The primary advantage of a quartz heater is its ability to deliver instant, direct heat. Unlike heaters that warm the surrounding air, a quartz heater emits infrared radiation that travels through the air until it hits an object or a person. This process provides an immediate sensation of warmth exactly where it is aimed, making it exceptionally effective for targeted heating.

A quartz heater excels at providing immediate, focused warmth for a person or a small area, much like the sun warming you on a cool day. However, it is fundamentally inefficient at raising the ambient temperature of an entire room. Understanding this distinction is the key to choosing the right tool for your heating needs.

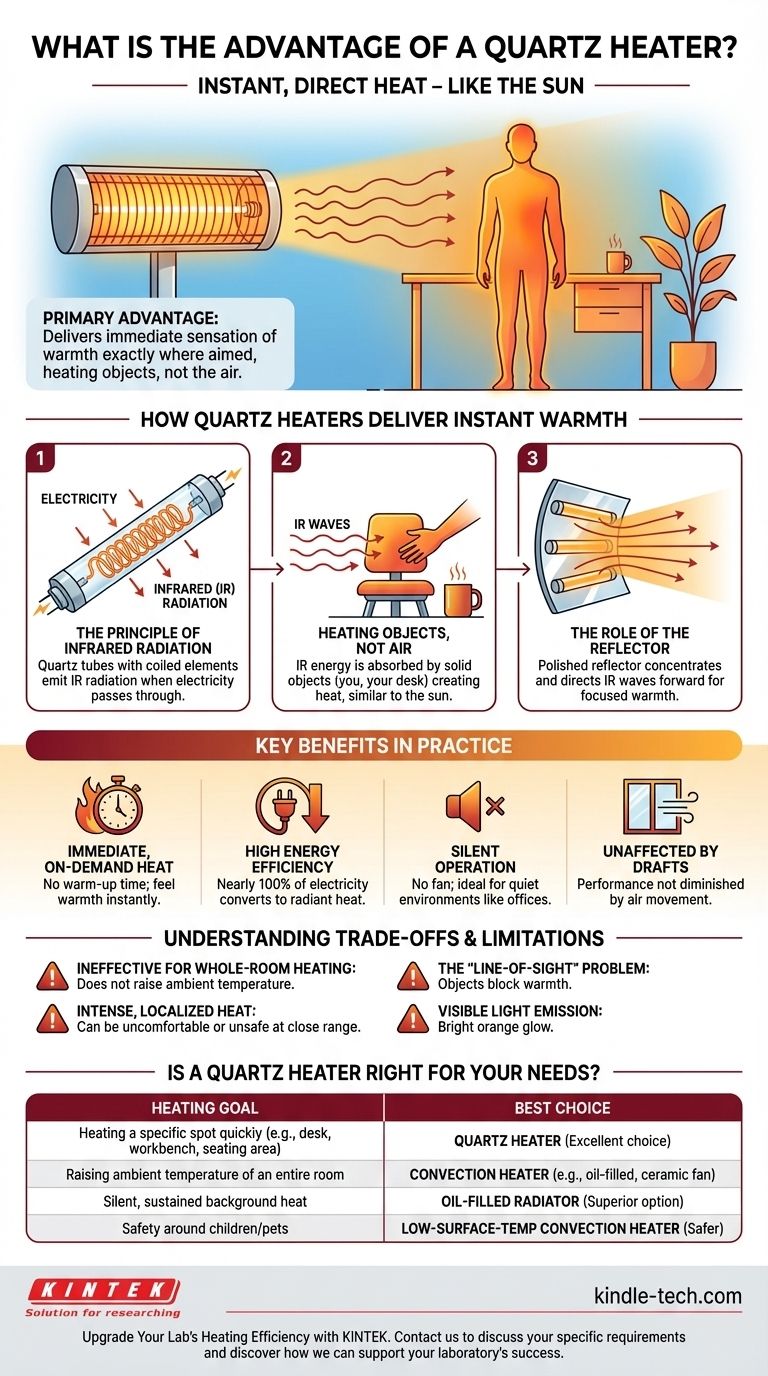

How Quartz Heaters Deliver Instant Warmth

To understand the advantages of a quartz heater, you must first understand its method of heat transfer. It operates on a principle fundamentally different from most common space heaters.

The Principle of Infrared Radiation

At the core of a quartz heater is one or more quartz tubes containing a coiled wire element. When electricity passes through the element, it heats up and emits infrared (IR) radiation.

The quartz tube itself does not produce the heat; it simply protects the heating element and allows the IR waves to pass through efficiently and safely.

Heating Objects, Not Air

This infrared energy travels in a straight line until it is absorbed by a solid object, such as you, your desk, or the floor. This absorption of energy is what you perceive as heat.

