The primary advantages of a core induction furnace are its exceptional energy efficiency and suitability for high-throughput, continuous melting operations. This design operates like a transformer where the molten metal forms a secondary circuit, allowing for extremely efficient heating with minimal energy loss. This makes it a preferred choice in large-scale foundries dedicated to a limited range of alloys.

A core induction furnace excels in high-volume, continuous melting environments where a single alloy is processed for long periods, offering unparalleled energy efficiency. However, this specialization comes with significant trade-offs in operational flexibility and maintenance.

How a Core Furnace Achieves Its Advantages

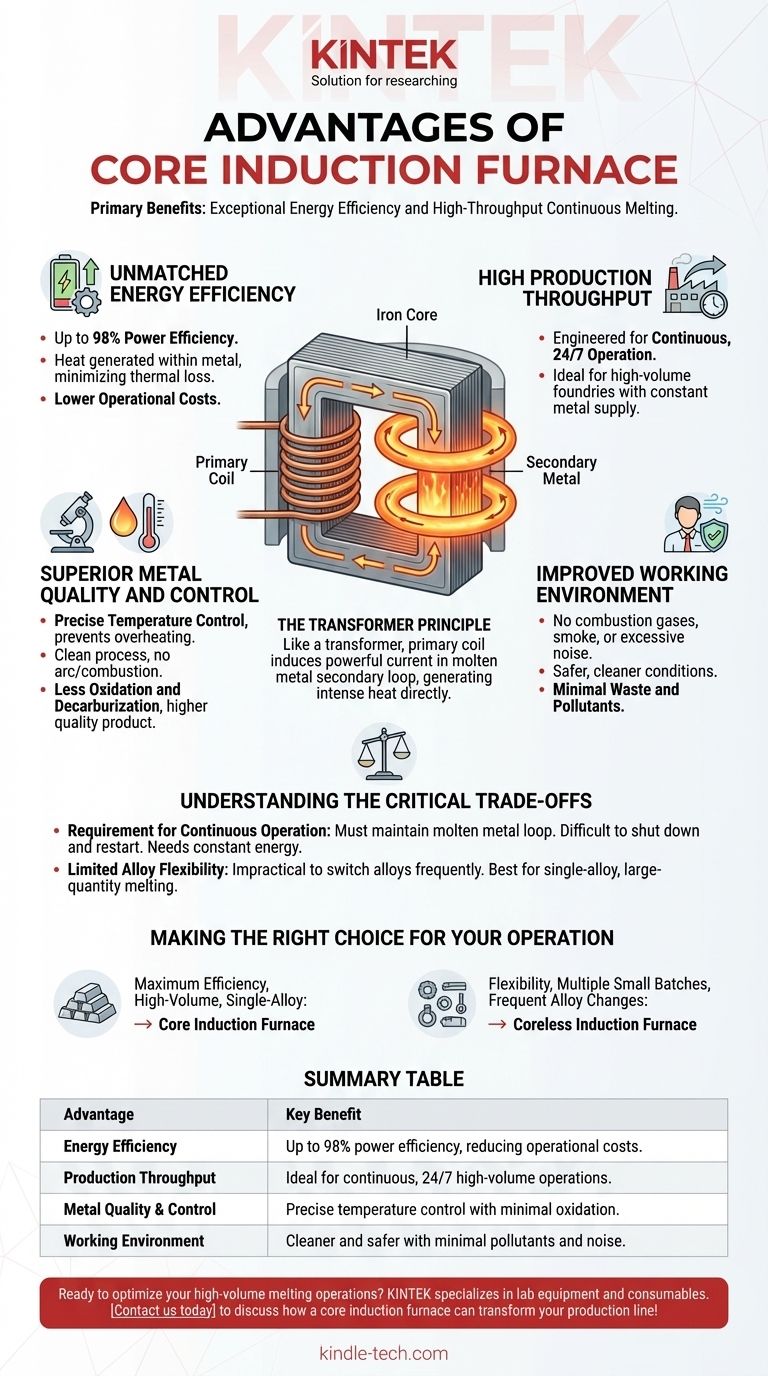

The Transformer Principle

A core-type furnace functions on a basic transformer principle. A primary coil is wound around a laminated iron core, and a loop of molten metal acts as the secondary coil.

When an alternating current passes through the primary coil, it induces a powerful current in the molten metal loop, generating intense heat directly within the charge.

This direct heating method is the source of its primary benefits.

Key Advantages Explained

Unmatched Energy Efficiency

The furnace's design as a tightly coupled transformer is remarkably effective. It can achieve a power efficiency of up to 98%, minimizing wasted energy.

Because heat is generated within the metal itself, there is very little thermal loss to the surrounding environment compared to combustion-based methods. This translates directly to lower operational costs.

High Production Throughput

Core furnaces are engineered for continuous, 24/7 operation.

Their high efficiency and capacity make them ideal for high-production foundries that require a constant, predictable supply of molten metal with few interruptions.

Superior Metal Quality and Control

Induction heating allows for precise temperature control, preventing the overheating and loss of valuable alloying elements.

Since there is no arc or combustion, the process is incredibly clean. This leads to less oxidation and decarburization, preserving the integrity of the metal and resulting in a higher quality final product.

Improved Working Environment

The absence of combustion gases, smoke, and excessive noise creates a much safer and cleaner working environment for operators.

This contributes to improved working conditions and helps facilities meet stringent environmental and pollution regulations. The process itself generates minimal waste and pollutants.

Understanding the Critical Trade-offs

Requirement for Continuous Operation

The most significant limitation is the need to maintain a continuous molten metal loop. A core furnace cannot be easily shut down and restarted.

It must be kept running and hot even when not actively melting, which requires a constant energy input. This makes it unsuitable for operations that do not run continuously.

Limited Alloy Flexibility

The continuous molten heel makes it impractical to switch between different alloys frequently. Doing so would require emptying the furnace, which is a difficult and time-consuming process.

Consequently, these furnaces are best suited for operations dedicated to melting large quantities of a single alloy with few changes.

Making the Right Choice for Your Operation

Choosing the right furnace technology depends entirely on your production model.

- If your primary focus is maximum efficiency in a high-volume, single-alloy foundry: The core induction furnace is likely the optimal choice due to its low energy consumption per ton and high throughput.

- If your primary focus is flexibility for multiple small batches or frequent alloy changes: A coreless induction furnace, which can be started cold and completely emptied, is the more appropriate technology.

Understanding these fundamental trade-offs empowers you to select the furnace technology that aligns perfectly with your production goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Up to 98% power efficiency, reducing operational costs. |

| Production Throughput | Ideal for continuous, 24/7 high-volume operations. |

| Metal Quality & Control | Precise temperature control with minimal oxidation. |

| Working Environment | Cleaner and safer with minimal pollutants and noise. |

Ready to optimize your high-volume melting operations? KINTEK specializes in lab equipment and consumables, providing robust solutions for foundries and laboratories. Our expertise in furnace technology can help you achieve unparalleled energy efficiency and superior metal quality. Contact us today to discuss how a core induction furnace can transform your production line!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals