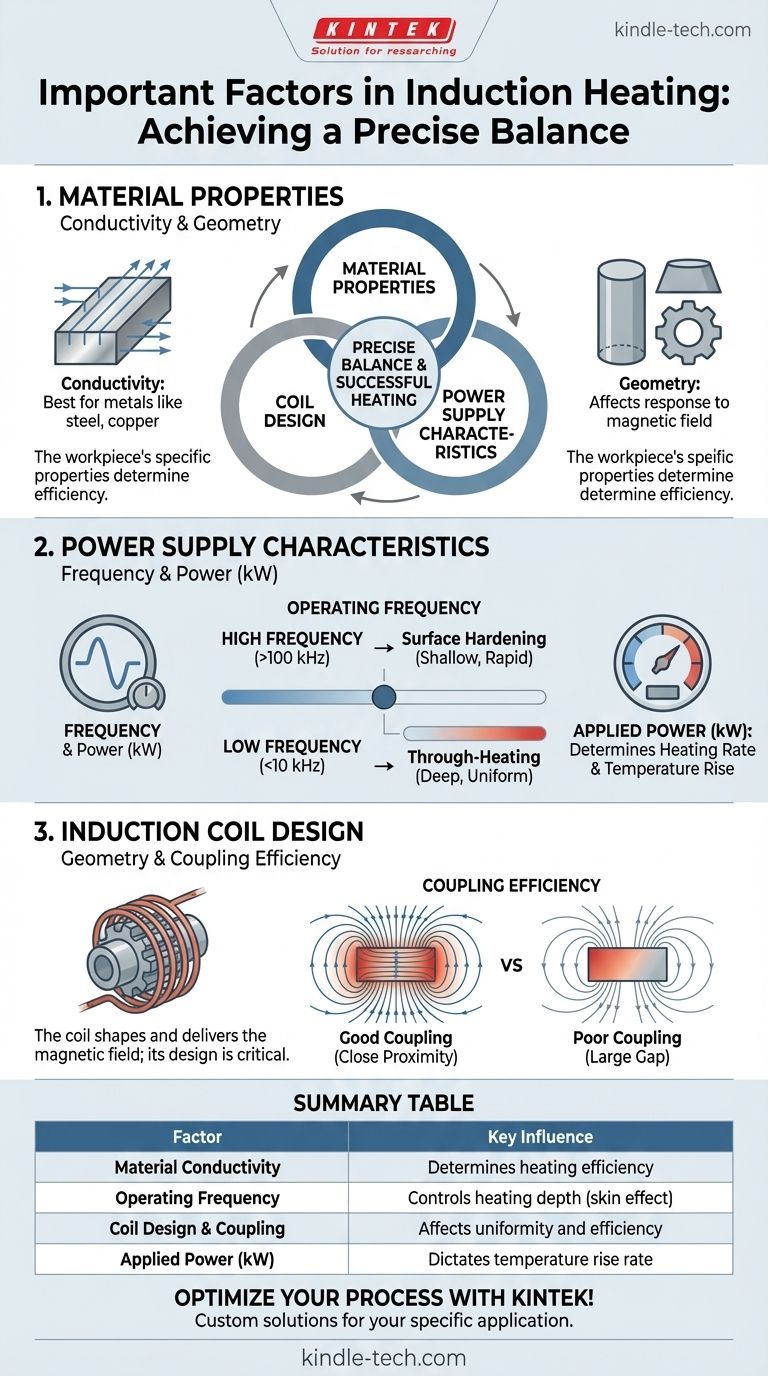

At its core, successful induction heating depends on a precise balance of three main areas: the properties of the material being heated, the design of the induction coil, and the characteristics of the power supply. Key factors include your part's material, the required heating depth, operating frequency, applied power, coil design, and the coupling distance between the coil and the part.

The effectiveness of an induction heating system is not determined by a single factor, but by the strategic interplay between the workpiece, the induction coil, and the power supply. Understanding how these elements interact is the key to achieving a rapid, controlled, and efficient heating process.

The Core Principle: How Induction Heating Works

Induction heating is a non-contact process that uses electromagnetic principles to generate heat directly inside a conductive material. This internal heating method is what makes it so fast and clean.

Electromagnetic Induction

An induction heating system uses a power supply to send a strong alternating current through a copper coil, often called an inductor. This current creates a powerful and rapidly changing magnetic field around the coil.

The Joule Effect

When a conductive part (the workpiece) is placed within this magnetic field, the field induces circulating electrical currents inside the part. These are known as eddy currents. The material's natural resistance to the flow of these currents generates intense, localized heat—a phenomenon called the Joule effect.

