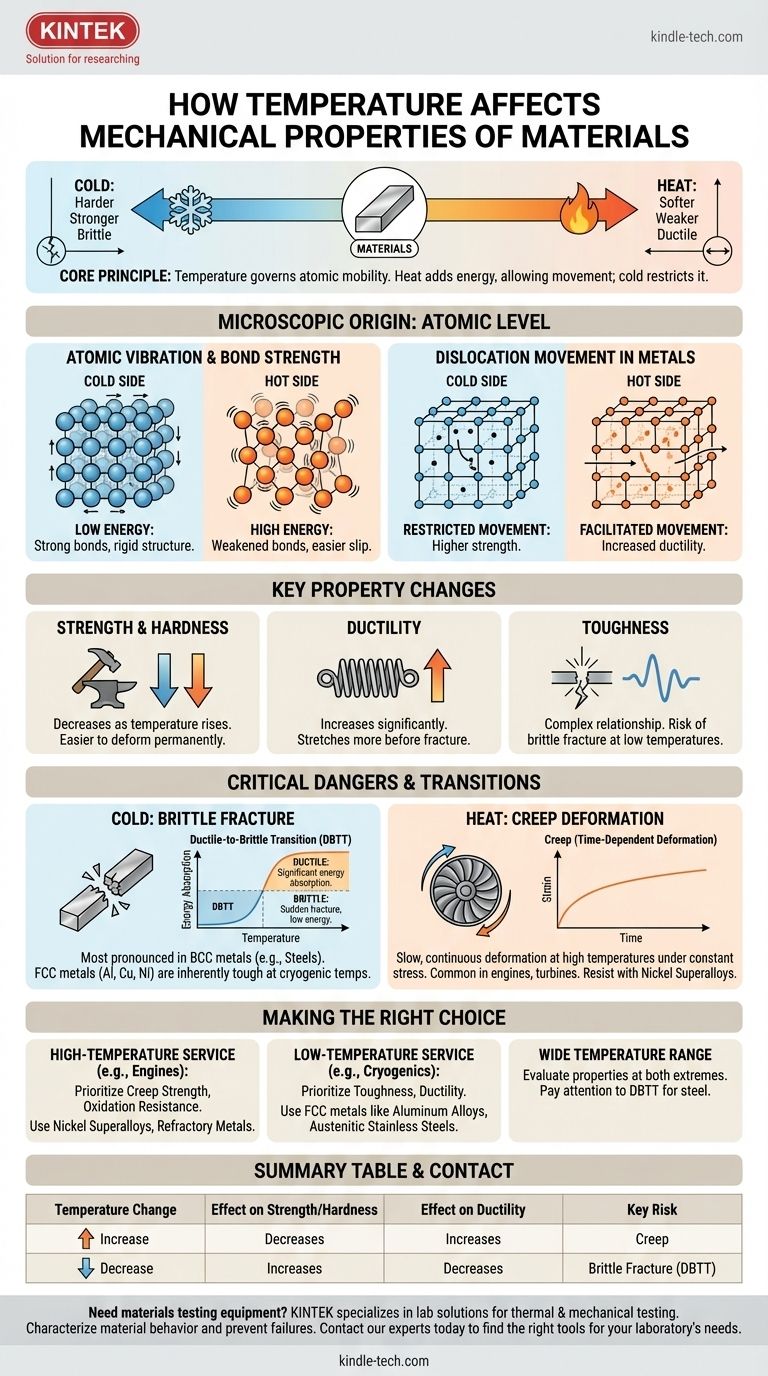

In short, temperature fundamentally alters a material's mechanical behavior. As a general rule, increasing temperature makes most materials softer, weaker, and more ductile (able to stretch without breaking). Conversely, decreasing temperature tends to make them harder, stronger, and more brittle (prone to fracturing with little warning).

The core principle is that temperature governs atomic and molecular mobility. Heat provides the energy for atoms and polymer chains to move, slip, and rearrange, while cold restricts this movement, leading to vastly different responses under stress.

The Microscopic Origin of Temperature Effects

To understand why temperature has such a profound impact, we must look at the atomic level. A material's properties are a direct result of how its atoms and molecules interact.

Atomic Vibration and Bond Strength

Every atom in a solid material is in a constant state of vibration. Temperature is a measure of this kinetic energy.

When you heat a material, you increase this atomic vibration. The atoms push against each other more forcefully, effectively weakening the bonds holding them in a rigid structure. This makes it easier for atoms to slip past one another when a force is applied.

Dislocation Movement in Metals

In crystalline materials like metals, deformation under load occurs through the movement of line defects called dislocations.

Higher temperatures provide thermal energy that helps these dislocations move and overcome obstacles within the crystal lattice. This facilitated movement is why a metal becomes easier to bend and shape when hot.

How Key Mechanical Properties Change

The changes at the atomic level manifest as predictable shifts in the macroscopic properties we measure and design for.

Strength and Hardness

Yield strength (the stress at which a material begins to deform permanently) and ultimate tensile strength (the maximum stress it can withstand) both decrease as temperature rises.

Because the atomic bonds are weaker and dislocations move more easily, less force is required to initiate and sustain plastic deformation. Hardness, which is a measure of resistance to localized deformation, follows the same trend.

