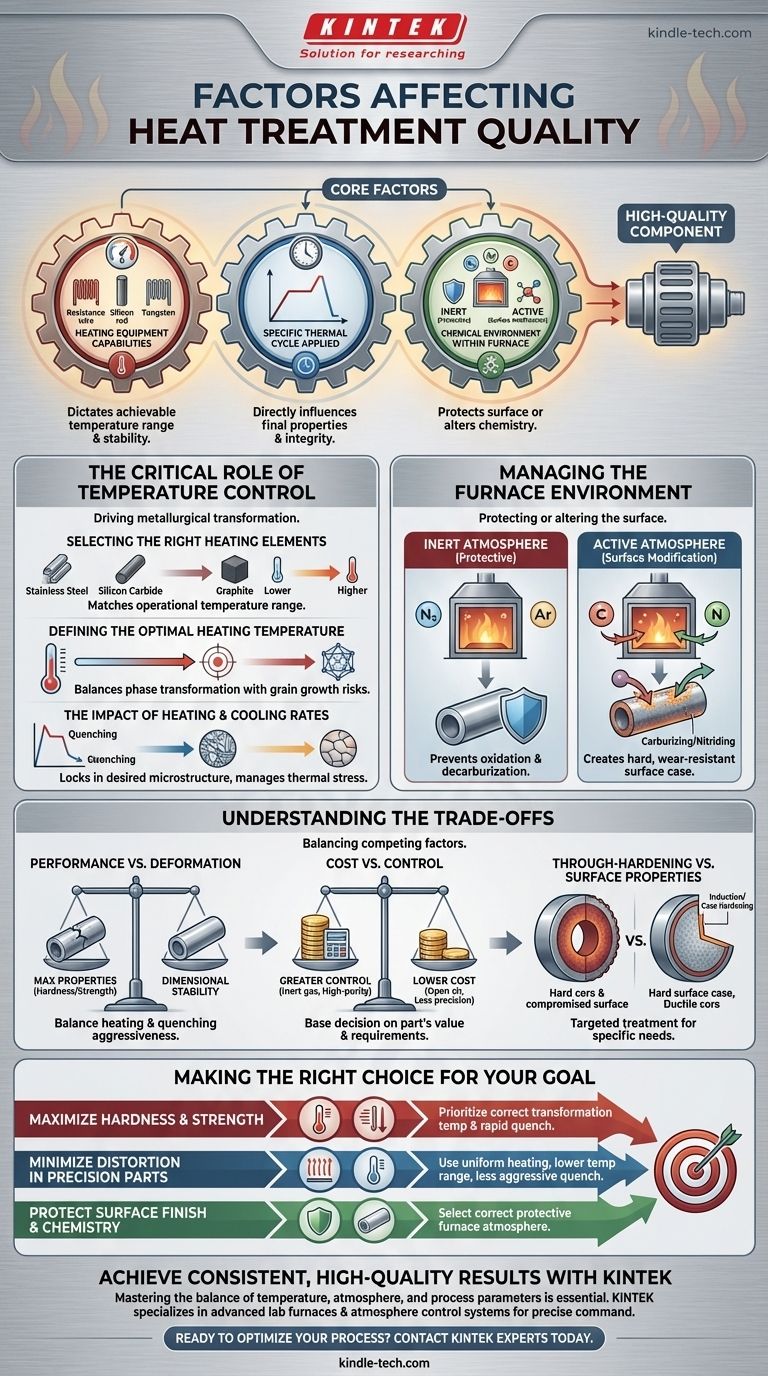

At its core, achieving high-quality heat treatment depends on the precise control of three fundamental factors: the heating equipment's capabilities, the specific thermal cycle applied, and the chemical environment within the furnace. The selection of heating elements dictates the achievable temperature range, while the exact heating temperature and the furnace atmosphere directly influence the final properties and integrity of the workpiece.

The quality of a heat-treated component is not determined by a single setting, but by the successful orchestration of a complete thermal and chemical system. True control comes from understanding how temperature, time, and atmosphere interact to transform a material to meet its specific performance requirements.

The Critical Role of Temperature Control

Temperature is the primary driver of metallurgical transformation. However, achieving the desired outcome is about more than simply reaching a target number; it requires a deep understanding of the equipment, the material's response, and the full thermal profile.

Selecting the Right Heating Elements

The physical hardware of the furnace is the foundation of the process. The choice of heating elements directly determines the operational temperature range and stability.

Elements like stainless steel tubes and resistance wires are suitable for lower temperature ranges. For higher temperatures, materials such as silicon carbon rods, silicon molybdenum rods, or even graphite and tungsten are necessary.

Matching the heating element to the required process temperature ensures the furnace can reliably reach and maintain the target heat without failure, providing a stable foundation for a repeatable process.

Defining the Optimal Heating Temperature

The specific heating temperature is selected based on the material's properties and the desired final performance. It is a critical parameter that dictates the microstructural changes within the metal.

For example, in steel, this temperature must be high enough to achieve the desired phase transformation (e.g., austenitization) but not so high that it causes excessive grain growth, which can make the material brittle.

The goal is to find the precise temperature that unlocks the required performance—like hardness or strength—while minimizing negative side effects.

The Impact of Heating and Cooling Rates

The quality of heat treatment is also heavily influenced by the rate of temperature change. This includes how quickly the part is heated, how long it is held at the target temperature (soaking), and, most critically, how quickly it is cooled (quenching).

A slow heating rate can help reduce thermal stress in complex parts, while the soaking time ensures the entire cross-section of the part reaches a uniform temperature for a complete transformation. The cooling rate is often the most critical step, as it locks in the desired microstructure.

