wear items (watches, jewelry): PVD offers exceptional resistance to the scuffs and scratches of normal life, ensuring the color remains vibrant for many years, far outlasting traditional plating.

- If your primary focus is high-contact hardware (faucets, tools): The coating will maintain its color and integrity extremely well, though you can expect eventual wear on sharp edges or high-friction points after years of heavy use.

- If you are considering a PVD-coated product: Prioritize reputable brands known for high-quality application, as the process is as important as the material for long-term durability.

Ultimately, choosing a PVD-coated product is a decision for superior, long-lasting color and finish that resists fading through exceptional hardness.

Summary Table:

| Aspect | PVD Coating Behavior |

|---|---|

| Color Fading | No, color is intrinsic to the bonded material and is UV-resistant. |

| Primary Wear | Mechanical abrasion slowly wears the coating away over time. |

| Scratch Resistance | Extremely high, but not indestructible against harder materials. |

| Chemical Resistance | Highly resistant to sweat, saltwater, and household chemicals. |

| Lifespan Factor | Depends on application quality, base material hardness, and usage. |

Ensure your laboratory equipment has a durable, long-lasting finish. KINTEK specializes in high-quality lab equipment and consumables, offering PVD-coated components that resist fading and wear, ensuring your instruments look professional and perform reliably for years. Contact our experts today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- Is diamond coating worth it? Maximize Component Life and Performance