In short, a burnout furnace is a high-temperature oven designed for precision. Its primary function is to heat materials in a highly controlled and clean environment to "burn out," or eliminate, unwanted combustible materials from a mold or other workpiece. This is achieved through programmable temperature cycles that ensure a thorough, uniform, and damage-free process.

The crucial insight is that a burnout furnace isn't just about generating heat; it's about executing a precise thermal program. Its purpose is to create a perfect, clean void or to treat a material without contaminating it, which is essential for processes like investment casting, ashing, and certain heat treatments.

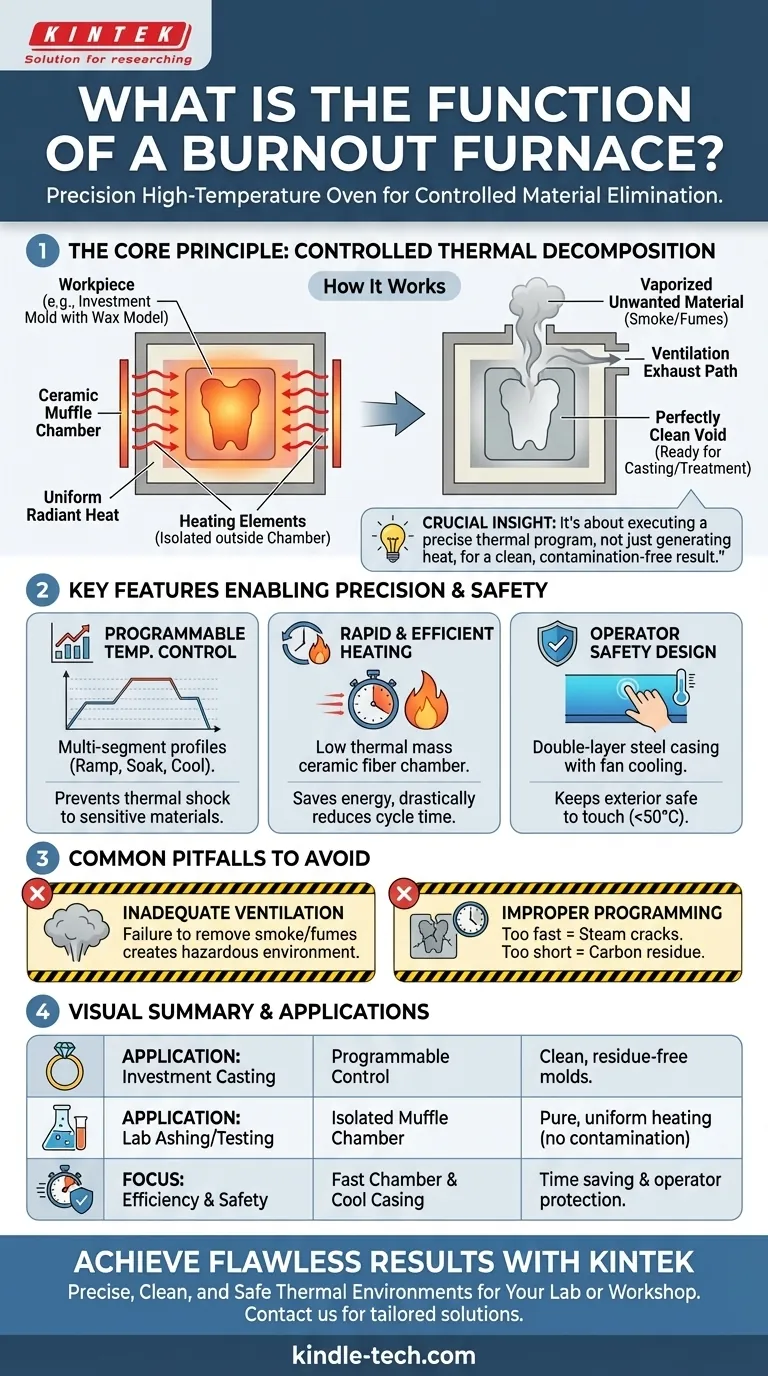

The Core Principle: Controlled Thermal Decomposition

A burnout furnace operates on a simple but critical principle: using carefully managed heat to break down and remove specific materials while leaving the primary object intact and clean. This is accomplished through two key design elements.

Eliminating Unwanted Materials

The term "burnout" refers to the core process. In applications like dental or jewelry casting, a wax model is encased in a plaster-like material called investment. The furnace then executes a slow, precise heating cycle that melts and vaporizes the wax, which exits the mold, leaving a perfectly clean cavity ready for molten metal.

