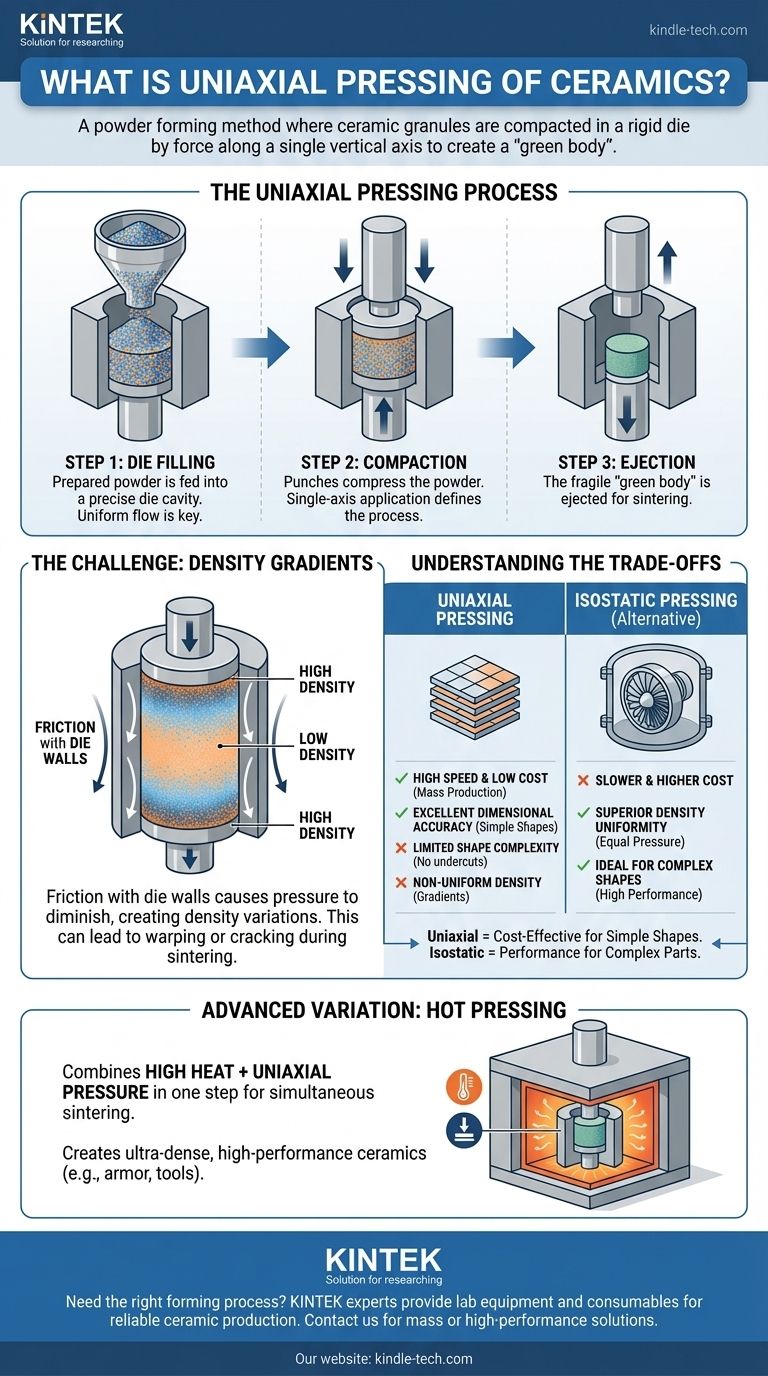

At its core, uniaxial pressing of ceramics is a powder forming method where granulated ceramic powder is compacted within a rigid die by applying force along a single vertical axis. This process uses punches, typically moving from the top and/or bottom, to press the powder into a coherent, geometrically defined shape known as a "green body" before it undergoes final firing (sintering).

Uniaxial pressing is the go-to method for high-volume, cost-effective production of simple ceramic shapes. Its primary challenge, however, is that applying pressure from only one direction creates density variations within the part, a critical factor that must be managed for high-performance applications.

How Uniaxial Pressing Works

Uniaxial pressing is a mechanically straightforward and highly automatable process, which is the source of its widespread industrial use. The entire cycle can be broken down into three fundamental steps.

Step 1: Die Filling

The process begins with a precise volume of prepared ceramic powder or granules being fed into a hardened steel or carbide die cavity. The consistency and flowability of this powder are critical for ensuring the die fills uniformly.

Step 2: Compaction

One or more punches move vertically to compress the powder inside the die. In the simplest setup, a single top punch moves down. More advanced presses use both an upper and a lower punch, which move toward each other to improve density uniformity. The term uniaxial refers to this single axis of pressure application.

Step 3: Ejection

Once the desired compaction pressure is reached, the top punch retracts. The newly formed part, now a fragile "green body," is pushed out of the die cavity by the lower punch. This green body has enough strength to be handled but requires a subsequent high-temperature sintering step to achieve its final density and strength.

The Critical Challenge: Density Gradients

The defining limitation of uniaxial pressing is the non-uniform density it creates. This phenomenon is a direct consequence of the physics of the process.

The Role of Friction

As the punches compress the powder, friction occurs between the ceramic granules and the rigid die walls. This friction opposes the applied pressure, causing the force to diminish as it travels through the powder column.

The Inevitable Result

The powder closest to the moving punches is compacted to a higher density, while the powder in the middle of the part (and furthest from the punch faces) receives less pressure and remains at a lower density. This creates a predictable density gradient within the green body.

Impact on Final Properties

These density variations are problematic because they lead to differential shrinkage during the final sintering stage. Less dense regions shrink more than high-density regions, which can cause warping, cracking, or internal stresses, ultimately compromising the mechanical integrity of the final ceramic component.

Understanding the Trade-offs

Choosing a forming method requires understanding its strengths and weaknesses, especially when compared to its primary alternative, isostatic pressing.

Advantage: Speed and Cost

Uniaxial pressing is extremely fast, with cycle times often measured in seconds. This makes it exceptionally well-suited for the mass production of parts like ceramic tiles, substrates, and simple insulators, driving down per-unit costs.

Advantage: Dimensional Accuracy

The use of a rigid, precisely machined die provides excellent control over the radial dimensions (the width and length) of the part. This results in high repeatability from part to part.

Limitation: Shape Complexity

The process is limited to shapes with a constant cross-section that can be easily ejected from the die. Features like undercuts or transverse holes are impossible to produce directly.

Limitation: Density Uniformity

This is the key weakness. Isostatic pressing, where pressure is applied equally from all directions via a fluid medium, produces a vastly more uniform green body. This makes it the preferred method for complex, high-performance components where consistent material properties are non-negotiable.

Advanced Variation: Hot Pressing

A specialized version of this technique, known as hot pressing, combines uniaxial pressure with high temperature in a single step.

Combining Heat and Pressure

In hot pressing, the die and powder assembly are heated in a controlled atmosphere furnace. Pressure is applied uniaxially, just as in the cold process, but at temperatures high enough to cause sintering.

The Sintering Advantage

This simultaneous action of heat and pressure dramatically aids the densification process. It allows for the production of ceramic parts with near-full density and a very fine-grained microstructure, which is often difficult to achieve with conventional sintering.

High-Performance Applications

Hot pressing is used to create elite materials, such as boron carbide (B₄C) armor, silicon nitride (Si₃N₄) cutting tools, and other advanced technical ceramics that are inherently difficult to densify.

Making the Right Choice for Your Application

Selecting the correct forming process is a critical decision that directly impacts component quality, performance, and cost.

- If your primary focus is mass production and cost-efficiency for simple shapes: Uniaxial pressing is the dominant, most economical choice for items like electronic substrates, capacitors, and tiles.

- If your primary focus is maximum density and mechanical reliability for complex shapes: Isostatic pressing is the superior method, essential for parts like medical implants or turbocharger rotors.

- If your primary focus is fabricating ultra-high-density parts from difficult-to-sinter materials: Hot uniaxial pressing is the necessary specialized process for a range of defense and industrial cutting applications.

Ultimately, selecting the right pressing method requires balancing the geometric complexity of your part with its required performance and production cost.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Compacting powder in a die with force along a single vertical axis. |

| Primary Use | High-volume production of simple shapes (tiles, substrates, insulators). |

| Key Advantage | High speed, low cost, and excellent dimensional accuracy for simple shapes. |

| Key Limitation | Density gradients within the part due to friction with die walls. |

| Advanced Variation | Hot pressing combines pressure and heat for ultra-dense, high-performance ceramics. |

Need to choose the right ceramic forming process for your lab's specific application? The experts at KINTEK can help. We specialize in lab equipment and consumables, providing the solutions you need for efficient and reliable ceramic production. Whether you're working on mass-produced components or high-performance materials, we have the expertise to support your project. Contact us today to discuss your requirements and optimize your process!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- What is the role of a laboratory hydraulic press in Al-doped LLZO pre-treatment? Ensure Dense Electrolyte Formation.

- What are the functions of a laboratory hydraulic press in cathode research? Optimize High-Nickel Electrode Preparation

- What is the factor of safety for a hydraulic press? It's a System, Not a Single Number

- What happens when hydraulic oil gets too hot? Prevent Costly System Failure

- How can I make my hydraulic system more efficient? Slash Energy Costs and Reduce Heat Generation

- What can destroy a hydraulic press? Avoid These Common & Costly Mistakes

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock

- Why is a uniaxial hydraulic press used before testing Li2O–LiI–MoO3? Achieve Dense Pellets for Accurate Conductivity