Ductility

Ductility is a measure of how much a material can deform before it fractures, often measured as percent elongation.

For most metals, ductility increases significantly with temperature. The increased atomic mobility allows the material to stretch and rearrange its internal structure to accommodate the stress, delaying fracture.

Toughness

Toughness is a material's ability to absorb energy and deform without fracturing. The relationship between temperature and toughness is more complex and leads to one of the most critical failure modes in engineering.

While materials become more ductile at high temperatures, it is the loss of toughness at low temperatures that poses the greatest risk.

The Critical Danger of Cold: Brittle Fracture

For a large class of materials, particularly common steels, there is a temperature below which their behavior changes catastrophically.

Understanding the Ductile-to-Brittle Transition

Many materials exhibit a Ductile-to-Brittle Transition Temperature (DBTT). Above this temperature, the material fails in a ductile manner, absorbing significant energy.

Below the DBTT, the same material will fail in a brittle manner, fracturing suddenly with very little energy absorption. This type of failure is dangerous because it occurs without warning.

The Role of Crystal Structure

This transition is most pronounced in metals with a Body-Centered Cubic (BCC) crystal structure, such as carbon and low-alloy steels.

Metals with a Face-Centered Cubic (FCC) structure, like aluminum, copper, and nickel alloys, do not exhibit a sharp DBTT. This makes them inherently better suited for cryogenic and very low-temperature applications.

The Challenge of Sustained Heat: Creep

At the other end of the spectrum, high temperatures introduce a different time-dependent failure mechanism.

What is Creep?

Creep is the slow, continuous deformation of a material under a constant stress at high temperatures (typically above 40% of its melting temperature).

Even if the applied stress is well below the material's yield strength, the material can slowly stretch over time, eventually leading to failure. This is a primary concern in jet engines, power plant turbines, and steam pipes.

Designing for Creep Resistance

Materials designed for high-temperature service, such as nickel-based superalloys, are specifically engineered with microstructures that resist dislocation movement and atomic diffusion, thereby minimizing the rate of creep.

Making the Right Choice for Your Application

Understanding these principles is not academic; it is essential for preventing catastrophic failure and ensuring reliability.

- If your primary focus is high-temperature service (e.g., engines, furnaces): Prioritize materials with high creep strength and oxidation resistance, like nickel superalloys or refractory metals.

- If your primary focus is low-temperature or cryogenic service (e.g., LNG tanks): You must select materials that remain tough and ductile at the operating temperature, such as FCC metals like aluminum alloys or austenitic stainless steels.

- If your application involves a wide temperature range: Carefully evaluate the material's properties at both extremes, paying special attention to the DBTT for any steel components.

Ultimately, selecting the right material requires a clear understanding of its behavior across its entire service temperature range.

Summary Table:

| Temperature Change | Effect on Strength/Hardness | Effect on Ductility | Key Risk |

|---|---|---|---|

| Increase | Decreases | Increases | Creep (time-dependent deformation) |

| Decrease | Increases | Decreases | Brittle Fracture (Ductile-to-Brittle Transition) |

Need materials testing equipment to ensure your components perform safely across their entire temperature range? KINTEK specializes in lab equipment and consumables for thermal analysis and mechanical testing. Our solutions help you characterize material behavior, identify critical transition temperatures, and prevent failures. Contact our experts today to find the right tools for your laboratory's needs.

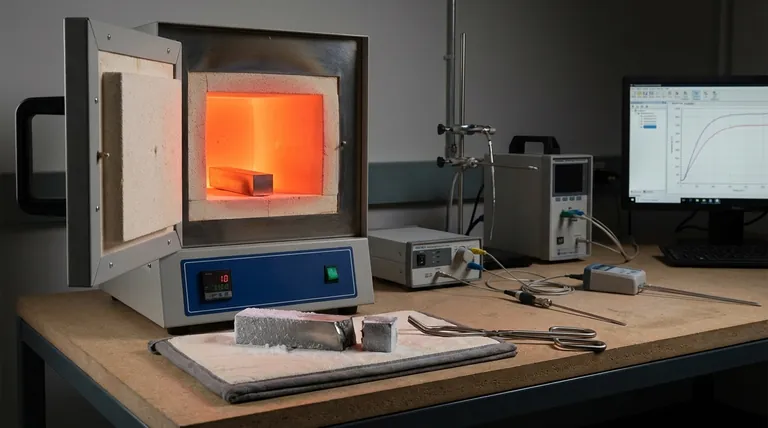

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the best steel for high temperature applications? Choose the Right Material for Extreme Heat

- What is the use of sputter coating? Achieve Superior Thin-Film Deposition for Your Lab

- How does heat treatment prevent corrosion? Achieve Uniform Microstructure to Block Corrosive Attack

- Why is a constant temperature orbital shaker essential for bioleaching? Optimize Enargite Mineral Recovery Today

- Which is used for elemental analysis? XRF for Fast, Non-Destructive Material Testing

- What role does an ultrasonic homogenizer play in the preparation of nickel nanoparticle colloids? Enhance Dispersion

- Why does the selection of high-quality consumables impact SEM analysis? Unlock Precision for Austenitic Stainless Steels

- What are the limitations and disadvantages of powder metallurgy? Understanding the Trade-Offs for Your Application