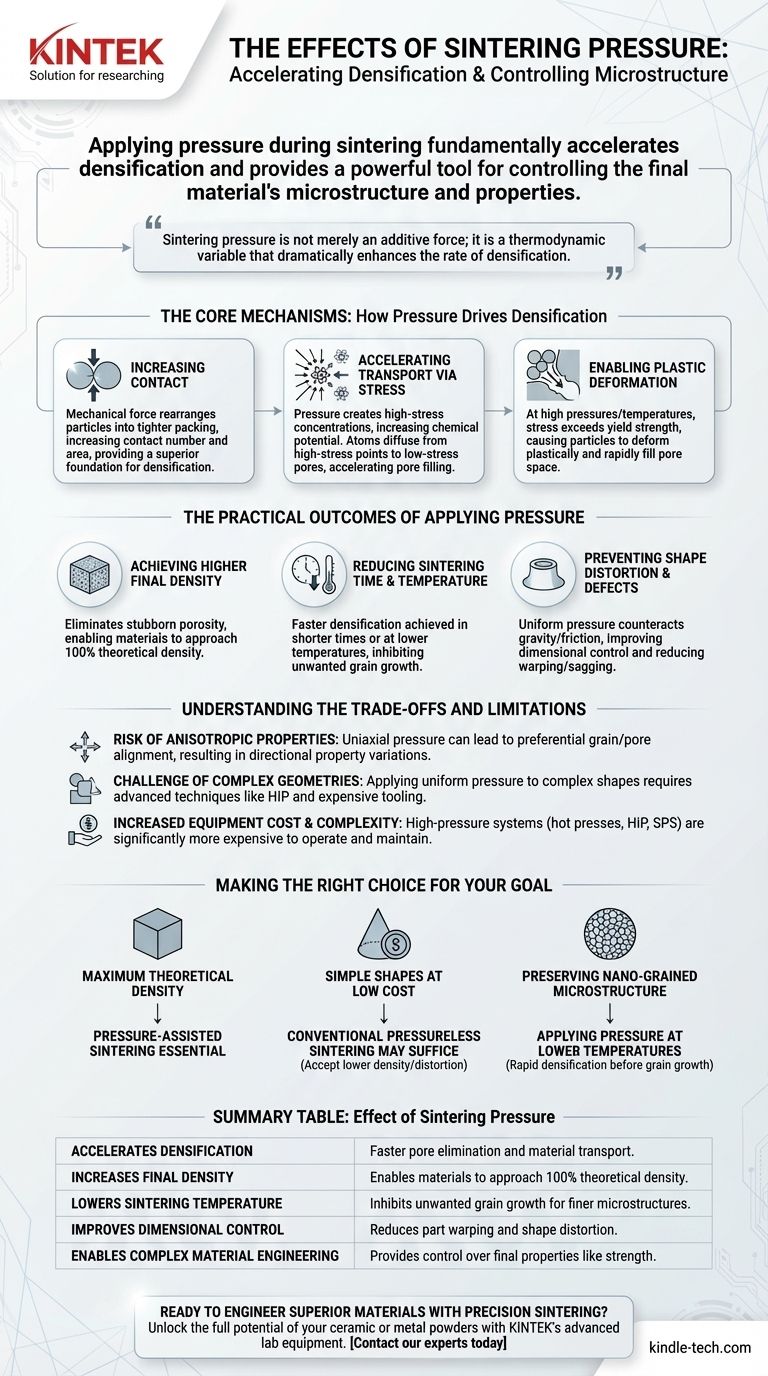

In short, applying pressure during sintering fundamentally accelerates densification and provides a powerful tool for controlling the final material's microstructure and properties. By mechanically forcing particles together, pressure increases the contact area between them and creates stress gradients that serve as a powerful driving force for material transport, leading to faster and more complete pore elimination.

Sintering pressure is not merely an additive force; it is a thermodynamic variable that alters the fundamental driving forces for material transport. By increasing stress at particle contacts, it dramatically enhances the rate of densification, enabling the creation of fully dense materials at lower temperatures and in shorter times than is possible with pressureless methods.

The Core Mechanisms: How Pressure Drives Densification

To understand the effects of pressure, we must look at how it influences the behavior of individual material particles at the microscopic level.

Increasing Particle-to-Particle Contact

The first and most immediate effect of pressure is mechanical. It rearranges and forces powder particles into a tighter packing arrangement.

