In short, pressureless compaction is a set of techniques used to form dense objects from metal or ceramic powders without applying high external mechanical force. Instead of pressing the powder in a die, these methods rely on principles like vibration, liquid suspension, or controlled particle size distribution to encourage the powder to pack itself into a dense arrangement before it is fused together through sintering.

The central idea behind pressureless compaction is achieving high density through intelligent particle arrangement rather than brute force. Success depends critically on controlling the powder's characteristics, especially the mix of particle sizes, to minimize empty space.

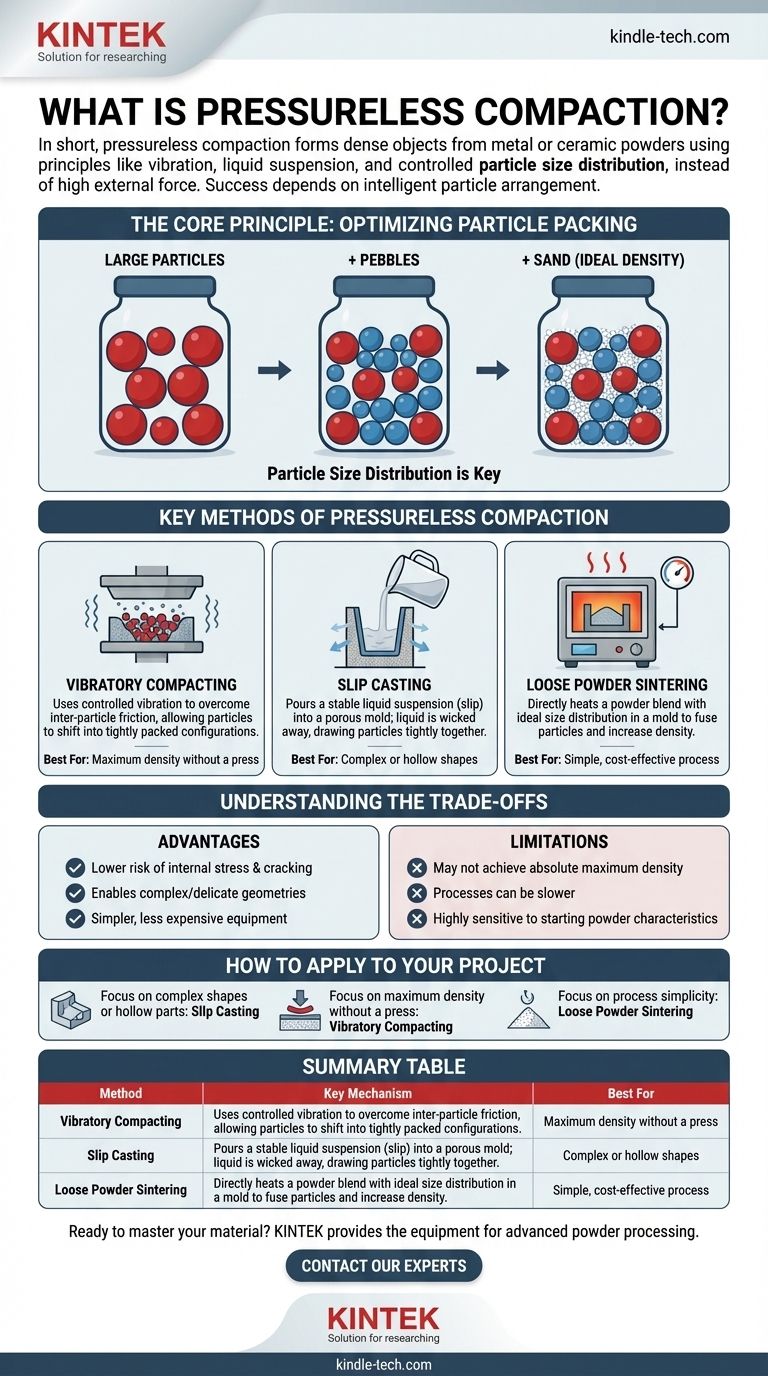

The Core Principle: Optimizing Particle Packing

Traditional compaction uses immense pressure to force powder particles together, crushing them and reducing the voids between them. Pressureless methods achieve a similar outcome through more subtle means.

The Importance of Particle Size Distribution

The single most important factor is the size distribution of the powder particles. A powder composed of uniformly sized spheres can only pack to a certain density, leaving significant empty space (interstitial voids) between them.