Protecting the Workpiece

Most burnout furnaces are a type of muffle furnace. This means the heating elements are separated from the internal chamber (the "muffle"), typically made of ceramic fiber. This design prevents the workpiece from being exposed to combustion byproducts or direct radiation from the heating coils, ensuring a clean process and preventing contamination.

Ensuring Uniform Heating

The isolated chamber design also eliminates temperature variations. It provides extremely uniform, radiant heat from all directions. This prevents hot spots that could crack a delicate investment mold or cause inconsistent results in a heat-treating process.

Key Features that Enable Precision

The function of a burnout furnace is defined by features designed for control, efficiency, and safety. These are not just specifications; they are the tools that enable repeatable, high-quality results.

Programmable Temperature Control

Modern furnaces feature multi-segment controllers. The ability to program 30 or more segments allows users to create complex heating profiles with specific ramp speeds (how fast the temperature rises), soak times (holding at a specific temperature), and cooling rates. This level of control is vital for preventing thermal shock to sensitive materials.

Rapid and Efficient Heating

The use of a ceramic fiber furnace chamber is a significant feature. This material has a very low thermal mass, meaning it heats up and cools down quickly. This saves energy and drastically reduces the time needed for a complete burnout cycle.

Operator Safety

Handling equipment that reaches over 1000°C requires robust safety measures. A double-layer steel casing with fan cooling is standard. This design actively dissipates heat, ensuring the exterior surface remains below 50°C and safe to the touch, which is critical in any professional lab or workshop.

Common Pitfalls to Avoid

While highly effective, success with a burnout furnace depends on understanding its operational requirements. Overlooking these can lead to failed processes or safety hazards.

Inadequate Ventilation

The "burnout" process generates smoke and fumes as materials like wax or polymers are vaporized. The furnace must be placed in a well-ventilated area, often under a dedicated exhaust hood, to safely remove these byproducts.

Improper Programming

Using an incorrect heating schedule is the most common cause of failure. Ramping the temperature too quickly can cause moisture in an investment mold to turn to steam, cracking or destroying it. Conversely, not holding the temperature long enough can leave behind carbon residue, resulting in a contaminated final product.

Making the Right Choice for Your Goal

Selecting and using a burnout furnace effectively comes down to matching its capabilities to your specific application.

- If your primary focus is investment casting (jewelry, dental): The most critical function is the furnace's ability to execute a slow, precise ramp and soak cycle to eliminate wax cleanly without damaging the mold.

- If your primary focus is laboratory ashing or material testing: The key is the uniform heating and isolated muffle chamber, which guarantee repeatable results free from contamination.

- If your primary focus is operational efficiency and safety: The essential features are the fast-heating ceramic fiber chamber and the cool-touch double-wall casing.

Ultimately, a burnout furnace provides the controlled, clean, and safe thermal environment essential for achieving flawless results in precision processes.

Summary Table:

| Function | Key Feature | Benefit |

|---|---|---|

| Remove Wax/Polymers | Programmable Temperature Control | Clean, residue-free molds for casting |

| Prevent Contamination | Isolated Muffle Chamber | Pure, uniform heating for lab samples |

| Ensure Process Safety | Double-Wall Cool-Touch Casing | Operator protection during high-temperature cycles |

| Improve Efficiency | Low Thermal Mass Ceramic Fiber | Fast heat-up and cool-down, saving time and energy |

Ready to achieve flawless results in your lab or workshop? A KINTEK burnout furnace provides the precise, clean, and safe thermal environment essential for investment casting, ashing, and heat treatment processes. Our expertise in lab equipment ensures you get a solution tailored to your specific needs for maximum efficiency and repeatability. Contact us today to discuss how we can enhance your precision thermal processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the firing temperature of dental porcelain? A Guide to Classes from Ultra-Low to High-Fusing

- What is sintering process in dentistry? Transform Milled 'Chalk' into Durable Dental Restorations

- What is in a dental laboratory? Discover the High-Tech Hub Creating Your Perfect Smile

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- How is zirconia sintered? A Guide to the High-Temperature Transformation Process

- What are some features found in many modern dental ovens? Enhancing Precision Through Digital Integration

- What type of zirconia has better esthetics? Choose High-Translucency 4Y/5Y Zirconia for Superior Beauty

- What types of materials can a Dental Press Furnace process? Versatile Solutions for High-Performance Ceramics