This dramatically increases the number and area of contact points between adjacent particles. Sintering begins at these contacts, so a larger initial contact area provides a superior foundation for the entire densification process to proceed.

Accelerating Material Transport via Stress

Pressure creates high-stress concentrations at the sharp points where particles touch. This localized stress increases the chemical potential of the atoms in that area.

Driven by this energy difference, atoms diffuse away from the high-stress contact points and deposit into the low-stress regions of the adjacent pores. This process, known as pressure-assisted diffusion, is a far more aggressive mechanism for filling voids than relying on surface tension alone.

Enabling Plastic Deformation

At sufficiently high pressures and temperatures, the stress at particle contacts can exceed the material's yield strength.

This causes the particles themselves to deform plastically, flowing to fill the pore space. This is an extremely rapid densification mechanism that contributes significantly to pore closure, especially in the early and middle stages of sintering.

The Practical Outcomes of Applying Pressure

The microscopic mechanisms of pressure translate directly into tangible, macroscopic benefits for the final component.

Achieving Higher Final Density

Pressure provides the necessary force to eliminate the final, stubborn remnants of porosity that are difficult to remove in pressureless sintering. This allows for the fabrication of materials that approach 100% of their theoretical density.

Reducing Sintering Time and Temperature

Because pressure so effectively accelerates the diffusion and material transport mechanisms, the desired level of density can be achieved much faster or at a significantly lower temperature.

Lowering the sintering temperature is particularly critical for inhibiting unwanted grain growth, allowing for the creation of fine-grained, high-strength materials.

Preventing Shape Distortion and Defects

In conventional (pressureless) sintering, parts can warp, sag, or shrink unevenly due to gravity and friction with the setter plate.

Applying uniform, isostatic pressure counteracts these forces, helping the component maintain its intended shape and reducing the likelihood of defects. This improves dimensional control and final part yield.

Understanding the Trade-offs and Limitations

While powerful, pressure-assisted sintering is not a universal solution. It introduces its own set of challenges that must be considered.

The Risk of Anisotropic Properties

If the pressure is applied uniaxially (from one direction), it can lead to a preferential alignment of grains or pores. This can result in anisotropic mechanical or physical properties, where the material is stronger in one direction than another.

The Challenge of Complex Geometries

Applying uniform pressure to parts with highly complex shapes, internal cavities, or sharp angles can be extremely difficult. Techniques like Hot Isostatic Pressing (HIP) are effective but may require expensive and complex tooling or encapsulation methods.

Increased Equipment Cost and Complexity

Systems capable of applying high pressure at high temperatures (e.g., hot presses, HIP units, or Spark Plasma Sintering machines) are significantly more expensive and complex to operate and maintain than conventional sintering furnaces.

Making the Right Choice for Your Goal

The decision to use pressure depends entirely on the desired outcome for your final component.

- If your primary focus is achieving maximum theoretical density: Pressure-assisted sintering is essential, as it provides the most effective mechanism for eliminating the last remnants of porosity.

- If your primary focus is producing simple shapes at low cost: Conventional pressureless sintering may be sufficient, but you must accept potentially lower density and carefully manage part distortion.

- If your primary focus is preserving a nano-grained microstructure: Applying pressure at lower temperatures is the ideal strategy to densify the material rapidly before significant grain growth can occur.

Ultimately, understanding and controlling pressure allows you to move from simply consolidating a powder to truly engineering a final material.

Summary Table:

| Effect of Sintering Pressure | Key Benefit |

|---|---|

| Accelerates Densification | Faster pore elimination and material transport. |

| Increases Final Density | Enables materials to approach 100% theoretical density. |

| Lowers Sintering Temperature | Inhibits unwanted grain growth for finer microstructures. |

| Improves Dimensional Control | Reduces part warping and shape distortion. |

| Enables Complex Material Engineering | Provides control over final properties like strength. |

Ready to Engineer Superior Materials with Precision Sintering?

Unlock the full potential of your ceramic or metal powders. KINTEK's advanced lab equipment, including hot presses and sintering furnaces, provides the precise pressure and temperature control you need to achieve maximum density, fine microstructures, and superior material properties.

Contact our experts today to discuss how our solutions can optimize your sintering process and help you create high-performance materials.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why is a vacuum essential for sintering metal-ceramic composites? Achieve Pure, High-Density Results

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes