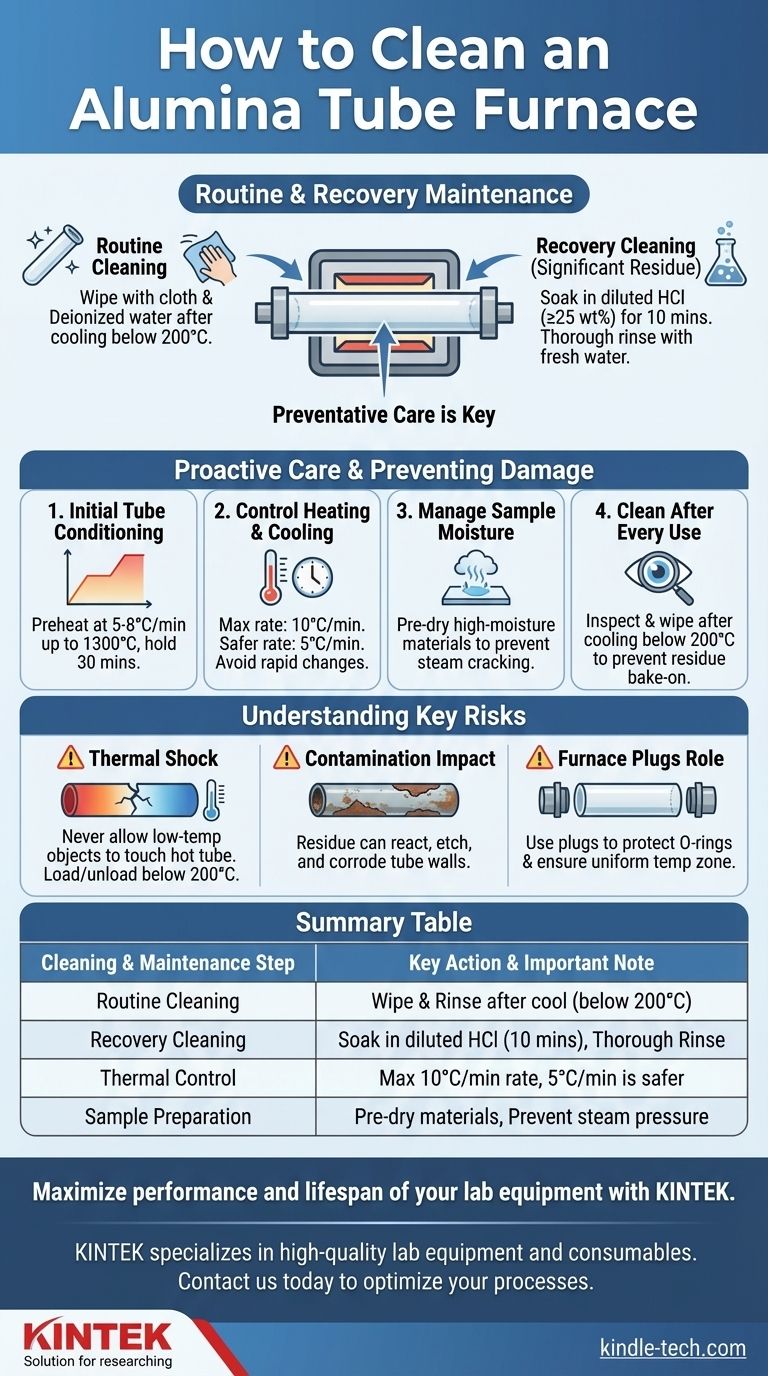

For routine cleaning, you should physically wipe out any residue after the alumina tube has cooled and, if necessary, rinse it with deionized water. For more significant contamination, the tube can be soaked in diluted hydrochloric acid (≥25 wt%) for approximately 10 minutes, followed by a thorough rinse with fresh water to remove all traces of acid.

The most effective way to "clean" an alumina tube is to prevent it from getting dirty in the first place. Proper operational procedures, especially controlling thermal shock and pre-treating samples, are far more critical to the tube's longevity than any reactive cleaning method.

The Standard Recovery Cleaning Procedure

When preventative measures are not enough and significant residue remains, a chemical wash may be necessary. This should be seen as a recovery operation, not routine maintenance.

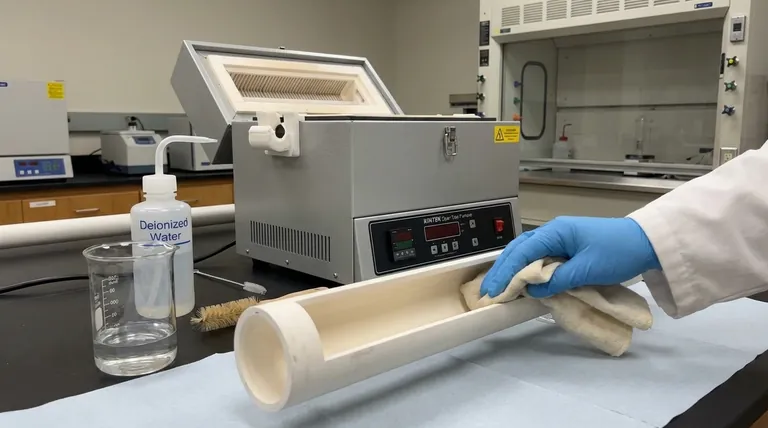

Step 1: Prepare the Tube

First, ensure the furnace is completely cool and turned off. Carefully remove the alumina tube from the furnace and place it on a clean, stable, and chemically-resistant surface.

Step 2: The Acid Wash

Fill the tube with a diluted hydrochloric acid solution (HCl, ≥25 wt%). Allow it to soak for about 10 minutes. This process helps dissolve metallic oxides and other common contaminants without being overly aggressive to the alumina itself.

Step 3: Thorough Rinsing and Drying

After soaking, safely drain the acid. Rinse the tube interior thoroughly with fresh, clean water—preferably deionized water—to remove any residual acid. Allow the tube to dry completely before reinserting it into the furnace to prevent rapid steam generation and potential cracking upon heating.

Proactive Care: Preventing Contamination and Damage

The best strategy is to establish strict operational protocols that protect the tube from the start. A clean process negates the need for aggressive cleaning.

Initial Tube Conditioning

When using a new alumina tube, it must be preheated to eliminate internal stresses and burn off any manufacturing pollutants. A slow heating rate of 5-8°C per minute up to 1300°C, held for 30 minutes, is recommended for this initial conditioning.

Control Your Heating and Cooling

Rapid temperature changes are the primary cause of tube failure. The heating and cooling rates for your processes should never exceed 10°C per minute. A conservative cooling rate of 5°C per minute is even safer and will significantly extend the life of the tube.

Manage Sample Moisture

Moisture is a significant risk. Any water trapped in your sample will turn to high-pressure steam upon heating, which can crack the tube. Always pre-dry materials with high water content or crystal water before placing them in the furnace.

Clean After Every Use

Once the furnace has cooled below 200°C, inspect the tube. Ensure no sample residue remains. A simple wipe-down or quick rinse can prevent material from baking onto the tube wall in a subsequent run, which can cause chemical corrosion and damage.

Understanding the Key Risks

Improper handling is more likely to destroy a tube than any chemical process run within it. Understanding these risks is fundamental to proper maintenance.

The Danger of Thermal Shock

Thermal shock is the single greatest threat to your alumina tube. It occurs when different parts of the tube expand or contract at different rates, causing stress fractures.

To prevent this, never allow low-temperature objects to touch a hot furnace tube. Always load and unload your samples when the furnace temperature is below 200°C.

The Impact of Contamination

Leaving sample residue inside the tube is not just a cleanliness issue. At high temperatures, that residue can react with the alumina, creating new compounds that can etch, corrode, or weaken the tube wall over time.

The Role of Furnace Plugs

Alumina furnace plugs should be placed at both ends of the tube. Their purpose is to create a more uniform temperature zone and prevent the hot zone from extending to the ends of the tube. This protects the sealing O-rings from heat damage, ensuring the system remains airtight.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities.

- If you are dealing with a visibly contaminated tube: Use the hydrochloric acid wash as a one-time recovery step, then implement stricter preventative protocols.

- If you are setting up a new furnace: Perform the initial conditioning heat cycle without fail and establish strict rules for heating rates and sample loading from day one.

- If your primary goal is maximum tube lifespan: Focus entirely on prevention by using slow thermal cycles, pre-drying all samples, and ensuring the tube is physically clean after every single run.

Ultimately, treating your alumina tube with care during operation is the most effective form of maintenance you can perform.

Summary Table:

| Cleaning & Maintenance Step | Key Action | Important Note |

|---|---|---|

| Routine Cleaning | Wipe with cloth, rinse with deionized water. | Perform after tube cools below 200°C. |

| Recovery Cleaning | Soak in diluted HCl (≥25 wt%) for 10 mins. | Rinse thoroughly with water afterward. |

| Thermal Control | Heating/Cooling rate should not exceed 10°C/min. | A rate of 5°C/min is safer for tube longevity. |

| Sample Preparation | Pre-dry materials with high moisture content. | Prevents steam pressure from cracking the tube. |

Maximize the performance and lifespan of your lab equipment with KINTEK.

Proper maintenance is key to protecting your investment. Whether you're using an alumina tube furnace or other critical lab equipment, having the right tools and consumables ensures reliable results. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs.

Let our experts help you optimize your processes. Contact us today to discuss your specific requirements and discover how we can support your laboratory's success.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How does a laboratory tube furnace contribute to the synthesis of RuO2 catalysts? Master Thermal Precision.

- What role does an industrial tube furnace play in the synthesis of Fe@N-BC catalysts? Precision Thermal Control Guide

- What critical conditions does a high-temperature tube furnace provide? Optimize Melt-Casting for Solid-State Batteries

- Is quartz a resistant mineral? Discover the Two Forms of Quartz and Their Unique Strengths

- What are the advantages of using quartz glass tube reactors for ammonia decomposition? Ensure Pure Catalyst Screening

- Why is a tube furnace required for Se/PPS mercury removal? Optimize Thermal Control for Flue Gas Research

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- What process conditions does a tube furnace provide for LATP solid-state electrolytes? Optimize Your NASICON Synthesis