By using a carefully engineered mix of large, medium, and small particles, the smaller particles can fill the voids left between the larger ones. This dramatically increases the "tap density" or packed density of the loose powder before it's even heated.

An Analogy: A Jar of Rocks

Imagine filling a glass jar with large rocks. You will see many large gaps. To make the contents denser, you don't press the rocks harder; you pour in smaller pebbles that fill the gaps. To increase density further, you add sand, which fills the even smaller gaps between the pebbles. This is the exact principle behind pressureless compaction.

Key Methods of Pressureless Compaction

The reference material points to three primary methods, each leveraging the principle of particle packing in a unique way.

Vibratory Compacting

In this method, a mold is filled with a powder blend that has an optimized particle size distribution. The entire mold is then subjected to controlled vibration.

This vibration provides the energy needed to overcome inter-particle friction, allowing the particles to shift and settle into their most tightly packed configuration. The smaller particles naturally work their way into the gaps between the larger ones.

Slip Casting

Slip casting involves creating a stable liquid suspension of the powder, known as a slip. This slip is poured into a porous mold, typically made of plaster.

The porous mold draws the liquid out of the slip via capillary action. As the liquid is wicked away, the powder particles are drawn tightly against the mold wall and each other, resulting in a dense, uniformly packed "green" part that can be removed and sintered.

Loose Powder Sintering

This is the most direct method. A powder with an ideal size distribution is simply placed into a mold or crucible without any applied pressure.

The entire assembly is then heated in a furnace for sintering. While the initial density is lower than in other methods, a well-designed powder blend can still achieve high final densities as the particles fuse together and the component shrinks during the heating process.

Understanding the Trade-offs

Choosing a pressureless method requires understanding its distinct advantages and limitations compared to traditional high-pressure compaction.

The Primary Advantages

The main benefit is the avoidance of high pressure, which leads to several advantages. There is a lower risk of internal stress and cracking in the final part. It also allows for the creation of more complex or delicate geometries that would be impossible to form in a rigid die. Finally, the required equipment is often simpler and less expensive than large industrial presses.

Potential Limitations

Pressureless techniques may not achieve the absolute maximum densities possible with extreme isostatic pressing. The processes can be slower and are highly sensitive to the starting powder's characteristics. Achieving consistent results requires significant expertise in materials science to control particle size, shape, and distribution.

How to Apply This to Your Project

The best method depends entirely on the specific requirements of your component.

- If your primary focus is creating complex shapes or hollow parts: Slip casting is the ideal choice due to its use of a liquid medium and a mold.

- If your primary focus is achieving maximum density without a press: Vibratory compacting with a meticulously optimized powder blend is your most effective option.

- If your primary focus is process simplicity for basic geometries: Loose powder sintering can be a viable and cost-effective route, provided you can control the initial powder packing.

Ultimately, mastering pressureless compaction is about controlling your material from the very first particle.

Summary Table:

| Method | Key Mechanism | Best For |

|---|---|---|

| Vibratory Compacting | Uses vibration to pack particles | Maximum density without a press |

| Slip Casting | Liquid suspension in a porous mold | Complex or hollow shapes |

| Loose Powder Sintering | Direct heating of powder in a mold | Simple, cost-effective process |

Ready to master your material from the first particle?

Pressureless compaction techniques require precise control over powder characteristics to achieve high-density, complex parts. KINTEK specializes in providing the high-quality lab equipment and consumables needed for advanced powder processing and sintering.

Whether you are developing new materials or optimizing your manufacturing process, our expertise can help you achieve consistent, reliable results.

Contact our experts today to discuss how we can support your pressureless compaction projects.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- What are the advantages and disadvantages of transfer moulding? Achieve Precision for Complex Thermoset Parts

- Why is a laboratory hydraulic press used for refractory bricks? Achieve Peak Green Body Density and Strength

- What is the system of a hydraulic press? Harnessing Pascal's Law for Immense Force

- What role does a laboratory manual hydraulic press play in the preparation of salt pellets? Ensure Research Precision

- What are the hazards of press machine? Mitigate Crushing, Amputation, and Other Critical Risks

- What is KBr pellet technique? Master Solid Sample FTIR Analysis with Clear Pellets

- Which material is used in a hydraulic press? The Role of High-Strength Steel and Hydraulic Fluid

- Why was the hydraulic press important? Unlocking Unprecedented Industrial Power