The most common materials used for heating elements are specialized metal alloys like Nichrome (nickel-chromium) and Kanthal (iron-chromium-aluminum), as well as ceramics like Silicon Carbide (SiC) for higher-temperature industrial applications. The choice of material depends entirely on the required operating temperature, cost, and environment.

The ideal material for a heating element is not a good conductor, but rather a poor one with high electrical resistance. This resistance converts electrical energy into heat, and the material must be robust enough to withstand that heat without melting or degrading.

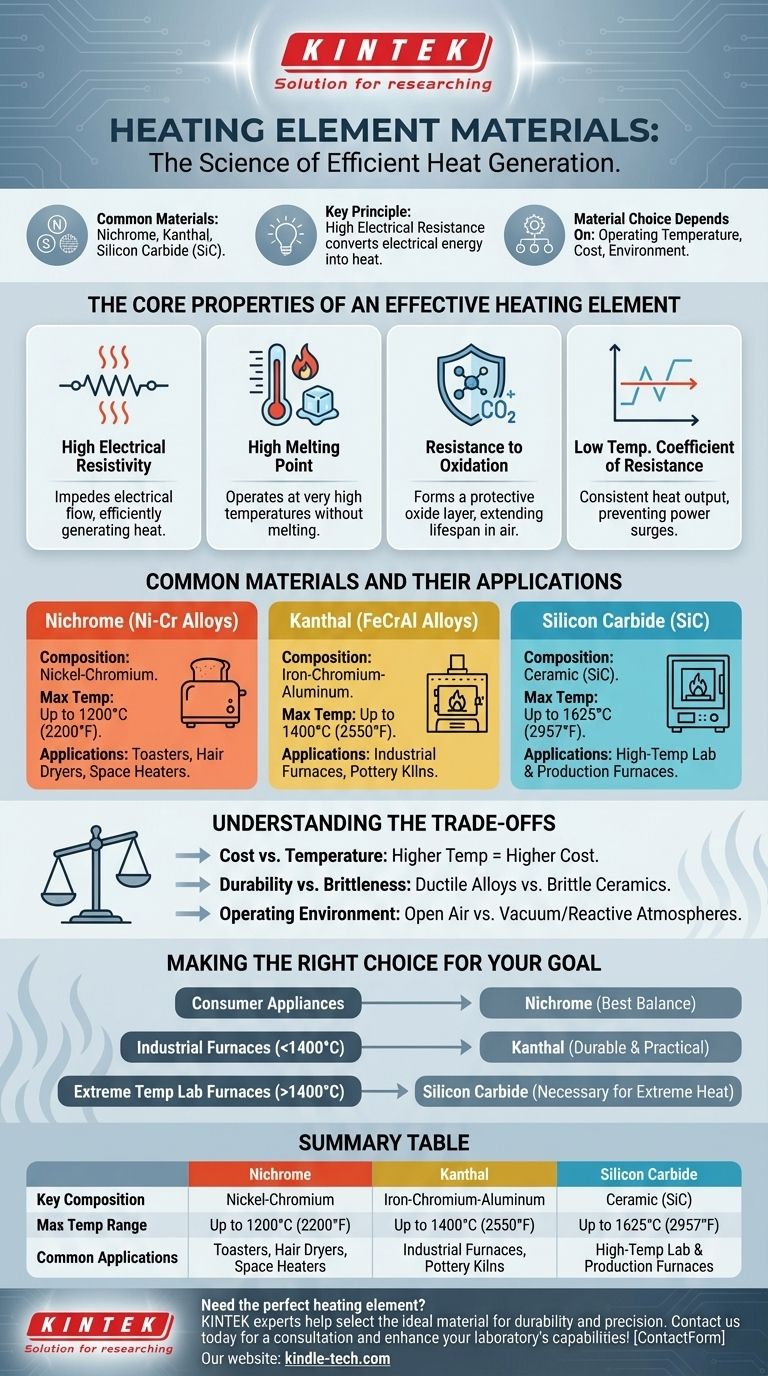

The Core Properties of an Effective Heating Element

To understand why specific materials are chosen, we must first look at the essential properties they need to possess. The goal is to generate heat reliably and for a long time.

High Electrical Resistivity

A heating element works by impeding the flow of electricity. According to Joule's law of heating, the heat produced is proportional to the material's electrical resistance.

A high resistivity means more heat is generated from the electrical current passing through it, making the process efficient.

High Melting Point

This is a fundamental requirement. The material must operate at very high temperatures without melting or becoming soft.

A high melting point ensures the element maintains its structural integrity and function even when glowing red-hot.

Resistance to Oxidation

When heated in the presence of air, most metals will rapidly oxidize (corrode) and fail.

Effective heating element alloys like Nichrome and Kanthal form a thin, durable, and adherent outer layer of oxide. This layer protects the underlying material from further oxygen attack, dramatically extending the element's lifespan.

Low Temperature Coefficient of Resistance

This property ensures the element's resistance remains relatively stable as its temperature changes.

A low coefficient means the heat output is predictable and consistent, preventing sudden power surges as the element heats from cold to its operating temperature.

Common Materials and Their Applications

While many materials fit these criteria, a few have become industry standards for specific temperature ranges and uses.

Nichrome (Nickel-Chromium Alloys)

Nichrome is the workhorse for most consumer appliances, such as toasters, hair dryers, and space heaters.

It offers an excellent balance of high resistance, good oxidation resistance, and cost-effectiveness for temperatures typically up to 1200°C (2200°F).

Kanthal (FeCrAl Alloys)

Kanthal alloys are a common alternative to Nichrome, particularly in high-temperature industrial applications like pottery kilns and furnaces.

They can often operate at higher temperatures than Nichrome and form a very stable aluminum oxide protective layer.

Silicon Carbide (SiC)

Silicon Carbide is a ceramic material used when temperatures exceed the limits of metallic alloys, often in industrial furnaces and kilns.

These elements are more brittle than metal but can function reliably at temperatures up to 1625°C (2957°F).

Understanding the Trade-offs

Choosing a heating element material is rarely about finding the "best" one, but rather the most appropriate one for the task.

Cost vs. Temperature

As the required operating temperature increases, so does the cost of the material. Nichrome is relatively inexpensive, while materials for the most extreme temperatures, like Molybdenum Disilicide, are significantly more costly.

Durability vs. Brittleness

Metallic alloys like Nichrome are ductile and can be easily formed into coils, making them resistant to physical shock. Ceramic elements like Silicon Carbide offer superior heat performance but are brittle and must be handled with care.

Operating Environment

The environment is critical. While Nichrome and Kanthal excel in open air due to their protective oxide layers, they may not be suitable for vacuum or certain chemically reactive atmospheres where other materials would be required.

Making the Right Choice for Your Goal

Your application will dictate the correct material.

- If your primary focus is consumer appliances or general heating: Nichrome is the industry standard, offering the best balance of performance and cost.

- If your primary focus is industrial furnaces up to 1400°C (2550°F): Kanthal (FeCrAl) alloys are often the most practical and durable choice.

- If your primary focus is very high-temperature lab or production furnaces: Ceramic elements like Silicon Carbide are necessary to withstand extreme heat.

Ultimately, selecting the right heating element material is a deliberate decision based on the required temperature, operating environment, and budget.

Summary Table:

| Material | Key Composition | Max Temp Range | Common Applications |

|---|---|---|---|

| Nichrome | Nickel-Chromium | Up to 1200°C (2200°F) | Toasters, Hair Dryers, Space Heaters |

| Kanthal | Iron-Chromium-Aluminum | Up to 1400°C (2550°F) | Industrial Furnaces, Pottery Kilns |

| Silicon Carbide | Ceramic (SiC) | Up to 1625°C (2957°F) | High-Temp Lab & Production Furnaces |

Need the perfect heating element for your lab furnace or industrial process?

KINTEK specializes in high-performance lab equipment and consumables. Our experts will help you select the ideal heating element material—whether Nichrome, Kanthal, or Silicon Carbide—to ensure durability, efficiency, and precise temperature control for your specific application.

Contact our team today for a consultation and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Double Plate Heating Press Mold for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is SiC elements? The Ultimate High-Temperature Heating Solution