At its core, a vacuum press is a specialized clamping system. It is used to laminate flat and curved panels, apply veneer, and form composites by using uniform atmospheric pressure to press objects together with immense, even force. Its applications range from fine woodworking and antique restoration to fabricating skateboards and carbon fiber parts.

A vacuum press isn't just for specific tasks; it's a method for achieving perfectly uniform clamping pressure. By removing air from a sealed bag, it harnesses the weight of the atmosphere to apply flawless force over complex shapes, something impossible to achieve with traditional mechanical clamps.

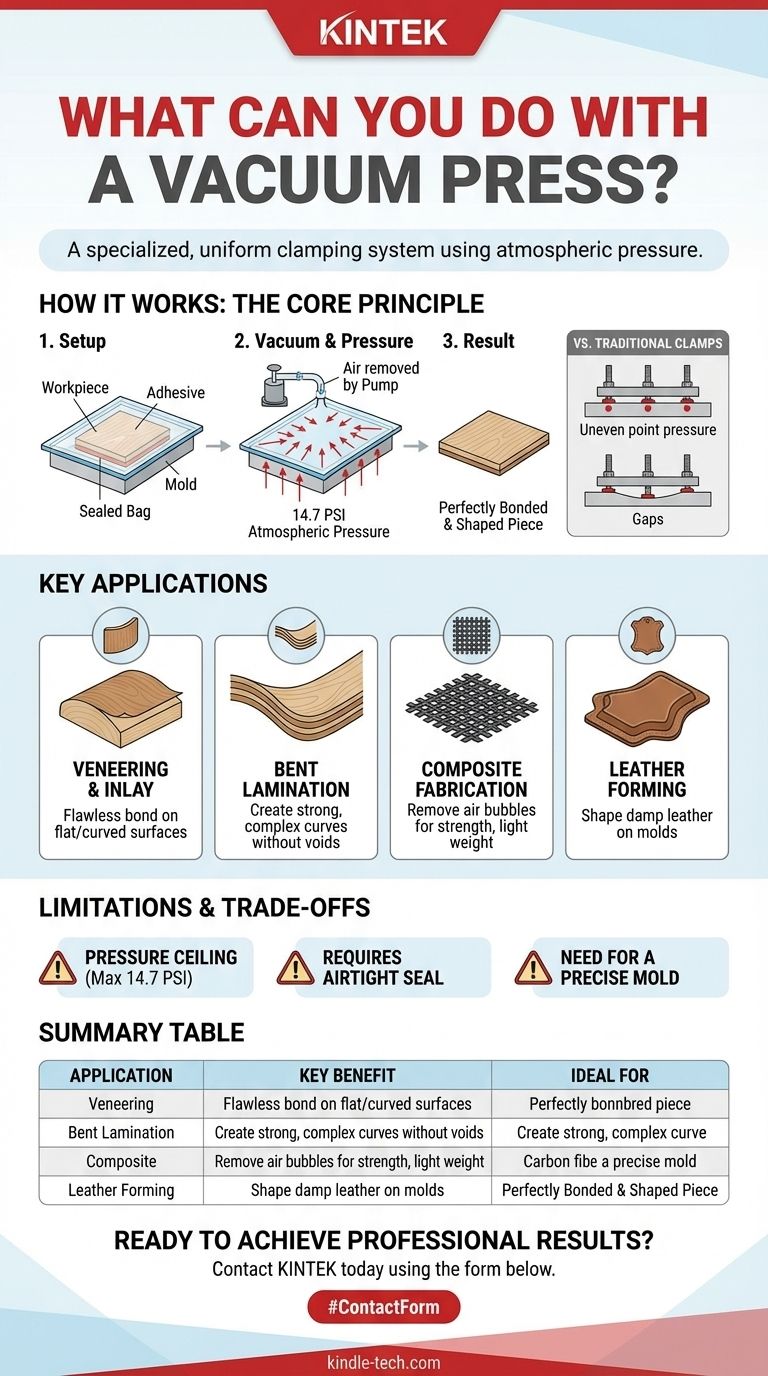

The Core Principle: Clamping with Air Pressure

Understanding how a vacuum press works is the key to seeing its true potential. It's a simple but powerful concept that goes far beyond a simple list of applications.

