The primary advantages of a channel induction furnace are its exceptional energy efficiency for holding large volumes of molten metal, its precise and consistent temperature control, and its clean melting process. Because it functions like a transformer to heat a specific "channel" of metal, it is an ideal choice for applications requiring a large, stable reservoir of liquid metal, such as feeding a die-casting line or superheating iron from a primary melter.

The core principle to understand is that a channel induction furnace excels as a highly efficient holding vessel, not just a melter. Its design makes it uniquely suited for maintaining large quantities of molten metal at an exact temperature for extended periods with minimal energy consumption.

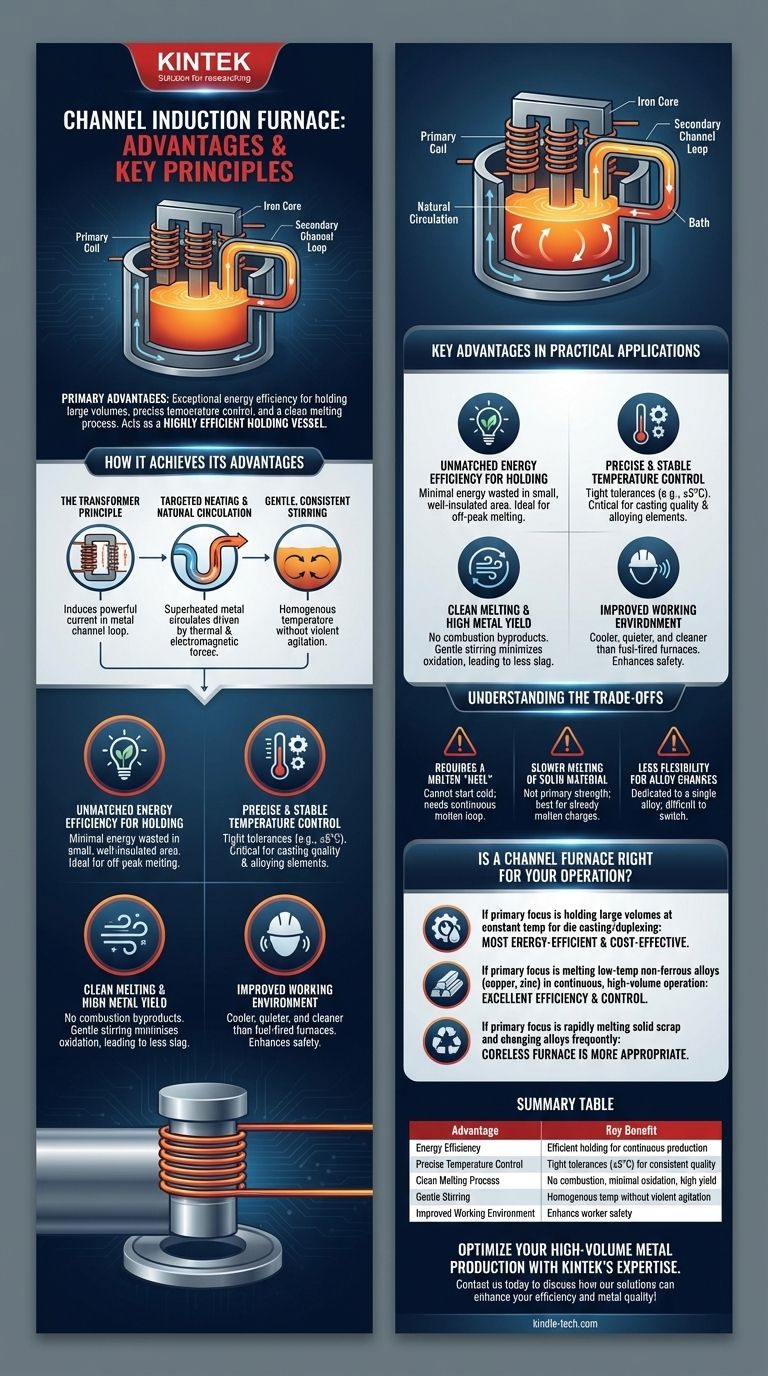

How a Channel Furnace Achieves Its Advantages

A channel furnace’s unique benefits stem directly from its specialized design, which operates fundamentally differently from other induction furnaces.

