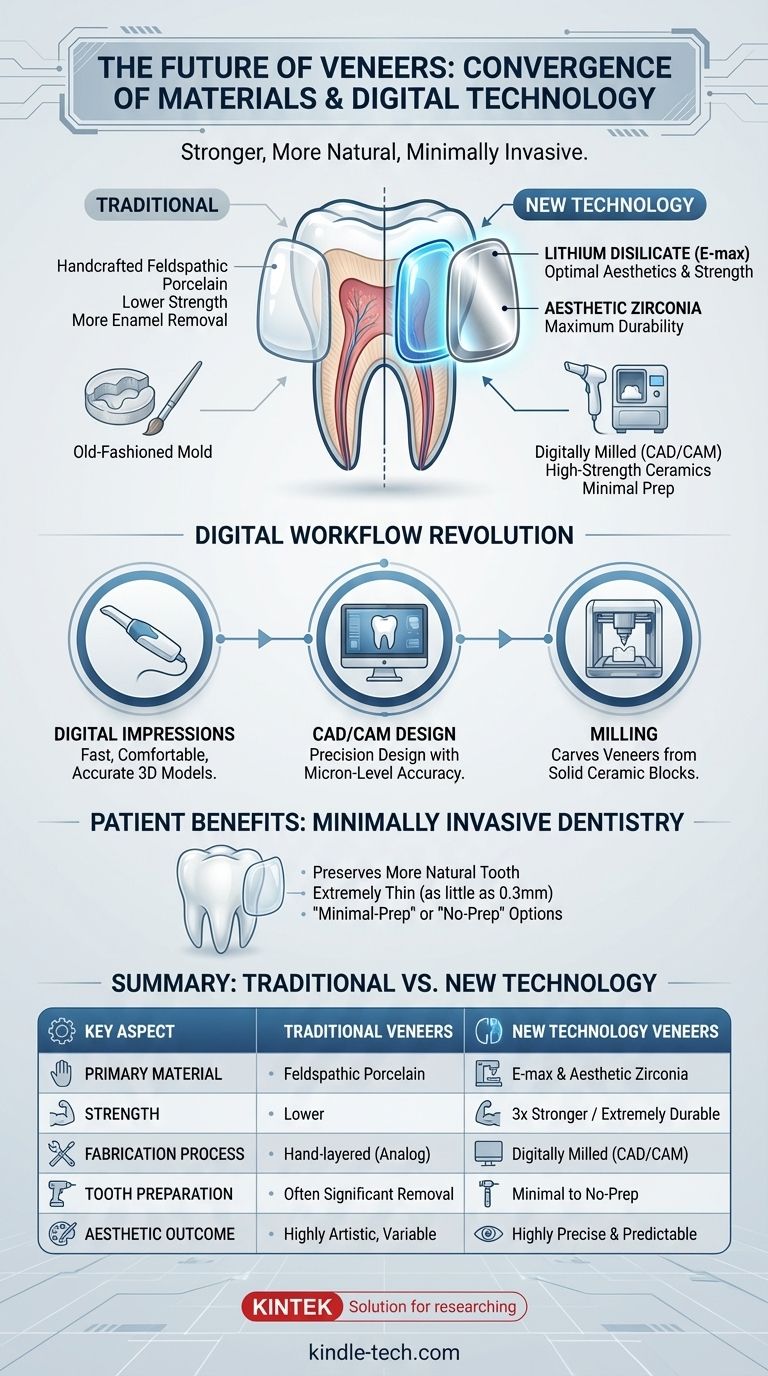

The most significant new technology in veneers is not a single invention, but rather a convergence of advanced materials and digital processes. The biggest advancements are found in ceramic materials like Lithium Disilicate (e.g., E-max) and new forms of Zirconia, which are designed and manufactured using a digital workflow (CAD/CAM). This combination allows for veneers that are stronger, more natural-looking, and require less removal of your natural tooth structure than ever before.

The core shift in veneer technology is from handcrafted, weaker materials to digitally engineered, high-strength ceramics. This allows for a more conservative, precise, and predictable approach to smile enhancement, prioritizing both aesthetics and long-term tooth health.

The Evolution of Veneer Materials

The material used for a veneer is the foundation of its strength, appearance, and longevity. Modern advancements have given dentists a portfolio of options, each with specific strengths.

Feldspathic Porcelain: The Artistic Classic

This is the traditional material, built up by hand in delicate layers by a master ceramist.

While less common now due to lower strength, it can still produce the most beautiful and life-like results in the right hands. It remains a benchmark for high-end aesthetic work where strength is not the primary concern.

Lithium Disilicate (E-max): The Modern Gold Standard

This is arguably the most important material innovation in cosmetic dentistry over the past two decades. It's a type of glass-ceramic known for its brand name, Ivoclar E-max.

Its key advantage is an optimal balance of strength and aesthetics. It has a natural translucency that mimics enamel beautifully and is over three times stronger than older porcelain options.

Zirconia: The Strength Powerhouse

Zirconia is a crystalline ceramic that is exceptionally strong and chip-resistant, often called "ceramic steel."

Traditionally, its strength came at the cost of aesthetics, as it was very opaque and chalky. However, newer formulations like "aesthetic" or "translucent" zirconia have greatly improved its appearance, making it a viable option for veneers, especially in situations requiring maximum durability.

Beyond Materials: The Digital Workflow Revolution

How a veneer is made is just as important as what it's made of. The transition from analog to digital methods has fundamentally changed the precision, speed, and patient experience of getting veneers.

From Putty to Pixels: Digital Impressions

The uncomfortable process of biting into a tray of putty for a dental mold is being replaced by digital intraoral scanners.

These small wands capture thousands of images per second to create a precise 3D model of your teeth. This is faster, more comfortable, and significantly more accurate than physical impressions.

CAD/CAM: Designing and Milling Your Smile

The 3D scan is loaded into Computer-Aided Design (CAD) software, where the dentist or lab technician designs the veneers with micron-level precision.

This digital design is then sent to a Computer-Aided Manufacturing (CAM) milling machine. The mill carves the veneers from a solid block of Lithium Disilicate or Zirconia, ensuring a perfect fit and a robust final product.

The Rise of Minimally Invasive Dentistry

The single greatest patient benefit from these new technologies is the ability to preserve more of your natural tooth.

Because materials like E-max are so strong, they can be milled to be extremely thin (as little as 0.3mm), similar to a contact lens. This allows for "minimal-prep" or even "no-prep" veneers, where little to no healthy enamel needs to be removed.

Understanding the Trade-offs

New technology does not eliminate the need for careful decision-making. The ideal choice depends on a balance of factors, and the skill of the professional is paramount.

Aesthetics vs. Strength

While greatly improved, even the best aesthetic Zirconia typically cannot match the life-like translucency of Lithium Disilicate (E-max).

For front teeth where appearance is the absolute priority, E-max is often the material of choice. For patients who grind their teeth or need veneers on molars, Zirconia may be a more durable solution.

The Skill Factor: Technology is Only a Tool

An intraoral scanner and a milling machine do not guarantee a beautiful result. The final outcome is entirely dependent on the artistry and clinical skill of the dentist and their master lab technician.

Their understanding of facial aesthetics, light dynamics, and tooth morphology is what transforms a block of ceramic into a natural-looking smile.

Cost and Time Implications

The equipment and materials involved in a fully digital workflow represent a significant investment for a dental practice.

While technologies like in-office milling (e.g., CEREC) can enable same-day veneers, the highest-level aesthetic cases are almost always sent to a specialized dental laboratory for custom layering and characterization, which takes more time.

Making the Right Choice for Your Goal

To navigate these new technologies, focus on your primary objective and discuss it with a qualified cosmetic dentist.

- If your primary focus is the most life-like, natural aesthetic: Lithium Disilicate (E-max) is typically the gold standard for blending beauty and strength.

- If your primary focus is maximum durability and chip resistance: Newer forms of aesthetic Zirconia are an excellent choice, especially for back teeth or if you have a heavy bite.

- If your primary focus is preserving your natural tooth structure: Seek a dentist who specializes in minimal-prep veneers, a technique made possible by the strength of modern ceramics.

Ultimately, the most advanced technology is the one that combines the ideal material with the expert hands of a clinical team to achieve your specific goals.

Summary Table:

| Key Aspect | Traditional Veneers | New Technology Veneers |

|---|---|---|

| Primary Material | Feldspathic Porcelain | Lithium Disilicate (E-max), Aesthetic Zirconia |

| Strength | Lower | 3x Stronger (E-max), Extremely Durable (Zirconia) |

| Fabrication Process | Hand-layered (Analog) | Digitally Milled (CAD/CAM) |

| Tooth Preparation | Often requires significant enamel removal | Minimal to no-prep options available |

| Aesthetic Outcome | Highly artistic, variable | Highly precise and predictable |

Ready to explore how modern veneer technology can transform your smile?

At KINTEK, we understand that the success of advanced dental procedures relies on high-quality materials and precise equipment. As a leading provider of laboratory equipment and consumables, we supply the dental industry with the tools needed for cutting-edge CAD/CAM workflows and material processing.

Whether you are a dental lab perfecting the milling of E-max blocks or a clinic implementing digital impressions, KINTEK supports your work with reliable, precision equipment. Let us help you achieve exceptional, long-lasting results for your patients.

Contact our experts today to discuss how KINTEK's solutions can enhance your dental practice or laboratory.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is ceramic powder made of? A Guide to Advanced Ceramic Materials and Their Uses

- Which process parameters were analyzed in the grinding of AlSiTi? Optimize Ceramic Machining Efficiency

- What is the process of sintering ceramics? A Step-by-Step Guide to Dense, High-Strength Parts

- What are the challenges of silicon carbide? Navigating Manufacturing, Reliability, and Integration Hurdles

- Is there an alternative to porcelain crown? Discover Your Best Options for Strength & Aesthetics

- What are the high temperature properties of alumina? Discover Its Stability, Strength, and Limits

- What is another advantage of using ceramics over metals for tooth crowns? Eliminate Temperature Sensitivity and Allergies

- What is the sintering process of advanced ceramics? Transform Powder into High-Performance Components