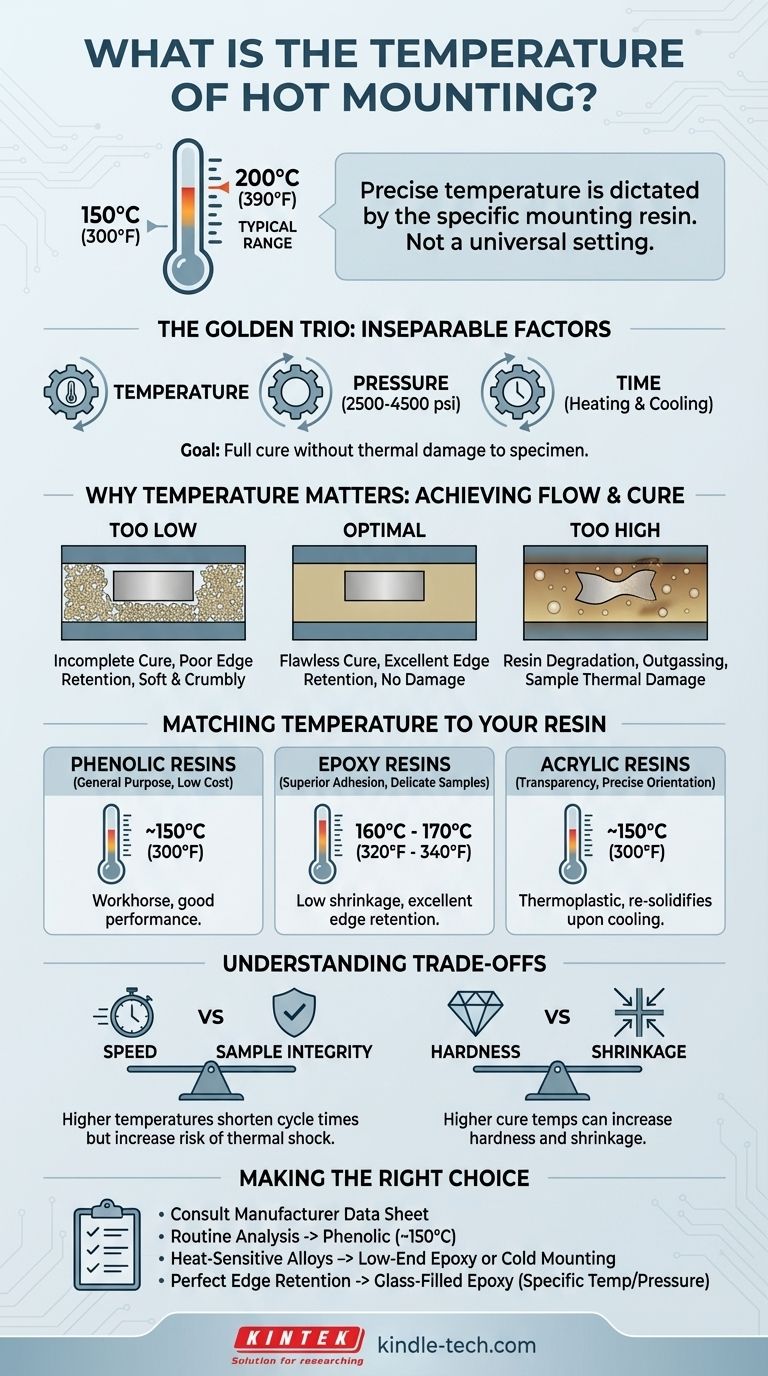

In hot compression mounting, the process temperature typically falls within the range of 150°C to 200°C (300°F to 390°F). However, this is not a universal setting; the precise temperature is dictated by the specific type of mounting resin compound you are using, as each has its own requirements for optimal melting, flow, and curing.

The central challenge of hot mounting isn't just reaching a target temperature, but understanding that temperature, pressure, and time form an inseparable trio. The goal is to fully cure the mounting compound without inducing thermal damage or altering the delicate microstructure of the specimen you intend to analyze.

Why Temperature Is More Than Just a Number

Hot mounting, or compression mounting, is a foundational step in metallographic sample preparation. Its purpose is to encapsulate a specimen in a standardized, durable polymer puck for subsequent grinding and polishing. Temperature is the primary catalyst in this process, and its effects are profound.

Achieving Resin Flow and Cure

The initial application of heat melts the granular mounting compound, allowing it to transition into a liquid state. This is crucial for the resin to flow around the specimen and fill the mold cavity completely. For thermosetting resins like phenolics and epoxies, temperature then initiates a chemical cross-linking reaction, or curing, which permanently hardens the material into a solid, infusible puck.

The Risk of an Incomplete Cure

Using a temperature that is too low for the specified resin is a common failure point. The compound may not melt fully or the curing reaction will be incomplete. This results in a soft, crumbly mount that provides poor edge retention and will likely be destroyed during grinding.

The Danger of Overheating

Conversely, excessive temperature can be catastrophic to your analysis. It can degrade the mounting compound itself, causing discoloration or outgassing that leads to porosity. More critically, it can alter the very sample you are trying to study by inducing phase changes, tempering effects, or other forms of thermal damage, invalidating any subsequent microstructural examination.

Matching Temperature to Your Mounting Compound

The ideal temperature is determined entirely by the material science of the polymer resin you choose. Each type is engineered to perform within a specific operational window.

Phenolic Resins (The Workhorse)

Phenolic compounds (such as Bakelite) are the most common general-purpose mounting material due to their low cost and good performance. They typically require a molding temperature of approximately 150°C (300°F).

Epoxy Resins (For Superior Adhesion)

Epoxy-based thermosetting compounds are chosen for their excellent adhesion, low shrinkage, and superb edge retention, making them ideal for delicate, coated, or porous samples. They often require slightly higher temperatures, typically in the range of 160°C to 170°C (320°F to 340°F).

Acrylic Resins (For Clarity)

Acrylics are thermoplastic resins, meaning they soften when heated and re-solidify upon cooling without a chemical curing reaction. Their primary benefit is transparency, allowing for precise orientation of the specimen within the mold. Their processing temperature is usually around 150°C (300°F).

Understanding the Trade-offs

Selecting a mounting temperature is an exercise in balancing competing factors. There is no single "best" setting, only the optimal one for a specific sample and analytical goal.

Speed vs. Sample Integrity

While higher temperatures can shorten cycle times, they dramatically increase the risk of thermal shock to the specimen, especially during the cooling phase. This can introduce cracks or artifacts that were not present in the original material. For sensitive materials, a slower cycle at the lowest effective temperature is always the safer approach.

Hardness vs. Shrinkage

The final hardness of the mount is critical; it should be similar to the specimen to ensure a flat, even polish. Resins with higher hardness requirements might need higher curing temperatures. However, this can sometimes correlate with greater shrinkage as the mount cools, which can pull the resin away from the specimen and create gaps at the interface.

The Role of Pressure and Time

Temperature does not work in isolation. Pressure (typically 2500-4500 psi) is required to compact the resin powder and ensure it flows into every crevice, eliminating voids. Heating and cooling times are equally critical. A proper holding time at peak temperature ensures a complete cure, while a controlled cooling cycle prevents internal stresses and cracking.

Making the Right Choice for Your Goal

Always begin by consulting the manufacturer's data sheet for your specific mounting compound. From there, tailor the parameters to your objective.

- If your primary focus is routine, high-volume analysis of robust materials: A general-purpose phenolic resin at its recommended temperature (~150°C) provides a reliable and cost-effective solution.

- If your primary focus is preserving the true microstructure of a heat-sensitive alloy: Consider an epoxy-based compound at the lowest end of its effective temperature range, or investigate cold mounting as a superior alternative.

- If your primary focus is failure analysis requiring perfect edge retention: Use a glass-filled epoxy or diallyl phthalate resin, following its specific temperature and pressure guidelines meticulously to minimize shrinkage.

Ultimately, mastering hot mounting comes from understanding that temperature is not just a setting, but a precise tool to achieve a flawless foundation for your analysis.

Summary Table:

| Resin Type | Typical Temperature Range | Key Characteristics |

|---|---|---|

| Phenolic Resins | ~150°C (300°F) | Low cost, good for general-purpose use |

| Epoxy Resins | 160°C - 170°C (320°F - 340°F) | Superior adhesion, excellent for delicate samples |

| Acrylic Resins | ~150°C (300°F) | Transparency, ideal for precise specimen orientation |

Achieve flawless sample preparation with KINTEK's precision hot mounting presses. Our laboratory equipment is engineered to deliver the exact temperature, pressure, and cycle control required for perfect specimen encapsulation. Whether you're working with robust materials or delicate, heat-sensitive alloys, KINTEK provides the reliable performance you need for accurate microstructural analysis. Don't let improper mounting compromise your results—contact our experts today to find the ideal solution for your lab's specific requirements.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What are the properties and handling precautions for alumina powder as a polishing material? Achieve a Flawless Finish with Precision

- What is the purpose of alumina polishing powder in GCE pretreatment? Master Surface Prep for Electrochemistry

- What are the characteristics and maintenance instructions for metallographic polishing suede? Ensure a Perfect Finish

- How do alumina and cerium oxide polishing powders aid high-entropy alloy prep? Achieve Mirror-Like Precision

- How do laboratory mounting systems or hydraulic presses assist in oxide layer prep? Ensure Perfect Sample Integrity

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- What is the purpose and usage guidelines for a general polishing wiping cloth? Ensure a Pristine, Scratch-Free Finish

- What is the process of mounting in metallurgy? A Guide to Perfect Specimen Preparation