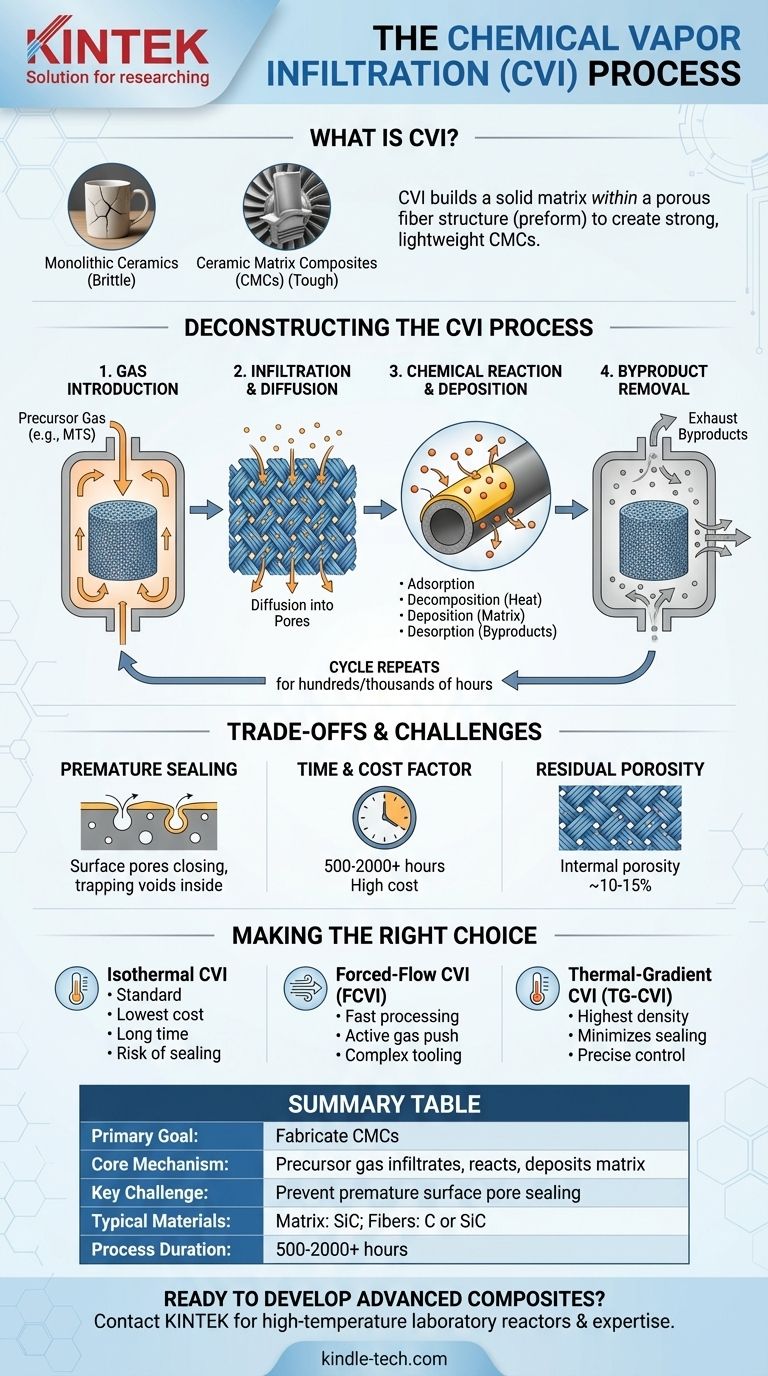

At its core, Chemical Vapor Infiltration (CVI) is a manufacturing process used to fabricate dense, high-performance composite materials. It works by introducing a precursor gas into a porous fibrous structure, called a preform, where the gas undergoes a chemical reaction and deposits a solid material onto the fibers, gradually filling the empty space between them. This densifies the preform, binding the fibers together in a solid matrix to create a strong, lightweight final component.

Chemical Vapor Infiltration is not about coating an external surface; it is about building a solid matrix within a porous fiber structure. This method is the key to creating tough, lightweight, and high-temperature-resistant Ceramic Matrix Composites (CMCs) by slowly depositing material deep inside the component.

The Goal of CVI: Building a Ceramic Matrix Composite (CMC)

To understand the CVI process, you must first understand the material it is designed to create. CVI is the primary method for producing a class of advanced materials known as Ceramic Matrix Composites (CMCs).

From Brittle to Tough

Monolithic ceramics (like a coffee mug) are incredibly resistant to heat and wear, but they are also very brittle and can shatter catastrophically. CMCs solve this problem by embedding strong ceramic fibers within a ceramic matrix.

The fibers act as reinforcement, preventing cracks from propagating through the material and giving the composite a toughness that monolithic ceramics lack.

The Role of the Fiber Preform

The CVI process begins with a "preform." This is a shaped, porous structure made of woven or non-woven fibers, typically carbon (C) or silicon carbide (SiC).

This preform defines the final shape of the component and provides the structural backbone that will be reinforced by the matrix.

The Function of the Matrix

The CVI process fills the empty space within this preform with a solid matrix material, also typically a ceramic like silicon carbide. This matrix locks the fibers in place, transfers loads between them, and protects them from the operational environment.

Deconstructing the CVI Process

The CVI process is fundamentally an application of Chemical Vapor Deposition (CVD) principles, but executed inside a porous body rather than on a simple surface. The steps are sequential and interdependent.

Step 1: Gas Introduction

A volatile precursor gas (or a mix of gases) is introduced into a reactor containing the porous fiber preform. For example, to deposit a silicon carbide matrix, methyltrichlorosilane (MTS) gas is often used.