Key Factors Influencing Your Heating Process

Optimizing your process requires a clear understanding of several interconnected variables. The right choice for one factor will directly influence the requirements for the others.

The Workpiece Material

The electrical conductivity of your material is the most fundamental factor. Induction heating is most effective on conductive metals like steel, copper, and aluminum. The specific properties of the metal determine how efficiently it will respond to the magnetic field.

Heating Depth and Operating Frequency

The operating frequency of the power supply is the single most important variable for controlling how deeply the heat penetrates the part. This is known as the skin effect.

A high frequency (e.g., >100 kHz) concentrates the eddy currents near the surface, resulting in shallow, rapid heating. This is ideal for applications like surface hardening.

A low frequency (e.g., <10 kHz) allows the magnetic field to penetrate deeper into the part, generating heat more uniformly throughout its cross-section. This is used for through-heating applications like forging or annealing.

Applied Power and Temperature Rise

The power of the supply, measured in kilowatts (kW), determines the rate of heating. More power means more energy is delivered to the workpiece per second, resulting in a faster temperature rise. The required power is calculated based on the mass of the part, the material's properties, and the desired time to reach the target temperature.

The Critical Role of the Induction Coil

The induction coil is the "tool" that shapes and delivers the magnetic field to the workpiece. Its design is often the most customized component of the system and has a massive impact on the final result.

Coil Design and Geometry

The coil must be designed to match the geometry of the part being heated. A simple solenoid coil works for cylindrical parts, but complex shapes require custom-designed coils to ensure the magnetic field is applied evenly to the desired areas.

Coupling Efficiency

Coupling refers to the proximity of the coil to the workpiece. A smaller gap between the coil and the part results in a stronger magnetic field transfer and more efficient heating. Poor coupling wastes energy and leads to slower, less precise heating.

Understanding the Trade-offs and System Limitations

While powerful, induction heating is not a universal solution. Its effectiveness depends entirely on a well-designed system where every component works in harmony.

Efficiency is Not Guaranteed

High efficiency is a major benefit of induction heating, but it depends on correctly matching the power supply frequency, coil design, and coupling distance to the part's material and geometry. A mismatch in any of these areas will drastically reduce overall efficiency.

Ancillary Systems and Footprint

A complete induction system includes more than just the power supply and coil. A chiller is almost always required to cool the copper coil, which can get extremely hot. The physical space required for the power supply, chiller, and workstation must be considered in your facility planning.

Matching the System to Your Application

Your specific heating goal is the ultimate guide for selecting and configuring your system. Consider the primary outcome you need to achieve.

- If your primary focus is surface hardening: You will need a high-frequency power supply and a precisely designed coil that maintains a close, consistent coupling distance to the part's surface.

- If your primary focus is through-heating for forging or annealing: You should opt for a lower-frequency, high-power system to ensure the heat penetrates deep into the material's core.

- If your primary focus is heating complex shapes or specific zones: Success depends almost entirely on a custom-engineered coil designed to mirror the part's geometry and direct the magnetic field only where it is needed.

Ultimately, mastering induction heating is about controlling the flow of energy by aligning the physics of the process with the goals of your application.

Summary Table:

| Factor | Key Influence | Application Example |

|---|---|---|

| Material Conductivity | Determines heating efficiency | Best for conductive metals like steel, copper |

| Operating Frequency | Controls heating depth (skin effect) | High frequency for surface hardening |

| Coil Design & Coupling | Affects heating uniformity and efficiency | Custom coils for complex part geometries |

| Applied Power (kW) | Dictates the rate of temperature rise | High power for fast through-heating |

Optimize your induction heating process with KINTEK!

Choosing the right equipment is critical for achieving rapid, controlled, and efficient heating. KINTEK specializes in high-performance lab equipment, including induction heating systems tailored to your specific material and application needs—from surface hardening to through-heating.

Our experts can help you select the perfect power supply, design a custom coil for optimal coupling, and ensure your entire system operates at peak efficiency.

Ready to enhance your lab's capabilities? Contact our team today to discuss your project and discover the KINTEK difference.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why does a vacuum hot pressing furnace achieve higher thermal conductivity than SPS for diamond-aluminum composites?

- What technical advantages does a vacuum hot press furnace offer? Achieve Superior Densification in Al-Si Composites

- How does vacuum hot pressing equipment improve the densification of metal-matrix composites? Achieve Over 90% Density

- Why is a vacuum hot press required for plasma-sprayed Ti-Al-V alloy? Achieve Full Densification & Stability

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?