This is the same principle as the sun. On a cool but sunny day, you feel warm in the direct sunlight because the sun's IR waves are warming your body, even if the air temperature is low. A quartz heater replicates this effect on a smaller scale.

The Role of the Reflector

Most quartz heaters feature a polished, reflective surface behind the tubes. This reflector's job is to concentrate and direct the infrared waves forward, focusing the heat into a specific zone. This makes the warmth highly directional.

Key Benefits in Practice

The unique mechanism of a quartz heater translates into several practical benefits for specific applications.

Immediate, On-Demand Heat

Because it does not need to heat the air in a room, there is no warm-up time. The moment you turn on a quartz heater, you begin to feel its warmth, provided you are in its line of sight.

High Energy Efficiency

Quartz heaters are highly efficient at converting electricity into radiant heat. Nearly 100% of the electrical energy used is transformed directly into infrared energy. Very little is wasted in the process of delivering warmth to a target.

Silent Operation

Most quartz heaters do not use a fan. The heat radiates outward naturally. This results in completely silent operation, making them ideal for quiet environments like offices or bedrooms where the noise of a fan heater would be disruptive.

Unaffected by Drafts

Since a quartz heater warms objects directly, its effectiveness is not easily diminished by drafts or air movement. Convection heaters that warm the air can have their efforts quickly undone by a cold draft from a window or door.

Understanding the Trade-offs and Limitations

No technology is without its drawbacks. The strengths of a quartz heater are directly linked to its weaknesses in other areas.

Ineffective for Whole-Room Heating

This is the most critical limitation. Because quartz heaters do not heat the air, they will not raise the ambient temperature of a room. The moment you move out of its direct path or turn it off, the sensation of warmth vanishes instantly.

Intense, Localized Heat

The heat produced can be very intense at close range. Objects placed too close to the heater can become a fire hazard, and the direct heat can be uncomfortable or even unsafe for prolonged, close-quarters exposure.

The "Line-of-Sight" Problem

You must be in the heater's direct path to feel its effect. If an object, like a chair or desk leg, is between you and the heater, it will block the infrared waves, and you will feel no warmth.

Visible Light Emission

The heating elements in a quartz heater glow a bright orange. While some find this glow pleasant, others may find the light distracting, especially in a dark environment like a bedroom at night.

Is a Quartz Heater Right for Your Needs?

Your decision should be based entirely on your specific heating goal. By correctly identifying your need, you can choose the most effective and efficient technology.

- If your primary focus is heating a specific spot quickly: A quartz heater is an excellent choice for a personal workspace, garage workbench, or a targeted seating area.

- If your primary focus is raising the ambient temperature of an entire room: You should consider a convection heater, such as an oil-filled radiator or a ceramic fan heater.

- If your primary focus is silent, sustained background heat: An oil-filled radiator is a superior option, though it is much slower to initially heat the space.

- If your primary focus is safety around children or pets: A low-surface-temperature convection heater is often a safer choice due to the intense, exposed heat of a quartz element.

By matching the heating technology to your specific goal, you ensure both effective comfort and energy efficiency.

Summary Table:

| Advantage | Description |

|---|---|

| Instant Heat | No warm-up time; provides immediate warmth upon activation. |

| Targeted Heating | Focuses infrared energy on specific objects or people, not the air. |

| High Energy Efficiency | Converts nearly 100% of electricity into direct radiant heat. |

| Silent Operation | No fan required, making it ideal for quiet environments. |

| Unaffected by Drafts | Performance is not diminished by air movement or open spaces. |

Upgrade Your Lab's Heating Efficiency with KINTEK

Just as a quartz heater delivers precise, on-demand warmth, KINTEK provides targeted solutions for your laboratory's heating needs. Whether you require precise temperature control for experiments or reliable heating for sample preparation, our range of high-quality lab equipment is designed for maximum efficiency and performance.

Let our experts help you select the perfect heating solution to enhance your workflow and ensure accurate results. Contact KINTEK today to discuss your specific requirements and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Infrared Heating Quantitative Flat Plate Press Mold

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is the working temperature of a heating element? Match Material to Your Application's Heat Needs

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- Are heating elements safe? Ensuring Reliable and Secure Thermal Processing

- How do PTC fan heaters work? Discover Efficient Space Heating Solutions for Labs & Offices

- How long does a heating element last on the furnace? Understand Lifespan & Safety for Your System

- Can a heating element overheat? The Critical Causes and Safety Risks Explained

- What is the crystal structure of MoSi2? Unlocking Its High-Temperature Performance

- What are the pros and cons of molybdenum? Harness Its High-Temperature Power