How a Vacuum Press Works

The system consists of a heavy-duty vinyl or polyurethane bag, a pump, and a hose. A workpiece, typically coated in an adhesive like wood glue or resin, is placed inside the bag along with a mold or form.

The bag is sealed, and the pump evacuates the air from inside. This creates a vacuum, and the atmospheric pressure outside the bag—approximately 14.7 pounds per square inch (PSI)—exerts force evenly across the entire surface of the workpiece, pressing it firmly against its mold.

The Advantage of Uniform Pressure

Traditional clamps, like C-clamps or bar clamps, apply pressure only at specific points. This can lead to uneven glue lines, gaps in lamination, or starved joints where too much glue is squeezed out.

A vacuum press eliminates these issues. The pressure is perfectly distributed, ensuring a complete and consistent bond across the entire surface, whether it's a flat panel or a complex, three-dimensional curve.

Key Applications in Woodworking and Fabrication

The principle of uniform pressure makes the vacuum press an essential tool for a wide variety of precision work.

Veneering and Inlay

This is a primary application. A vacuum press can apply veneer to flat substrates flawlessly, but its real strength is in veneering curved objects like custom cabinet doors, dashboards, or furniture components. It's also ideal for delicate inlay work where even pressure is critical to avoid damaging the piece.

Bent Lamination and Forming Curves

Creating strong, curved wooden parts is simple with a vacuum press. Thin strips of wood are glued and placed over a form inside the bag. The press holds the strips in perfect alignment as the glue cures, creating a single, solid curved component for projects like chair parts or curved stairway stringers.

Working with Composites

For materials like carbon fiber, fiberglass, or Kevlar, a vacuum press is fundamental. The process, known as vacuum bagging, uses pressure to consolidate the layers of composite material and resin. It effectively removes all trapped air bubbles, ensuring the resin fully saturates the fabric, which results in a significantly stronger and lighter finished part.

Forming Other Materials

The versatility of the press extends beyond wood and composites. It can be used for tasks like wet-forming leather, where damp leather is pressed onto a mold to give it a specific, rigid shape once it dries.

Understanding the Trade-offs and Limitations

While incredibly versatile, a vacuum press is not the right tool for every job. Understanding its limitations is crucial for success.

Pressure Ceilings

A vacuum press is limited by atmospheric pressure. At sea level, the maximum achievable pressure is about 14.7 PSI. This is more than enough for laminating and veneering, but it is significantly less than the thousands of pounds of force exerted by a hydraulic press.

The Importance of the Bag and Seal

The entire system is dependent on an airtight environment. Any leak in the vacuum bag or a poor seal will cause the pump to run continuously and prevent the system from reaching full pressure, compromising the bond.

You Still Need a Mold

A vacuum press conforms a material to a shape; it does not create the shape itself. You must first build a precise, solid mold or form. The quality of your finished piece can only be as good as the quality of the mold it was pressed against.

Is a Vacuum Press Right for Your Project?

Choosing the right tool depends entirely on your goal. A vacuum press excels where uniform pressure over a large or complex surface is the priority.

- If your primary focus is high-end woodworking and veneering: It is an indispensable tool for achieving flawless, professional-grade results on both flat and curved surfaces.

- If your primary focus is creating strong, curved parts: A vacuum press is the most effective and reliable method for bent lamination, ensuring consistent curves without voids.

- If your primary focus is composite fabrication: It is a foundational technique for creating strong, lightweight parts by ensuring complete resin saturation and eliminating air pockets.

By understanding that a vacuum press is fundamentally a better way to clamp, you can apply its principle to solve a vast range of creative and technical challenges.

Summary Table:

| Application | Key Benefit | Ideal For |

|---|---|---|

| Veneering & Inlay | Uniform pressure prevents gaps | Curved furniture, cabinets |

| Bent Lamination | Holds complex curves perfectly | Chair parts, stair stringers |

| Composite Fabrication | Removes air bubbles for strength | Carbon fiber, fiberglass parts |

| Leather Forming | Shapes damp leather onto molds | Custom leather goods |

Ready to achieve professional-grade results with a vacuum press?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including reliable vacuum press systems perfect for woodworking, composite fabrication, and more. Our solutions help you eliminate air bubbles, ensure even adhesive distribution, and create flawless laminations every time.

Contact us today using the form below to discuss your specific needs and discover how KINTEK can enhance your workshop's capabilities.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity