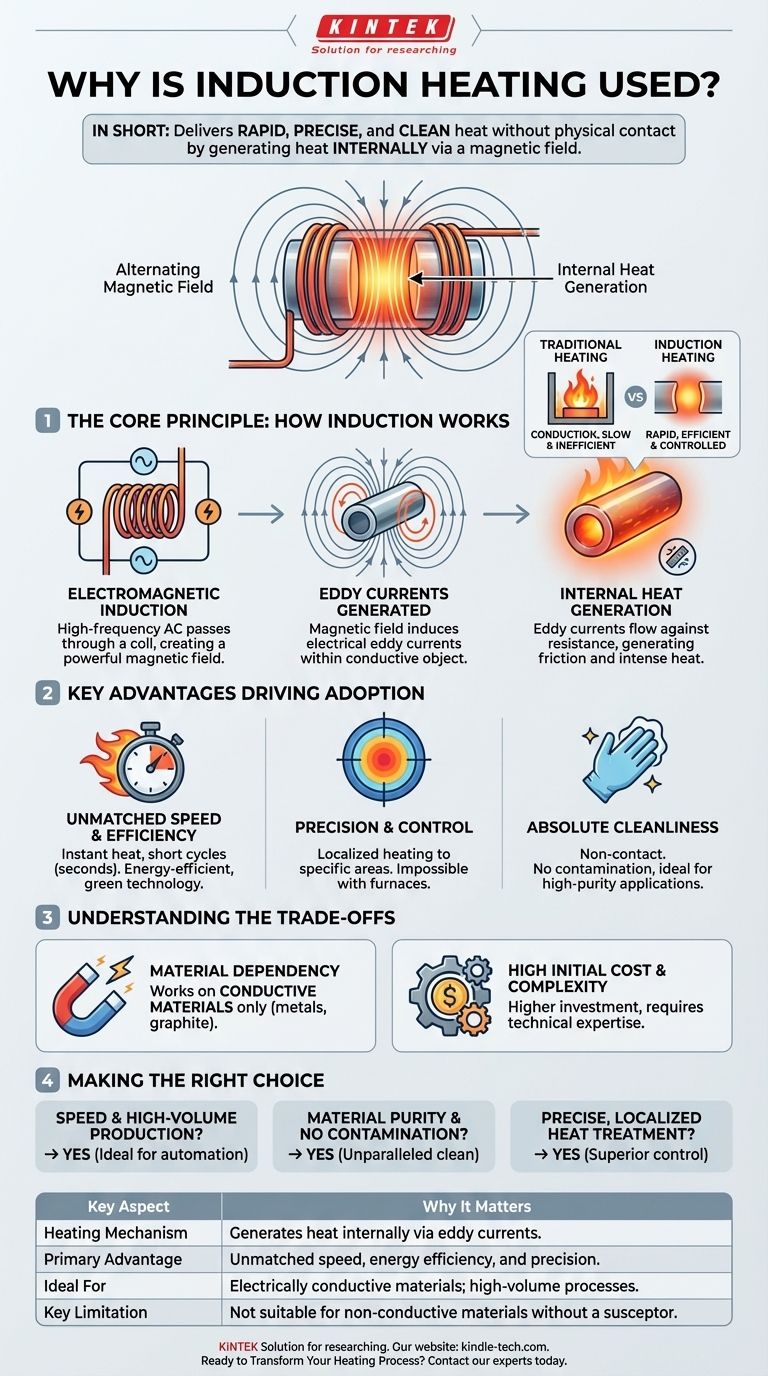

In short, induction heating is used for its unique ability to deliver rapid, precise, and clean heat without any physical contact. It works by using an alternating magnetic field to generate heat directly inside a conductive material, which makes it fundamentally different from traditional heating methods that apply heat from an external source like a flame.

The core reason induction heating is so effective is that it bypasses conventional heat transfer. Instead of slowly conducting heat from the outside-in, it generates heat internally within the object itself, leading to unparalleled speed, efficiency, and control.