Managing the Furnace Environment

The atmosphere inside the furnace plays a crucial role in protecting the part's surface or, in some cases, intentionally altering its chemistry. This environment must be deliberately chosen and controlled.

Choosing the Correct Furnace Atmosphere

The furnace atmosphere can be either inert or active. The choice depends entirely on the material being treated and the goals of the process.

An inert atmosphere, using gases like argon or nitrogen, is protective. Its purpose is to prevent unwanted chemical reactions, such as oxidation (scaling) or decarburization, which can ruin the surface of the component.

An active atmosphere is used to intentionally change the surface chemistry of a part. Processes like carburizing (adding carbon) or nitriding (adding nitrogen) use reactive gases to create a hard, wear-resistant surface case.

Understanding the Trade-offs

Every heat treatment decision involves balancing competing factors. Recognizing these trade-offs is key to avoiding common pitfalls and optimizing the process for a specific application.

Performance vs. Deformation

There is often a direct trade-off between achieving maximum mechanical properties and maintaining dimensional stability.

Higher heating temperatures or more aggressive quenching can produce superior hardness and strength. However, these same conditions also introduce significant thermal stress, increasing the risk of warping, distortion, and cracking, especially in complex or thin-walled parts.

Cost vs. Control

Greater process control almost always comes at a higher cost. A high-purity inert gas atmosphere provides excellent protection against oxidation but is more expensive than using endothermic gas or simply heating in open air.

The decision must be based on the part's value and its service requirements. A critical aerospace component justifies the cost of a highly controlled process, whereas a simple, non-critical part may not.

Through-Hardening vs. Surface Properties

The goals for the core of the material may conflict with the goals for its surface. An aggressive quench needed to fully harden the core of a large component can compromise its surface finish or dimensional accuracy.

This is why processes like induction hardening or case hardening were developed—they allow for targeted treatment of the surface without affecting the entire part, offering a solution to this trade-off.

Making the Right Choice for Your Goal

To achieve consistent, high-quality results, align your heat treatment parameters with the primary objective for the component.

- If your primary focus is maximizing hardness and strength: Prioritize reaching the correct transformation temperature and employing a sufficiently rapid quench to lock in the desired hard microstructure.

- If your primary focus is minimizing distortion in precision parts: Use uniform heating methods, operate at the lower end of the acceptable temperature range, and select a less aggressive quenching medium.

- If your primary focus is protecting surface finish and chemistry: The most critical factor is selecting the correct protective furnace atmosphere to prevent oxidation and decarburization.

Mastering these interconnected factors grants you direct control over the final performance and reliability of your components.

Summary Table:

| Factor | Key Considerations | Impact on Quality |

|---|---|---|

| Temperature Control | Heating element type, target temperature, heating/cooling rates | Drives metallurgical transformations; affects hardness, strength, and microstructure. |

| Furnace Atmosphere | Inert (protective) vs. Active (surface modification) | Prevents oxidation/decarburization or enables processes like carburizing/nitriding. |

| Process Parameters | Soaking time, quenching method, thermal cycle | Determines uniformity, dimensional stability, and risk of warping or cracking. |

| Material & Goal Alignment | Part geometry, desired properties (core vs. surface) | Balances performance requirements with manufacturability and cost. |

Achieve Consistent, High-Quality Results with KINTEK

Mastering the delicate balance of temperature, atmosphere, and process parameters is essential for successful heat treatment. Whether your goal is maximizing hardness, minimizing distortion in precision parts, or protecting surface integrity, the right equipment is the foundation of control and repeatability.

KINTEK specializes in advanced lab furnaces and atmosphere control systems designed to give you precise command over every critical factor. Our solutions help laboratory professionals and manufacturers eliminate guesswork, reduce scrap, and ensure every component meets its exact performance specifications.

Ready to optimize your heat treatment process?

Contact our experts today to discuss your specific application needs. Let us help you select the perfect furnace and atmosphere solution to achieve superior results for your materials.

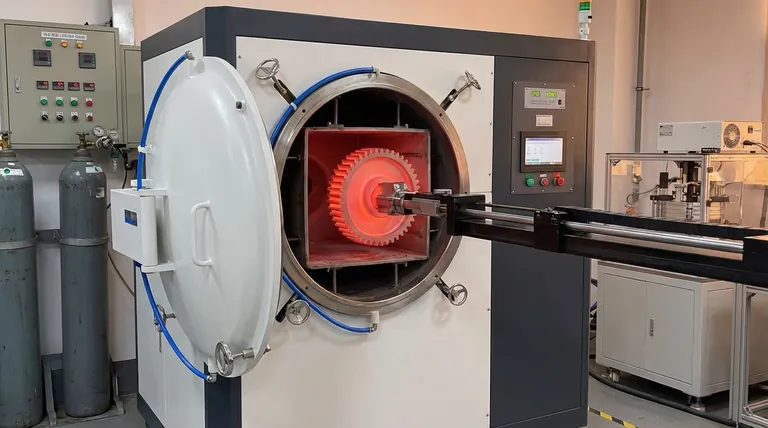

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the latest technologies in additive manufacturing? From Prototyping to Mass Production

- What are some challenges for biofuels? Overcoming Key Hurdles to Renewable Energy

- What are the limitations of physical vapor deposition? Overcoming the Line-of-Sight Challenge

- What is a general purpose laboratory oven? A Guide to Drying, Sterilizing, and Curing

- What pressure is sputter coating? Master the 1-100 mTorr Range for Perfect Films

- How does a high-precision oven contribute to the post-processing of hydrothermal oxidation products? Ensure Data Purity

- What are the three types of tempering? Choose the Right Process for Hardness vs. Toughness

- What is the process of vim var melting? Master Vim Variable Scopes for Bug-Free Scripting