Step 2: Infiltration and Diffusion

The precursor gas molecules must travel from the reactor environment deep into the intricate network of pores within the preform. This diffusion of gas into the component's interior is a critical and often rate-limiting step.

Step 3: Chemical Reaction and Deposition

Once inside the preform and in contact with the hot fiber surfaces, the precursor gas undergoes a chemical reaction. This is the core CVD mechanism at work:

- Adsorption: Gas molecules land and stick to the surface of the fibers.

- Decomposition: The heat causes the gas molecules to break down or react.

- Deposition: The desired solid material (the matrix) deposits conformally, creating a thin, even layer on the fibers.

- Desorption: Gaseous byproducts from the reaction are released from the surface.

Step 4: Byproduct Removal

The gaseous byproducts must then diffuse out of the preform and be exhausted from the reactor. Efficient removal is crucial to allow fresh precursor gas to continue infiltrating the component. This cycle repeats for hundreds or thousands of hours, slowly building the matrix layer by layer.

Understanding the Trade-offs

While powerful, CVI is a process defined by critical engineering trade-offs. Understanding these is essential for its successful application.

The Challenge of Premature Sealing

The most significant challenge in CVI is preventing the pores at the surface of the preform from closing off before the interior is fully densified.

If the surface seals prematurely, it traps voids within the component, creating a weak part with a dense skin and a porous core. Process parameters like temperature, pressure, and gas flow are carefully controlled to manage this.

The Time and Cost Factor

CVI is an exceptionally slow process. Because deposition rates must be kept low to allow for gas diffusion and prevent premature sealing, densifying a single component can take anywhere from 500 to over 2,000 hours.

This long processing time makes CVI an expensive manufacturing route, generally reserved for high-value, performance-critical applications like aerospace components.

Residual Porosity

Even under ideal conditions, achieving 100% density with CVI is nearly impossible. There is almost always some degree of residual porosity (typically 10-15%) left in the final component, which can influence its mechanical and thermal properties.

Making the Right Choice for Your Application

Different variants of the CVI process have been developed to manage the inherent trade-offs between speed, cost, and final part quality.

- If your primary focus is lowest cost and process simplicity: Isothermal CVI (where the entire component is at one temperature) is the standard, but you must accept very long processing times and manage the risk of surface sealing.

- If your primary focus is processing speed and uniform density: Forced-Flow CVI (FCVI), which actively pushes gases through the preform, significantly reduces processing time but requires more complex and expensive tooling.

- If your primary focus is achieving the highest possible density and minimizing surface sealing: Thermal-Gradient CVI (TG-CVI), which heats the preform from the inside out to force deposition to begin in the core, offers the best quality but demands precise thermal control.

Understanding these CVI fundamentals empowers you to select and optimize the manufacturing path for creating robust, high-performance composite materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Fabricate Ceramic Matrix Composites (CMCs) from a porous fiber preform. |

| Core Mechanism | Precursor gas infiltrates a preform, reacts on hot fiber surfaces, and deposits a solid matrix material. |

| Key Challenge | Preventing premature surface pore sealing to ensure complete internal densification. |

| Typical Materials | Matrix: Silicon Carbide (SiC). Fibers: Carbon (C) or Silicon Carbide (SiC). |

| Process Duration | Slow process, typically ranging from 500 to over 2,000 hours. |

Ready to Develop Advanced Composite Materials?

The intricate CVI process demands precision equipment and expert knowledge. KINTEK specializes in high-temperature laboratory reactors and systems essential for advanced materials development, including CMC research and production. Our solutions help you achieve the precise temperature and gas control critical for successful CVI.

Contact us today using the form below to discuss how our expertise and equipment can accelerate your composite materials projects. #ContactForm

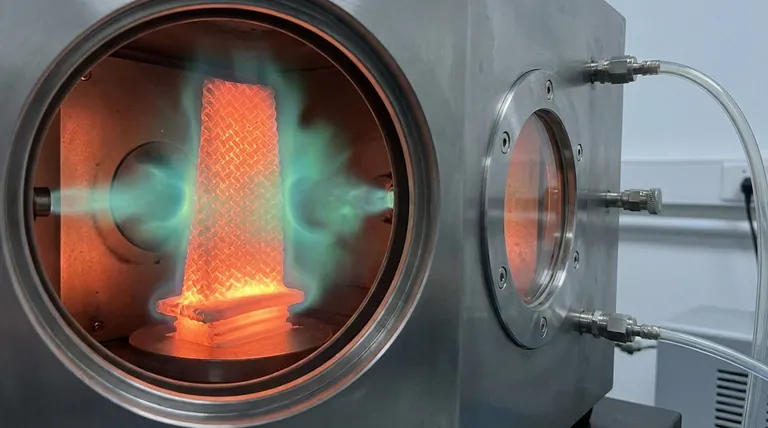

Visual Guide

Related Products

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does a three-zone high-temperature split tube furnace ensure data accuracy in creep experiments? Achieve Thermal Precision

- Why is a controlled atmosphere tube furnace required for HPS catalysts? Ensure Optimal Metal Site Activation

- Why is high-temperature hydrogen reduction in a tube furnace necessary before carbon nanofiber growth? Catalyst Activation Explained

- How is a high-temperature tube furnace utilized in the synthesis of SPAN? Optimize Your Li-S Battery Research Today

- How do vertical split tube furnaces and preheaters facilitate SCWO? Achieve Optimal Supercritical Water Oxidation