The Core Principle: How Induction Generates Internal Heat

To understand why induction is chosen, you must first understand its mechanism. It isn't magic; it's a direct application of electromagnetic principles.

Electromagnetic Induction at Work

An induction heating system uses a high-frequency alternating current (AC) passed through a specially designed coil, typically made of copper.

This current in the coil generates a powerful and rapidly changing magnetic field around it.

When a conductive object, like a piece of steel, is placed within this magnetic field, the field induces electrical currents inside the object itself.

The Role of Eddy Currents

These induced currents are known as eddy currents.

As the eddy currents flow through the material against its natural electrical resistance, they generate immense friction and, therefore, intense heat.

This is the entire basis for induction heating—turning electrical energy into a magnetic field, and then back into heat energy inside the target part.

Why This Is a Game-Changer

Traditional furnaces rely on conduction, slowly transferring heat from the outside surface of an object to its core. This is slow and inefficient.

Induction generates the heat inside the object. This allows for extremely rapid temperature increases, as there is no need to wait for heat to travel through the material.

Key Advantages Driving Adoption

The unique internal heating mechanism gives rise to several powerful advantages that make it indispensable in many industrial processes.

Unmatched Speed and Efficiency

Because heat is generated instantly and directly where it's needed, heating cycles are incredibly short, often taking seconds instead of minutes or hours.

Furthermore, since the system doesn't heat the surrounding atmosphere—only the part itself—very little energy is wasted, making it a highly energy-efficient and environmentally friendly ("green") technology.

Precision and Control

The magnetic field can be precisely controlled by the shape of the coil and the frequency of the current.

This allows heat to be applied to very specific areas of a part, leaving other areas unaffected. This level of localized control is impossible to achieve with a furnace or a torch.

Absolute Cleanliness

The heating process is non-contact. The part never touches a flame or a heating element.

This eliminates any possibility of contamination from combustion byproducts or contact materials, which is a critical requirement in semiconductor manufacturing, medical applications, and high-purity metallurgy.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Its effectiveness is governed by specific physical principles that create limitations.

Material Dependency

The primary limitation is that induction heating only works directly on electrically conductive materials, such as metals like steel, copper, and aluminum, or semiconductors like graphite.

Non-conductive materials like plastics, ceramics, or glass cannot be heated directly by induction unless a conductive susceptor is used to transfer heat to them.

High Initial Cost and Complexity

The initial capital investment for an induction heating system—including the power supply and custom-designed coils—is typically higher than for a conventional furnace.

Designing and tuning the coil for a specific application requires significant technical expertise to ensure an efficient and uniform heating pattern.

Making the Right Choice for Your Goal

Selecting induction heating depends entirely on whether its unique advantages align with your process priorities.

- If your primary focus is speed and high-volume production: Induction is the ideal choice for its rapid, repeatable heating cycles that integrate seamlessly into automated manufacturing lines.

- If your primary focus is material purity and avoiding contamination: The clean, non-contact nature of induction is unparalleled for industries like semiconductor manufacturing or medical device fabrication.

- If your primary focus is precise, localized heat treatment: Induction offers superior control for tasks like surface hardening gears or brazing specific joints without affecting the entire part.

By generating heat from within, induction heating provides a level of speed and precision that fundamentally transforms modern manufacturing processes.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Heating Mechanism | Generates heat internally via eddy currents, not from an external source. |

| Primary Advantage | Unmatched speed, energy efficiency, and precise localized control. |

| Ideal For | Electrically conductive materials (metals, graphite); high-volume, automated processes. |

| Key Limitation | Not suitable for non-conductive materials (plastics, glass) without a susceptor. |

Ready to Transform Your Heating Process with Unmatched Speed and Precision?

If your goals include faster production cycles, superior process control, or absolute material purity, induction heating is the solution. KINTEK specializes in advanced lab equipment and consumables, providing the right tools to meet your laboratory's specific needs.

Contact our experts today to discuss how our induction heating solutions can enhance your efficiency and product quality.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- What is the temperature range of molybdenum disilicide heating elements? Choose the Right Grade for Your High-Temp Needs