The Transformer Principle

A channel furnace is essentially a transformer where the secondary coil is a closed loop of the molten metal itself. A primary induction coil is wrapped around an iron core, which is connected to the main furnace bath via a narrow "channel" or "throat." When power is applied, it induces a powerful current in the metal loop, generating intense heat precisely where it's needed.

Targeted Heating and Natural Circulation

The heat is generated exclusively within this confined metal loop. This superheated metal becomes less dense and, driven by both thermal and electromagnetic forces, circulates out into the main furnace bath. Cooler metal from the bath is then drawn into the channel to be heated, creating a continuous and natural circulation pattern.

Gentle, Consistent Stirring

This circulation provides a constant, gentle stirring action throughout the entire molten bath. This is crucial for maintaining a homogenous temperature and chemical composition without the violent agitation that can introduce gasses or damage refractories.

Key Advantages in Practical Applications

This unique design translates into significant operational benefits, particularly in high-volume, continuous production environments.

Unmatched Energy Efficiency for Holding

Because heat is generated in a small, well-insulated area, very little energy is wasted. This makes the channel furnace incredibly efficient for holding metal at temperature, often consuming significantly less power than a coreless furnace for the same task. This allows facilities to melt metal during off-peak hours at a lower cost and hold it for use during peak hours.

Precise and Stable Temperature Control

The electrical nature of the heating allows for immediate and precise power adjustments. This enables the furnace to hold the molten bath within very tight temperature tolerances (e.g., ±5°C), which is critical for casting quality and preventing the loss of valuable, temperature-sensitive alloying elements.

Clean Melting and High Metal Yield

Like all induction furnaces, there is no combustion involved. This means no byproducts of fuel can contaminate the melt. The gentle stirring and contained nature of the process also minimize oxidation, leading to less slag (dross) and a higher yield of usable metal from the raw material.

Improved Working Environment

The absence of combustion results in a significantly cooler, quieter, and cleaner working environment compared to traditional fuel-fired furnaces. This improves worker safety and comfort and reduces the need for extensive ventilation and pollution control systems.

Understanding the Trade-offs

No technology is perfect for every situation. The specialized design of a channel furnace comes with specific limitations that are critical to understand.

The Requirement for a Molten "Heel"

A channel furnace cannot be started from a cold, solid state. It requires a continuous loop of molten metal—a "heel"—to be present at all times to complete the electrical circuit. This makes it unsuitable for operations that shut down completely on a daily basis.

Slower Melting of Solid Material

While it can melt solid charges, it is not its primary strength. Its melting rate is generally slower than a coreless furnace of a similar power rating. It is most effective when charged with already molten metal.

Less Flexibility for Alloy Changes

The need to maintain a heel makes it difficult to switch between different types of alloys. Draining the furnace completely is a significant undertaking, so channel furnaces are typically dedicated to a single alloy for long campaigns.

Is a Channel Furnace Right for Your Operation?

Choosing the right furnace depends entirely on your production needs.

- If your primary focus is holding large volumes of metal at a constant temperature for die casting or duplexing: A channel furnace is the most energy-efficient and cost-effective technology available.

- If your primary focus is melting low-temperature, non-ferrous alloys like copper or zinc in a continuous, high-volume operation: The channel furnace provides excellent efficiency and control for this specific application.

- If your primary focus is rapidly melting various types of solid scrap and frequently changing alloys: A coreless induction furnace offers the necessary flexibility and is the more appropriate choice.

Ultimately, understanding that the channel furnace is a specialized holding and superheating tool is the key to leveraging its significant advantages.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Highly efficient for holding large volumes of molten metal, ideal for continuous production. |

| Precise Temperature Control | Maintains tight temperature tolerances (±5°C) for consistent casting quality. |

| Clean Melting Process | No combustion byproducts, minimal oxidation, and higher metal yield. |

| Gentle Stirring | Natural circulation ensures homogenous temperature without violent agitation. |

| Improved Working Environment | Cooler, quieter, and cleaner than fuel-fired furnaces, enhancing worker safety. |

Optimize your high-volume metal production with KINTEK's expertise in lab and industrial furnace solutions. If your operation requires a stable, energy-efficient reservoir of molten metal for die-casting, duplexing, or superheating applications, a channel induction furnace could be your ideal solution. KINTEK specializes in providing reliable lab equipment and consumables tailored to laboratory and industrial needs. Contact us today to discuss how our solutions can enhance your efficiency and metal quality!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys