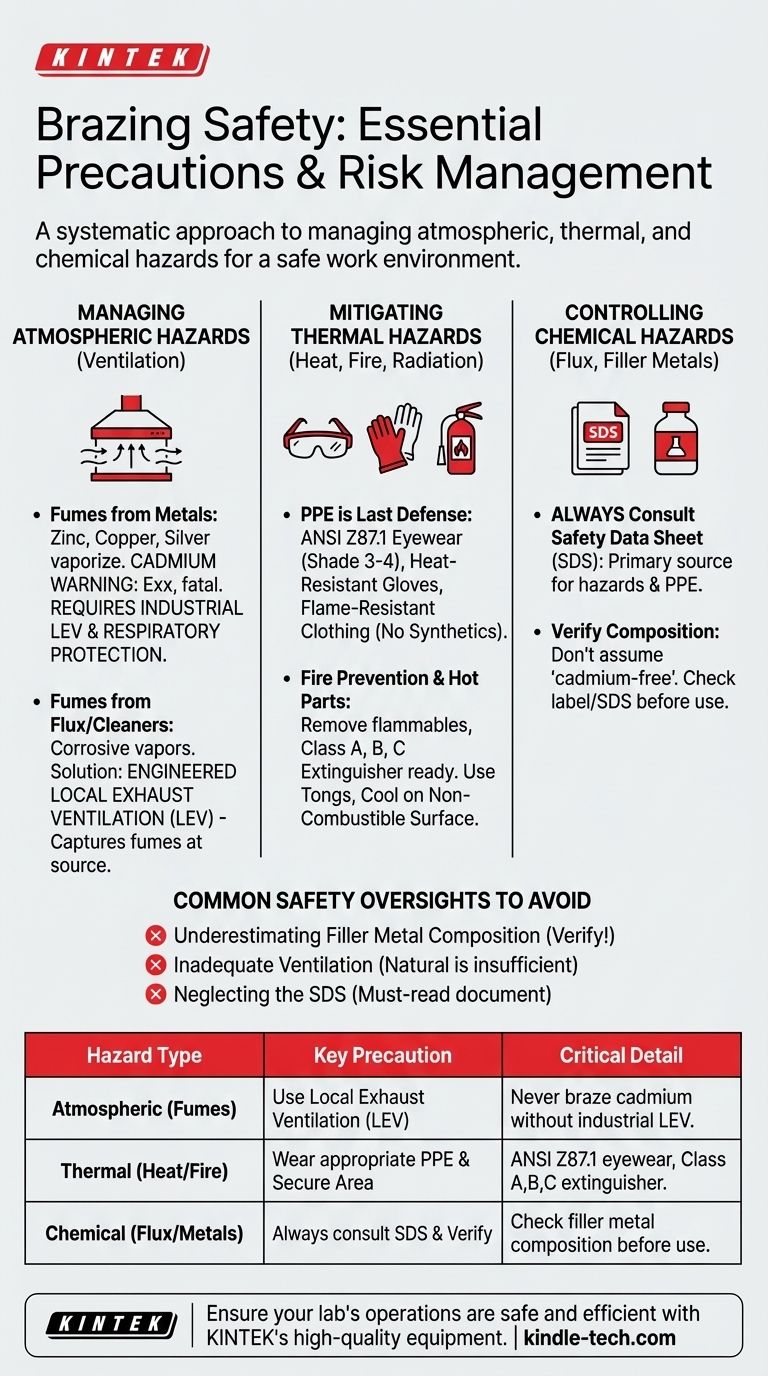

When performing any brazing operation, your primary precautions must address atmospheric, thermal, and chemical hazards. This involves ensuring robust ventilation to remove harmful fumes, utilizing appropriate Personal Protective Equipment (PPE) to guard against extreme heat and radiation, and implementing strict fire prevention measures. Safe handling of fluxes, cleaners, and filler metals, guided by their Safety Data Sheets (SDS), is equally critical to prevent chemical exposure and ensure a safe work environment.

Brazing safety transcends a simple checklist; it is a systematic approach to managing risk. The core challenge is not just the visible flame but the invisible hazards—toxic fumes, chemical agents, and latent heat—which requires a conscious strategy for ventilation, personal protection, and workspace control.

Managing Atmospheric Hazards: The Importance of Ventilation

Controlling the air you breathe is the most critical precaution in brazing. The high temperatures involved can vaporize materials, creating fumes that range from irritating to highly toxic.

Fumes from Filler Metals and Base Metals

Many brazing filler metals contain elements like zinc, copper, or silver. When overheated, these can produce metal fumes that may cause metal fume fever, a temporary but debilitating flu-like illness.

The greatest risk comes from filler metals containing cadmium. Cadmium fumes are extremely toxic, have poor warning properties (they are not irritating), and can cause severe lung damage or death, even from short-term overexposure. Never braze with cadmium-bearing alloys unless you have industrial-grade local exhaust ventilation and respiratory protection.

Fumes from Flux and Cleaners

Brazing fluxes and chemical cleaning agents can also release hazardous fumes when heated. These vapors can be corrosive and irritate the eyes, nose, throat, and respiratory system.

The Solution: Engineered Ventilation

Natural ventilation, such as an open window, is insufficient for most brazing tasks. Local Exhaust Ventilation (LEV), which uses a hood to capture fumes at the source and vent them outside, is the standard for safe operation.

Mitigating Thermal Hazards: Heat, Fire, and Radiation

Brazing generates intense, localized heat that presents significant fire and burn risks.

Protecting Personnel with PPE

Your Personal Protective Equipment (PPE) is your last line of defense.

- Eye Protection: Wear safety glasses with a minimum shade rating of 3 or 4 to protect against infrared radiation. Always use eyewear that meets the ANSI Z87.1 standard.

- Hand Protection: Dry, insulated, and heat-resistant gloves are mandatory for handling parts and equipment.

- Body Protection: Wear flame-resistant clothing, such as leather or treated cotton, to protect against sparks and heat. Avoid synthetic fabrics like polyester, which can melt and cause severe burns.

Securing the Work Area

Before lighting a torch, prepare your environment. Remove all flammable materials—including paper, rags, wood, and flammable liquids—from the vicinity. A fire extinguisher rated for Class A, B, and C fires should be within easy reach.

Safe Handling of Hot Parts

The workpiece will remain dangerously hot long after the flame is removed. Always use tongs or pliers to handle recently brazed components and place them on a fire-brick or other non-combustible surface to cool.

Common Safety Oversights and How to Avoid Them

Even experienced operators can make mistakes. Being aware of common pitfalls is key to maintaining a safe environment.

Underestimating Filler Metal Composition

The single most dangerous oversight is failing to identify the composition of your filler metal. Assuming an alloy is "cadmium-free" is not enough; you must verify it by checking the product label or Safety Data Sheet (SDS). If you are unsure, assume it contains hazardous materials and use maximum protection.

Inadequate Ventilation

A frequent mistake is believing a large room or an open garage door provides sufficient ventilation. Metal fumes are often heavier than air and can accumulate in your breathing zone. Only a dedicated LEV system can reliably capture and remove these hazards at their source.

Neglecting the Safety Data Sheet (SDS)

Every chemical product, including flux and filler metal, is supplied with an SDS. This document is not optional reading; it is your primary source of information on specific hazards, required PPE, and emergency procedures. Always read it before using a new material.

Making the Right Choice for Your Goal

Your approach to safety should be deliberate and systematic. Use this framework to prepare for your next brazing operation.

- If your primary focus is personal health: Prioritize ventilation above all else, and always read the SDS to understand the specific fume hazards of your materials.

- If your primary focus is burn and fire prevention: Conduct a thorough sweep of your work area for combustibles and ensure your PPE, especially eye and hand protection, is in good condition.

- If your primary focus is creating a repeatable safety process: Develop a pre-brazing checklist that includes verifying your ventilation, confirming you have the correct fire extinguisher, and reviewing the SDS for all consumables.

A proactive and informed approach to safety is the mark of a true professional and ensures a successful outcome.

Summary Table:

| Hazard Type | Key Precaution | Critical Detail |

|---|---|---|

| Atmospheric (Fumes) | Use Local Exhaust Ventilation (LEV) | Never braze cadmium alloys without industrial-grade LEV and respiratory protection. |

| Thermal (Heat/Fire) | Wear appropriate PPE (ANSI Z87.1 eyewear, heat-resistant gloves) | Remove all flammable materials and have a Class A, B, C fire extinguisher ready. |

| Chemical (Flux/Filler Metals) | Always consult the Safety Data Sheet (SDS) | Verify filler metal composition (e.g., cadmium content) before use to avoid toxic exposure. |

Ensure your lab's brazing operations are safe and efficient. KINTEK specializes in providing high-quality lab equipment and consumables for all your laboratory needs. Our experts can help you select the right safety gear and materials for your specific brazing applications. Contact us today to discuss how we can support your lab's safety and productivity!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How do you test a metal to determine its quality? Verify Mechanical & Chemical Properties for Your Application

- What is furnace soldering? A High-Volume Process for Joining Components

- What materials are used in the forging process? Choose the Right Metal for Strength & Performance

- What are the disadvantages of graphene coating? High Cost, Difficult Application & Misleading Marketing

- What is the recommended temperature for storing proteins? Ensure Long-Term Stability and Activity

- What is e-beam used for? A High-Speed, Non-Thermal Solution for Sterilization & Material Enhancement

- What are the key applications of inert gases? Discover Their Role in Industry and Preservation

- What is the sintering temperature of polymers? Find Your Material's Perfect Sintering Window