High frequency is used in induction furnaces to achieve precise and shallow heating in a conductive material. This is necessary for applications like surface hardening, where only the outer layer of a part needs to be altered, or for efficiently heating very small or thin components. The higher the frequency of the alternating current in the induction coil, the more the resulting heat is concentrated near the surface of the workpiece.

The choice of operating frequency is the most critical parameter in induction heating design. It is a direct trade-off: higher frequencies concentrate energy near the surface for rapid, localized heating, while lower frequencies penetrate deeper for uniform, bulk heating. Understanding this principle is key to controlling the metallurgical outcome.

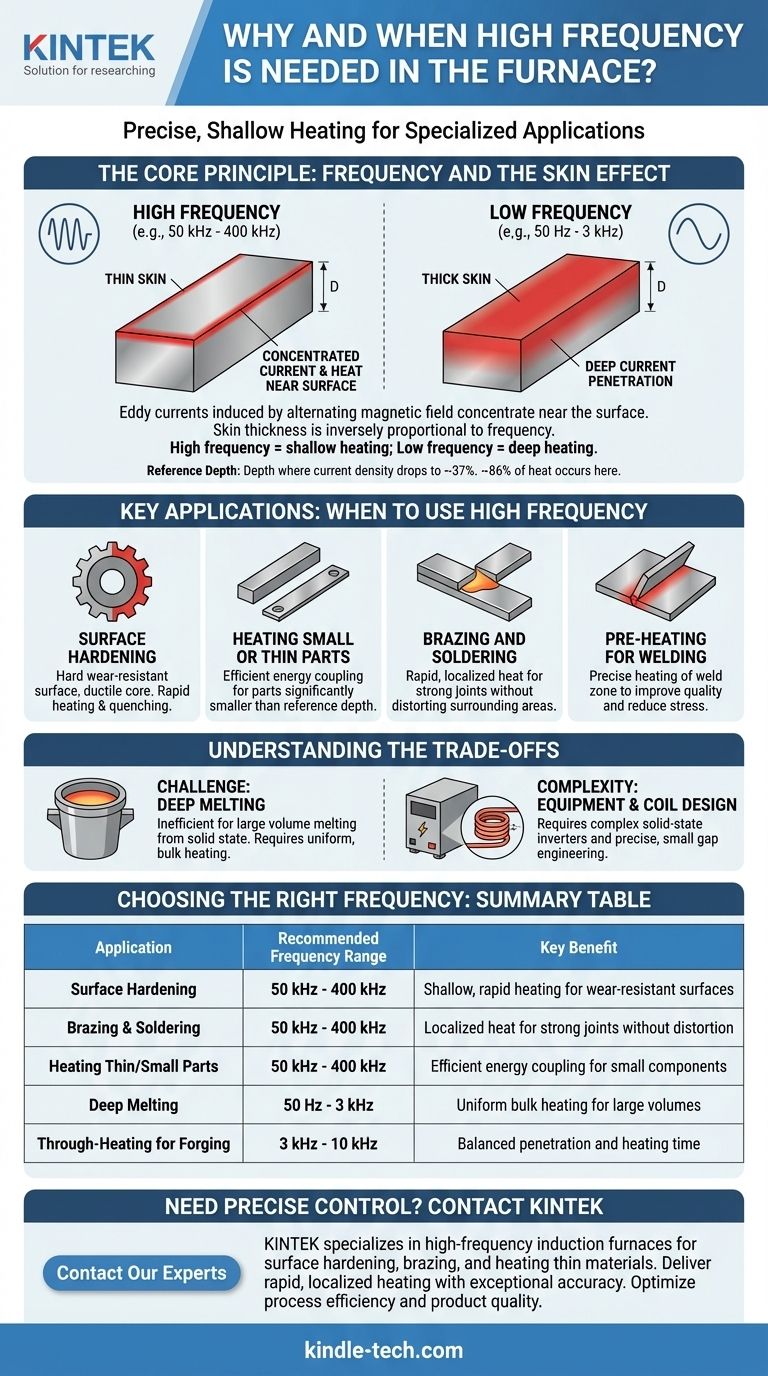

The Core Principle: Frequency and the Skin Effect

To understand when to use high frequency, you must first grasp the fundamental physics at play. The decision is governed by a phenomenon known as the "skin effect."

What is the Skin Effect?

The skin effect is the tendency of an alternating electric current (AC) to become distributed within a conductor so that the current density is largest near the surface. The current effectively flows in the outer "skin" of the material.

In an induction furnace, an alternating magnetic field from the coil induces these currents (called eddy currents) within the workpiece. The resistance of the material to the flow of these currents generates precise, contactless heat.

How Frequency Controls Heating Depth

The thickness of this "skin" is inversely proportional to the frequency of the alternating current.

- High Frequency (e.g., 50 kHz to 400 kHz) creates a very thin skin, concentrating the current and the resulting heat in a shallow layer near the surface.

- Low Frequency (e.g., 50 Hz to 3 kHz) creates a much thicker skin, allowing the current and heat to penetrate deep into the material's core.

Think of it like skipping a stone on water. A fast, high-frequency spin keeps the stone right at the surface. A slow, low-frequency toss causes it to sink deep.

The Concept of Reference Depth

Engineers use the term reference depth (or penetration depth) to quantify this. It is the depth at which the induced current density drops to about 37% of its value at the surface. Roughly 86% of the total heat generated by the induced currents will occur within this reference depth.

When to Use High Frequency: Key Applications

The shallow heating characteristic of high frequencies makes it the ideal choice for several specific industrial processes.

Surface Hardening and Heat Treating

This is the most common application. For parts like gears, bearings, or shafts, you need an extremely hard, wear-resistant surface while maintaining a softer, more ductile core to absorb shock. High frequency heats only the surface to the required transformation temperature, which is then rapidly cooled (quenched), achieving a hardened case without affecting the core's properties.

Heating Small or Thin Parts

When heating small-diameter bars or thin strips, the reference depth must be significantly smaller than the part's radius. If you use a low frequency, the magnetic field can pass straight through the part with little resistance, resulting in very inefficient heating. High frequency ensures the energy is effectively coupled and absorbed by the small workpiece.

Brazing and Soldering

Brazing and soldering require rapidly heating a very specific joint area to melt a filler alloy. High frequency provides this intense, localized heat, creating a strong bond without distorting or damaging the surrounding components.

Pre-heating for Welding

Similarly, pre-heating a weld zone can improve weld quality and reduce stress. High frequency allows for rapid and precise pre-heating of just the area to be welded.

Understanding the Trade-offs of High Frequency

While powerful, high frequency is not a universal solution. Its use comes with critical trade-offs that make it unsuitable for other common furnace applications.

The Challenge of Deep Melting

High frequency is extremely inefficient for melting large volumes of metal from a solid state. Because it only heats the surface, it would take an enormous amount of time and energy for the heat to conduct to the center of a large crucible. This is the domain of low and medium-frequency furnaces, which ensure the entire metal charge is heated uniformly.

Equipment Complexity and Coil Design

High-frequency power supplies are typically solid-state inverters, which can be more complex than the simple line-frequency or motor-generator sets used for lower frequencies. Furthermore, the efficiency of high-frequency heating is highly dependent on a small, precise gap between the coil and the workpiece, demanding more careful engineering and setup.

Choosing the Right Frequency for Your Process

Your decision must be guided by the specific metallurgical outcome you need to achieve. Selecting the wrong frequency will lead to inefficiency, poor product quality, or process failure.

- If your primary focus is surface hardening, brazing, or heating thin parts: High frequency is the correct choice to deliver precise, shallow, and rapid heating.

- If your primary focus is melting large volumes of metal: A low or medium frequency is required for deep current penetration and efficient, uniform bulk heating.

- If your primary focus is through-heating for forging medium-to-large parts: A medium frequency often provides the best balance between a reasonable heating time and a uniform temperature profile.

Ultimately, mastering frequency selection is the key to unlocking precise control over your induction heating process.

Summary Table:

| Application | Recommended Frequency Range | Key Benefit |

|---|---|---|

| Surface Hardening | 50 kHz - 400 kHz | Shallow, rapid heating for wear-resistant surfaces |

| Brazing & Soldering | 50 kHz - 400 kHz | Localized heat for strong joints without distortion |

| Heating Thin/Small Parts | 50 kHz - 400 kHz | Efficient energy coupling for small components |

| Deep Melting | 50 Hz - 3 kHz | Uniform bulk heating for large volumes |

| Through-Heating for Forging | 3 kHz - 10 kHz | Balanced penetration and heating time |

Need precise control over your induction heating process? KINTEK specializes in high-frequency induction furnaces and lab equipment for surface hardening, brazing, and heating thin materials. Our solutions deliver rapid, localized heating with exceptional accuracy—perfect for laboratories and industrial applications requiring shallow heat treatment. Contact our experts today to discuss how our high-frequency technology can optimize your process efficiency and product quality!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary product manufactured by an electric induction furnace? It's a State of Matter, Not a Final Product

- What temperature does steel liquify? Understanding the Melting Range for Your Applications

- What is the VAR process of steel? Achieve Superior Purity and Performance for Critical Components

- What are the limitations of induction heating? Understanding Its Material and Cost Constraints

- What is the purpose of induction furnace? Achieve Clean, Efficient Metal Melting

- What is the function of vacuum induction melting? Precision Preparation for Ni–20Cr–5Al Model Alloys

- What is the production of steel by EAF? A Guide to Modern, Recycled Steelmaking

- What are the factors that affect melting? Master Temperature, Pressure & Chemistry for High-Quality Results